Bending and twisting combined soft robot module

A robot and bending technology, applied in the field of robots, to achieve the effect of reducing redundancy, ensuring stability, and high efficiency of action execution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

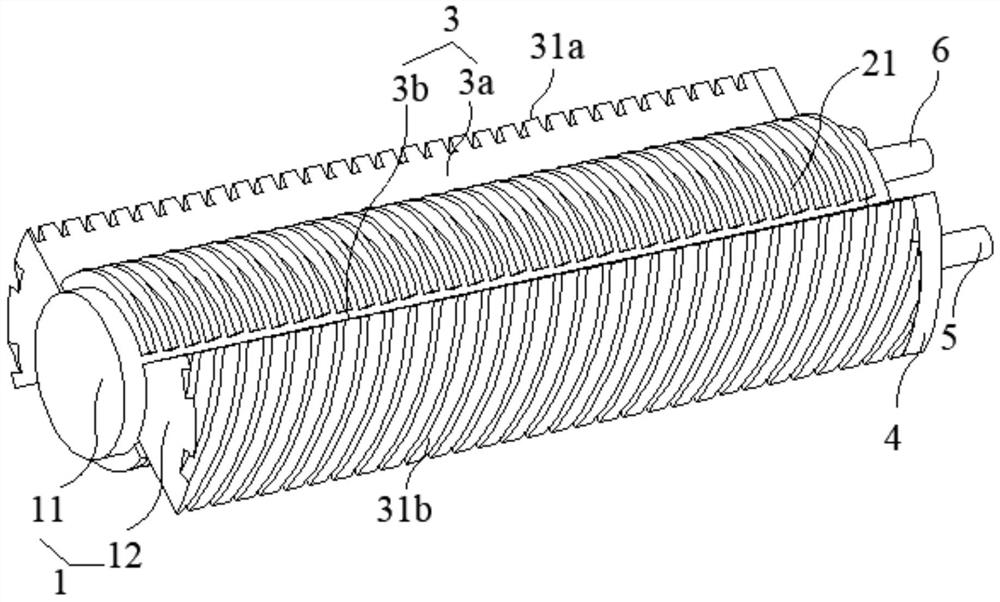

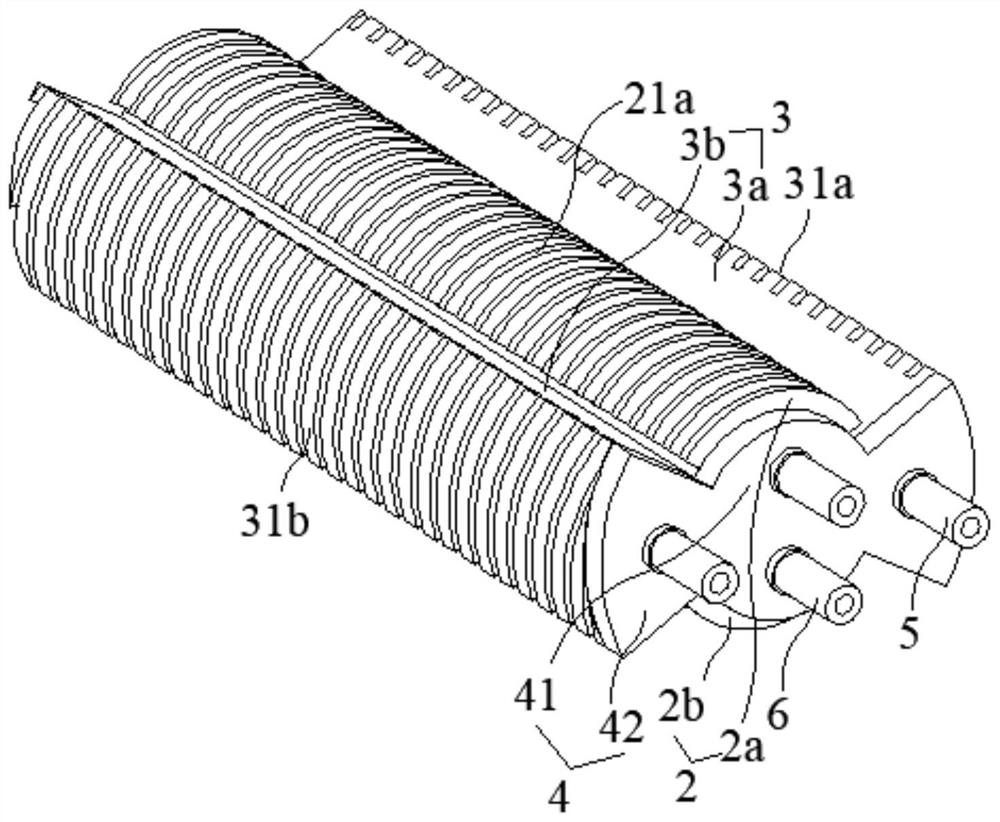

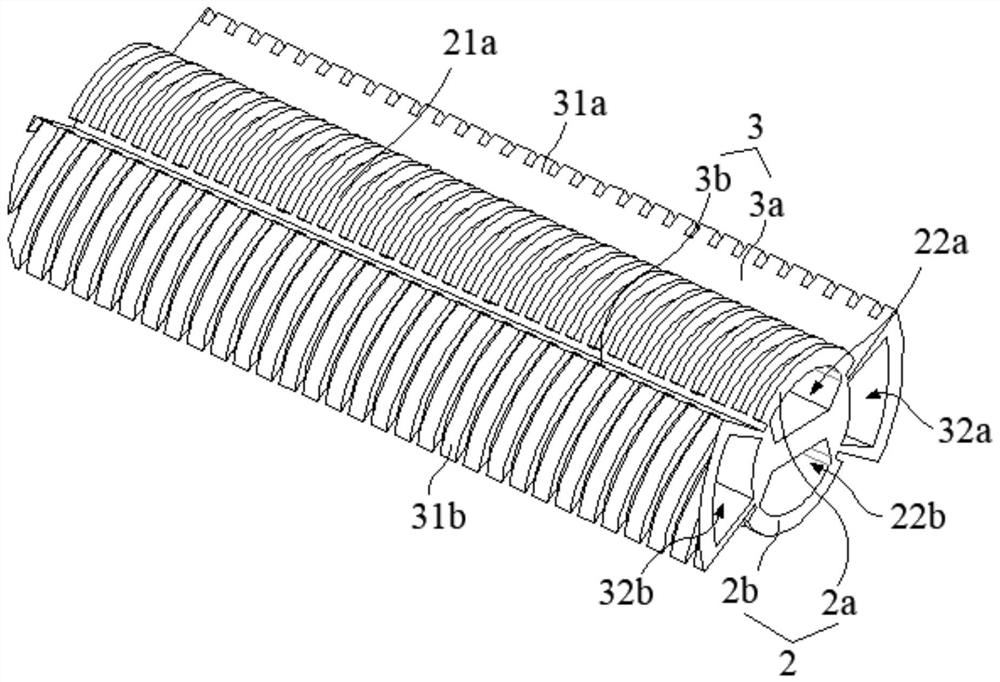

[0037] see Figure 1-4 , figure 1 and figure 2 The three-dimensional structural schematic diagrams of different viewing angles of the bending-twisting combined soft robot module of this embodiment are shown respectively, image 3 It shows the three-dimensional structural diagram of the soft robot module combined with bending and torsion in this embodiment after removing the bottom connecting plate, Figure 4 show image 3 right view of . see Figure 1-4 The soft robot module combined with bending and torsion in this embodiment includes a bending and torsion structure, a top connection plate 1 and a bottom connection plate 4 respectively arranged at both ends of the bending and torsion structure, and an external trachea arranged on the bottom connection plate 4 . The soft robot module combined with bending and torsion in this embodiment can simultaneously realize bending and torsion motion effects under the same module, and it is not necessary to control the bending and ...

Embodiment 2

[0049] see Figure 5 , this embodiment introduces a deformation structure of a soft robot module combined with bending and twisting. Compared with the soft robot module combining bending and twisting in Embodiment 1, the main difference is mainly the bending body 2 (including bending units 2a, 2b) The structure is different, and