Automatic suction device for label paper

A suction device and label paper technology, applied in labeling, packaging, labeling machines, etc., can solve problems that are prone to food, hygiene and safety, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below through specific examples.

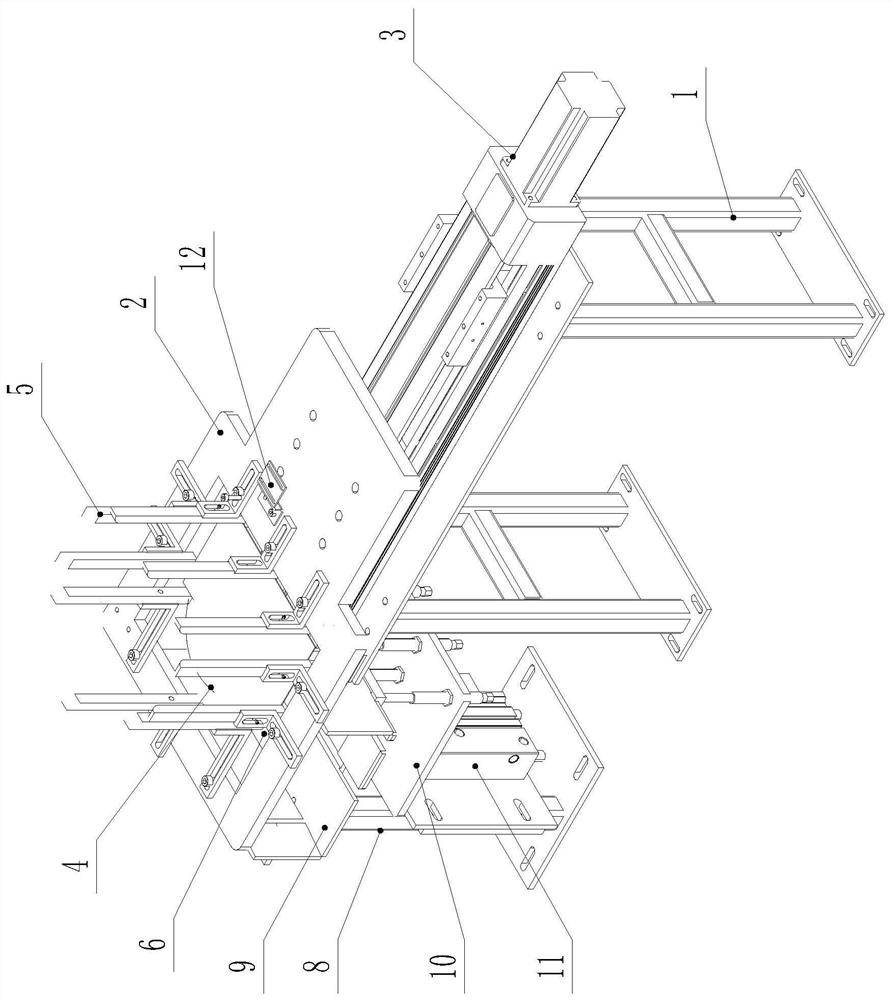

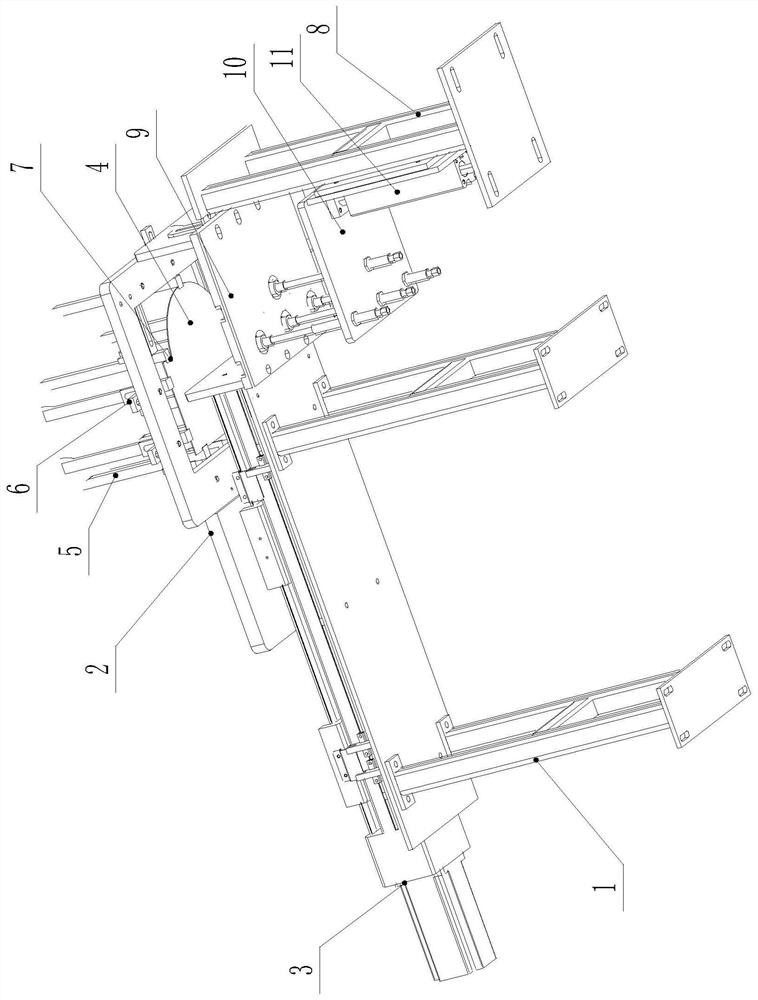

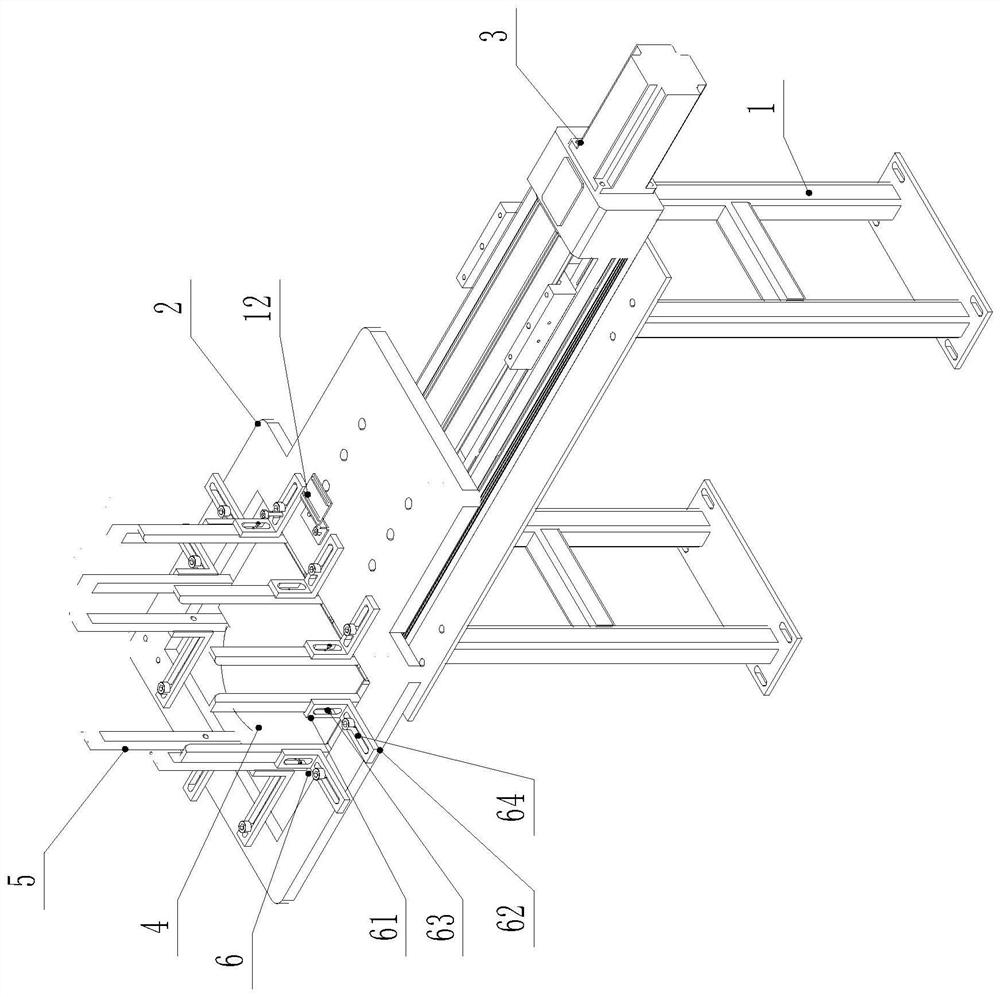

[0034] Such as Figure 1-5As shown, an automatic suction device for label paper, including a storage device for storing label paper and a retrieving mechanism for sucking label paper; the storage device includes a storage rack 1, and a storage material is slidably installed on the storage rack 1 Platform 2, the material storage platform 2 is driven by the linear power device 3 to slide between the avoidance station and the reclaiming station, the material storage platform 2 is provided with a reclaimer port 4, and a convenient label paper stack is provided above the material storage platform 2 To the material storage frame, the bottom of the material storage platform 2 is located around the reclaimer 4 and is provided with a support structure supporting the edge of the label paper; the reclaimer mechanism includes a reclaimer base 8 on which the reclaimer An assembly groove sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com