Underground karst cave model preparation method

A geological model and karst cave technology, which is applied in the field of simulation experiment technology and underground karst cave model preparation, can solve the problems of not being able to simulate the geological environment of karst caves well, and achieve the effects of fast shaping, improved accuracy, and stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1: as Figure 1 to Figure 10 Shown, a kind of underground karst cave model preparation method comprises the following steps:

[0054]Step 1. Determine the location and shape of the karst cave according to the site engineering conditions through site survey and geological data;

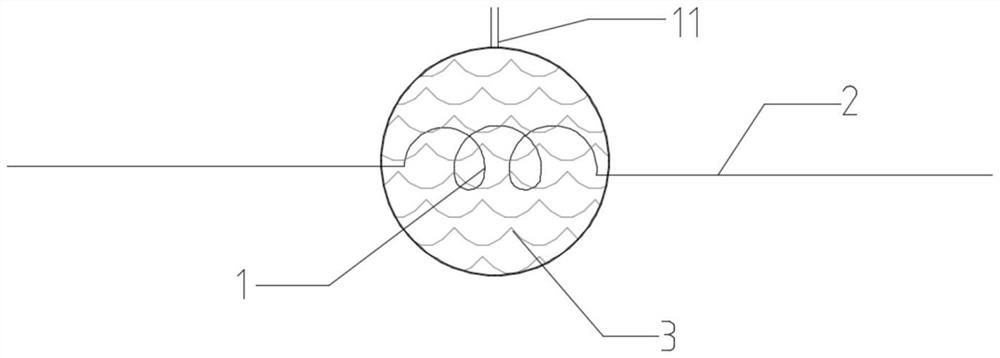

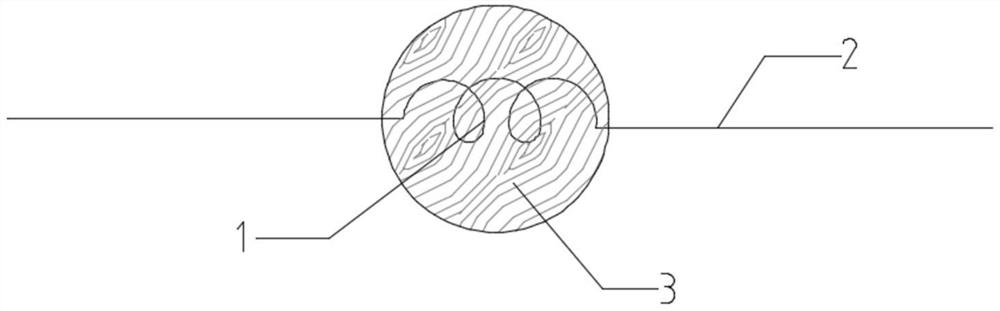

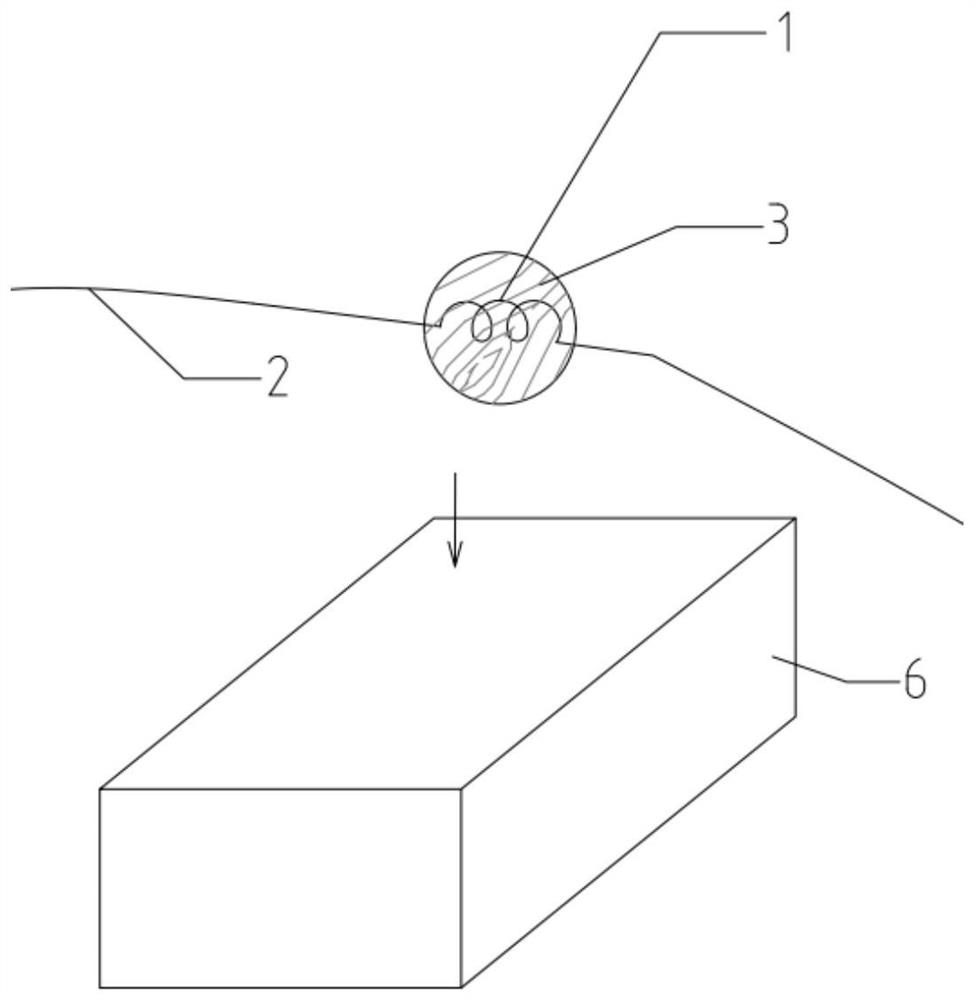

[0055] Step 2, such as figure 1 As shown, the mold 11 is made according to the shape of the cave, and the magnetorheological material 3 and the conductive coil 1 are put into the mold 11. The wire 2 is extended to the outside of the mold 11 and connected to the voltage regulator 9, and the conductive coil 1 is energized through the voltage regulator 9, and the set voltage is supplied to generate a magnetic field, so that the magnetorheological material 3 is solidified and formed, and the mold 11 is removed to obtain a cave mandrel 10, such as figure 2 As shown, in the subsequent pouring process, the conductive coil 1 is always kept in an energized state, and the cave mandrel 10 ca...

Embodiment 2

[0066] Embodiment 2: Other steps are the same as in Embodiment 1, the difference is that in step 3.2, before the karst cave mandrel 10 is installed, a protective layer is set on the conductive coil 1 and the wire 2 outside the karst cave mandrel 10, and the conductive coil 1 It is a filament coil. In step 4, after the conduction coil 1 is powered off, the conduction coil 1 is directly pulled out from the underground cave model (the spring-like conduction coil 1 becomes a filament after being pulled out), and the flow Physically, the magnetorheological material 3 also flows out of the hole of the conductive coil 1. Since the conductive coil 1 is very small, the hole left on the underground cave model after the conductive coil 1 is pulled out is very small, which is much smaller than that prepared by other methods. The holes left by the cave model basically have no effect on the structural force of the cave model.

[0067] Specifically, the protective layer is a liquid protectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com