Composite beam

A technology of composite beams and steel beams, applied in the field of composite beams, can solve problems such as unfavorable negative bending moments, and achieve the effects of preventing cracking and damage, reducing bridge construction costs, and solving unfavorable forces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

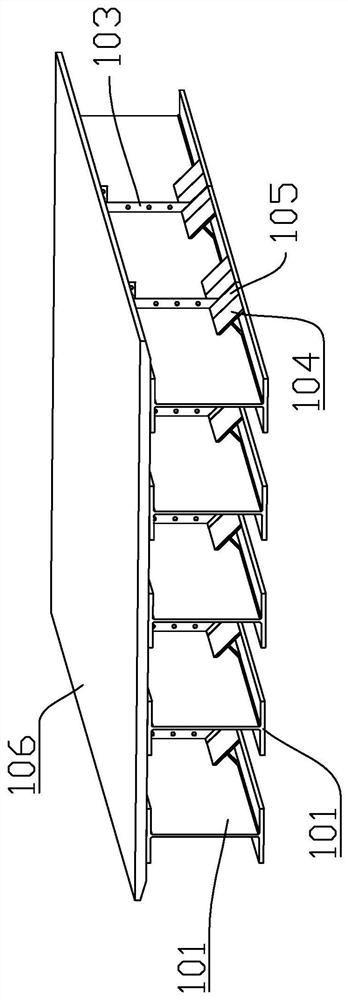

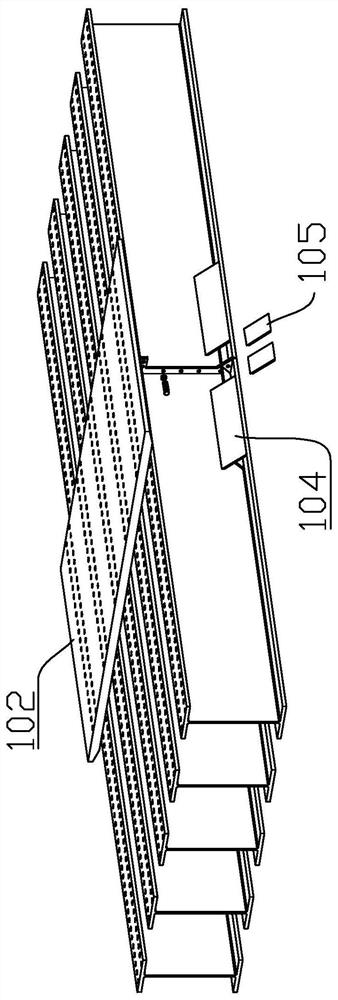

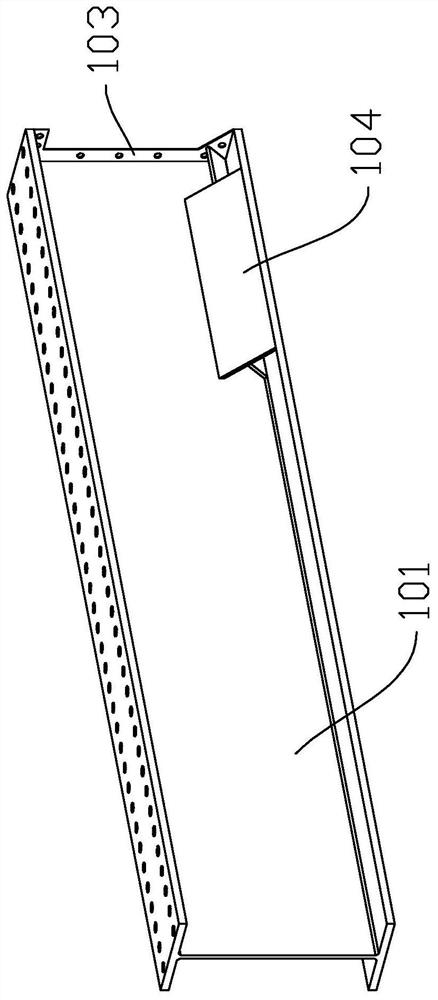

[0032] The invention relates to a composite beam. The composite beam adopts a steel-concrete composite structure to form an assembled simple-support variable continuous composite beam. The composite beam includes at least two span beam sections, and the span beam sections are provided with a bridge deck and a plurality of steel beams 101 It can be understood that the steel girders 101 are arranged side by side on the span section, the bridge deck is paved on the steel girders 101, the asphalt layer 106 is arranged on the composite beam, and the asphalt layer 106 is poured on the bridge deck. Further, the steel beam 101 is set as H-shaped steel.

[0033] The lower edge of the steel beam 101 is provided with a stiffening box 104. The stiffening box 104 is made of steel. The steel structure beam, the variable cross-section beam increases the compression area of the lower edge of the section near the fulcrum, enhances the compression stability, and enhances the compression resis...

Embodiment 2

[0045] The difference between the present embodiment and the second embodiment is that two adjacent span beam sections are connected by a concrete structure. Specifically, in two adjacent span beam sections, two paired steel beams 101 are connected by a concrete structure, a part of the concrete structure is fixed to one of the steel beams 101 by bolts, and the other part of the concrete structure is connected to the other by bolts. The steel beam 101 is fixed, and the concrete structure includes two concrete connecting plates 108, and the two concrete connecting plates 108 are respectively arranged on both sides of the steel beam 101, and the steel beam 101 is provided with a plurality of through holes for bolts to pass through.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com