Rock micro-defect three-dimensional reconstruction method and system

A three-dimensional reconstruction, micro-defect technology, applied in the direction of optical testing flaws/defects, measuring devices, instruments, etc., to achieve the effect of ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

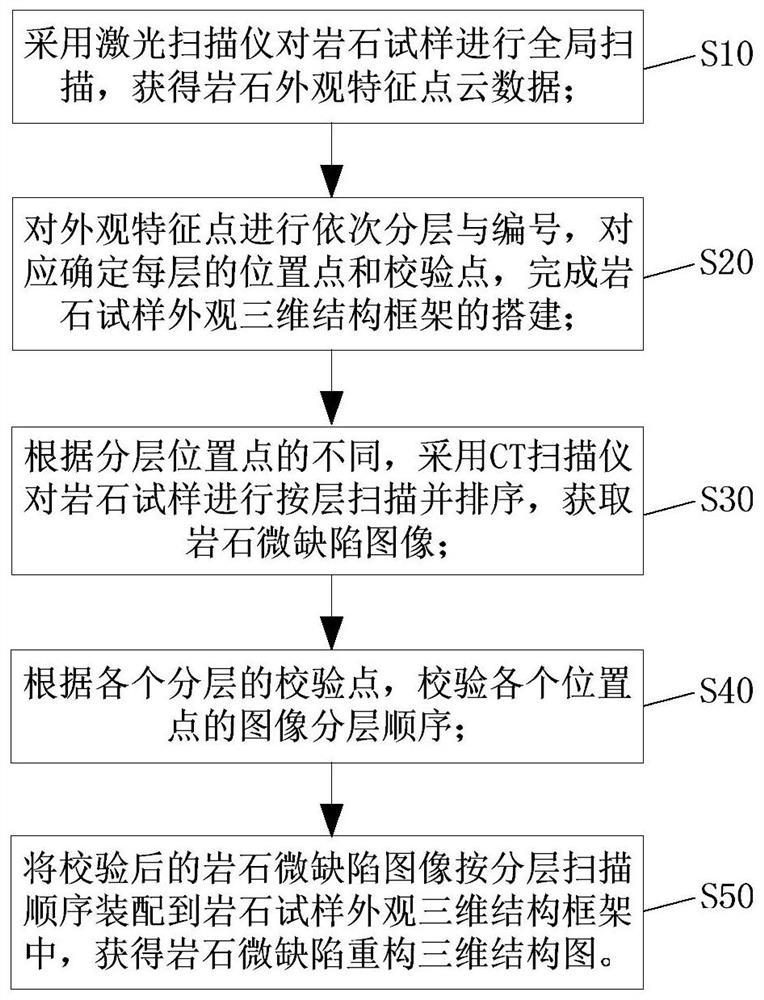

[0073] Such as figure 1 As shown, the method for three-dimensional reconstruction of rock micro-defects provided by the embodiment of the present invention includes the following steps:

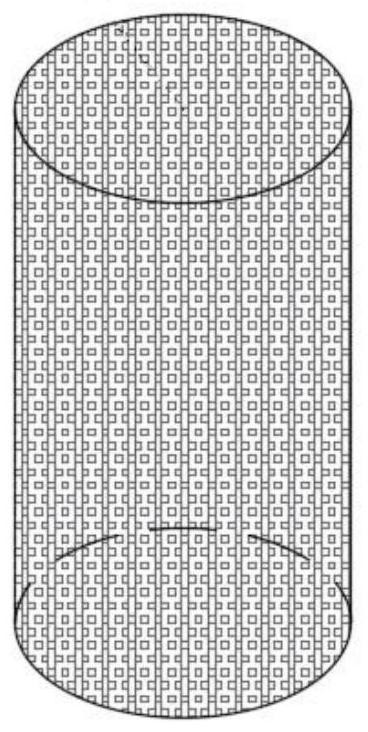

[0074] S10, using a laser scanner to globally scan the rock sample to obtain rock appearance characteristic point cloud data;

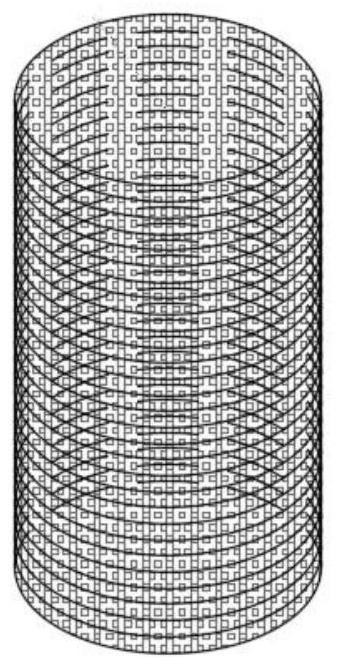

[0075] S20, sequentially layering and numbering the appearance feature points, correspondingly determining the position points and verification points of each layer, and completing the construction of the three-dimensional structural framework of the appearance of the rock sample;

[0076] S30, using a CT scanner to scan and sort the rock samples layer by layer according to different layer positions, to obtain images of rock micro-defects;

[0077] S40, according to the check point of each layer, check the image layering sequence of each position point;

[0078] S50 , assembling the checked rock micro-defect images into the three-dimensional structure framework of ...

Embodiment 2

[0083] On the basis of Example 1, the embodiment of the present invention also provides an implementation method for improving the accuracy of data acquisition, that is, before using a laser scanner to perform a global scan on the rock sample, such as Figure 5 shown, also includes the steps:

[0084] S60, evenly distributing spherical targets around the rock sample.

[0085] Specifically, at least 3 pairs of staggered targets are set between adjacent stations that collect data: on the one hand, it is necessary to ensure that there are no less than 3 pairs of targets between every two adjacent stations that collect data, so as to ensure that the experimental The accuracy of the data collected during the process; on the other hand, the spherical targets on the rock samples should be staggered as much as possible to avoid placing them on the same straight line, so as to facilitate the registration of adjacent data points with the same name in the later stage.

[0086] In order ...

Embodiment 3

[0090] On the basis of Embodiment 1, the embodiment of the present invention provides an implementation manner in which the sharpness of the image outline does not meet the requirements and affects the accuracy of the three-dimensional reconstruction. Specifically, in step S30, after using a CT scanner to scan and sort by layer, as Figure 7 shown, also includes the steps:

[0091] S31, performing binarization processing on the scanned and sorted rock micro-defect image data;

[0092] S32, check one by one whether the binarized images of each layered position point meet the requirements of three-dimensional reconstruction for image contour clarity: if not, bring the layer number corresponding to the layered position point into the CT scanner to specify the position Secondary scanning to obtain and replace images that meet the contour definition requirements;

[0093] S33. Correspondingly update the position point and check point of the replaced image, and verify the image la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com