Light composite thermal insulation board convenient to install and application thereof

A technology with convenient installation and composite heat preservation, which is applied in the direction of heat preservation, climate change adaptation, sustainable waste treatment, etc., can solve the problems of cumbersome and inconvenient installation, and achieve the effect of solving cumbersome installation, improving work efficiency, and convenient installation and connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

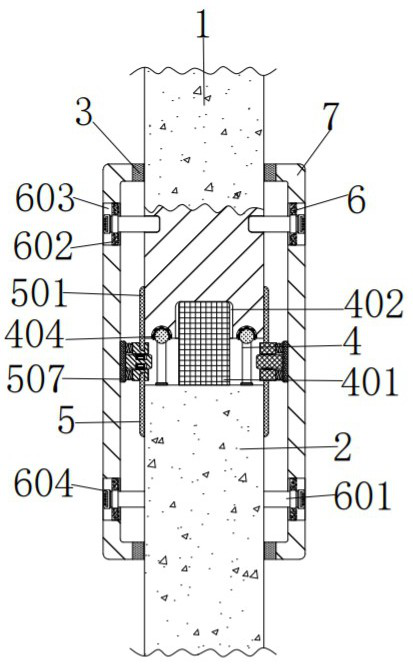

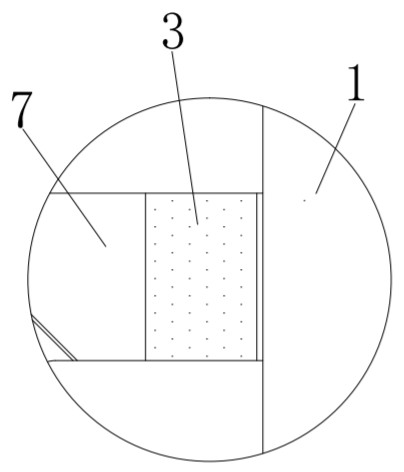

[0031] An easy-to-install lightweight composite thermal insulation board, comprising a first board 1, a second board 2 is provided below the first board 1, the inner and outer walls of the first board 1 and the second board 2 are connected with the middle inner wall of the rubber pad 3 Fitting together, the inner wall of the rubber pad 3 is affixed to the middle inner wall of the upper and lower sides of the housing 7. The rubber pad 3 seals the gap between the first plate 1 and the second plate 2 and the housing 7. The first plate 1 The installation mechanism 4 is installed below the bottom, the installation mechanism 4 comprises a vertical block 401, a first slot 402, a vertical bar 403, a locking ball 404, an elastic sheet 405, a first spring 406 and an arc groove 407, and the bottom of the vertical block 401 It is fixedly connected with the middle of the top of the second plate 2, and the top of the vertical block 401 is provided with a first card slot 402, and the upper ou...

Embodiment 2

[0033] As an option, see figure 1 , 4And 6, a lightweight composite thermal insulation board that is easy to install, the left and right ends of the first board 1 and the second board 2 are equipped with a positioning mechanism 5, the positioning mechanism 5 includes a curved rod 501, a second card slot 502, and a horizontal block 503 , slider 504, chute 505, slide plate 506, riser 507 and second spring 508, the upper right end of the curved bar 501 is fixedly connected with the lower left end of the first plate 1, the lower outer wall of the curved bar 501 is connected with the second clamping groove 502 The inner surface of the horizontal block 503 is engaged with the inner surface, and the second card slot 502 is opened on the inner wall above the right side of the horizontal block 503. The curved rod 501 on the first plate 1 is inserted into the second card slot 502 on the horizontal block 503 for positioning, and the horizontal block The bottom of 503 is provided with sl...

Embodiment 3

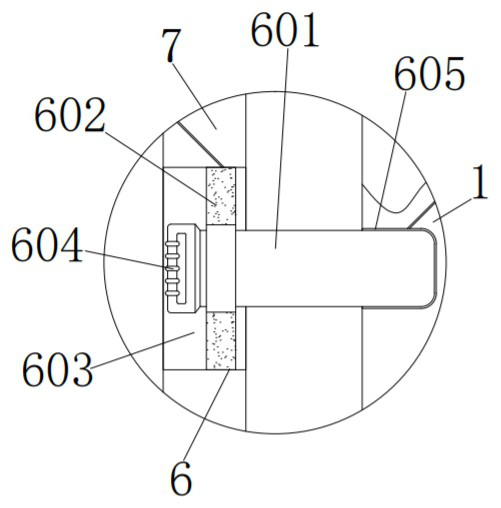

[0036] As an option, see figure 1 and 3 , a light-weight composite thermal insulation board that is easy to install, the inner sides of the first board 1 and the second board 2 are equipped with a fixing mechanism 6, and the fixing mechanism 6 includes an insertion rod 601, a rubber block 602, a groove 603, a handle 604 and The third card slot 605, the left side of the insertion rod 601 is provided with a rubber block 602, the left outer wall of the insertion rod 601 is closely attached to the middle inner wall of the rubber block 602, the outer side of the rubber block 602 is provided with a groove 603, the rubber block 602 The outer wall of the outer wall is fixedly connected with the inner surface of the right side of the groove 603. The rubber block 602 increases the friction between the insertion rod 601 and the groove 603 to prevent the insertion rod 601 from falling off. The rubber block 602 is made of hard rubber material, and the concave Groove 603 is opened on the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com