the other structures are basically the same. In this embodiment, the curved main body 2 may have a bellows structure, for example, and the left and right sides of the curved main body 2 of the bellows-shaped structure respectively protrude outward to form fan-shaped columnar torsion units 3a, 3b, so that the curved main body 2 passes through The plane of symmetry ( Figure 4 The horizontal plane passing through the axis Z1) is divided into two symmetrically arranged upper and lower parts, which are respectively used as bending units 2a and 2b. The outer wall of the bending unit 2a / 2b is composed of several corrugated joints 21a' / 21b' arranged sequent...

Embodiment 3

[0051] see Figure 6, this embodiment introduces another deformed structure of a soft robot module combined with bending and twisting. Compared with the soft robot module combining bending and twisting in Embodiment 1, the main difference is that the structure of the bending body 2 is different, and other structures are basically the same . In this embodiment, the curved body 2 is composed of a curved unit 2a and a curved unit 2b with two opposite bottom surfaces. The curved unit 2a and the curved unit 2b have a wave-shaped non-rotating body structure. The curved unit 2a The bottom surfaces of the bending units 2b are connected by an intermediate connection surface 7, and two fan-shaped columnar torsion units 3a, 3b protrude outward from the two sides of the intermediate connection surface 7. The outer wall of the bending unit 2a / 2b is composed of crest structures 21a" / 21b" and trough structures arranged at intervals along the axial direction of the soft robot module combined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com