Concrete dam cable crane warehousing track planning and control method

A trajectory planning and control method technology, applied in adaptive control, general control system, non-electric variable control, etc., can solve problems such as high operating frequency, low efficiency, and limited construction environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

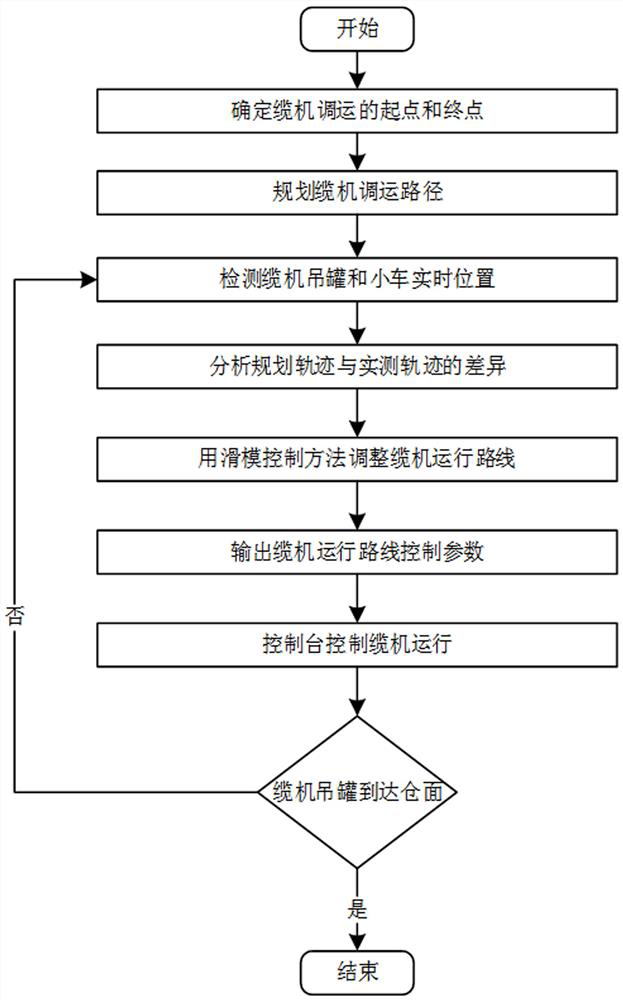

[0045] Such as figure 1 Among them, a concrete dam cable machine entry trajectory planning and control method, including the following steps:

[0046] S1. Determine the starting point and end point of the cable machine according to the location of concrete pouring and the location of the material supply point. The starting point is the installation point of the cable machine A(x a ,y a ,z z ); the end point is the cable machine unloading position B(x b ,y b ,z b );

[0047] S2, planning the path of cable machine transfer and transportation into the warehouse:

[0048] S 1 = S 1 (x 1 ,y 1 ,z 1 );

[0049] S3, install a positioning system and a wireless transceiver device on the cable crane tank; the positioning system locates the real-time coordinates (x, y, z) of the cable crane tank, and transmits them to the cable machine control terminal through the wireless transceiver device at regular intervals t The coordinate value of the hanging tank of the cable machine,...

Embodiment 2

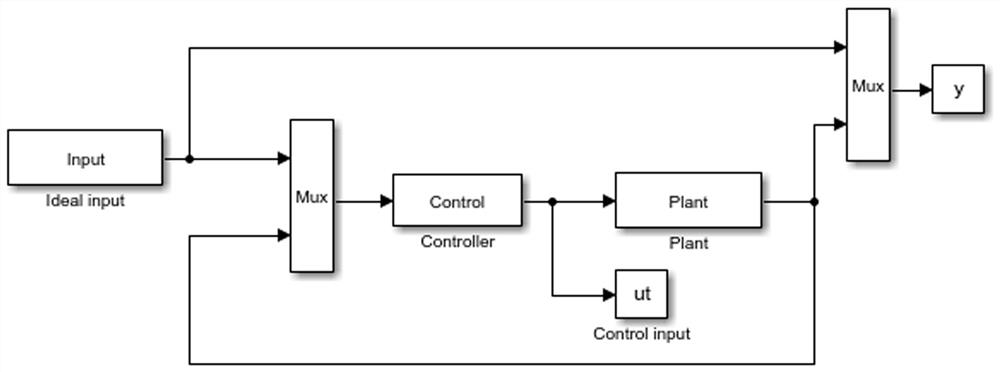

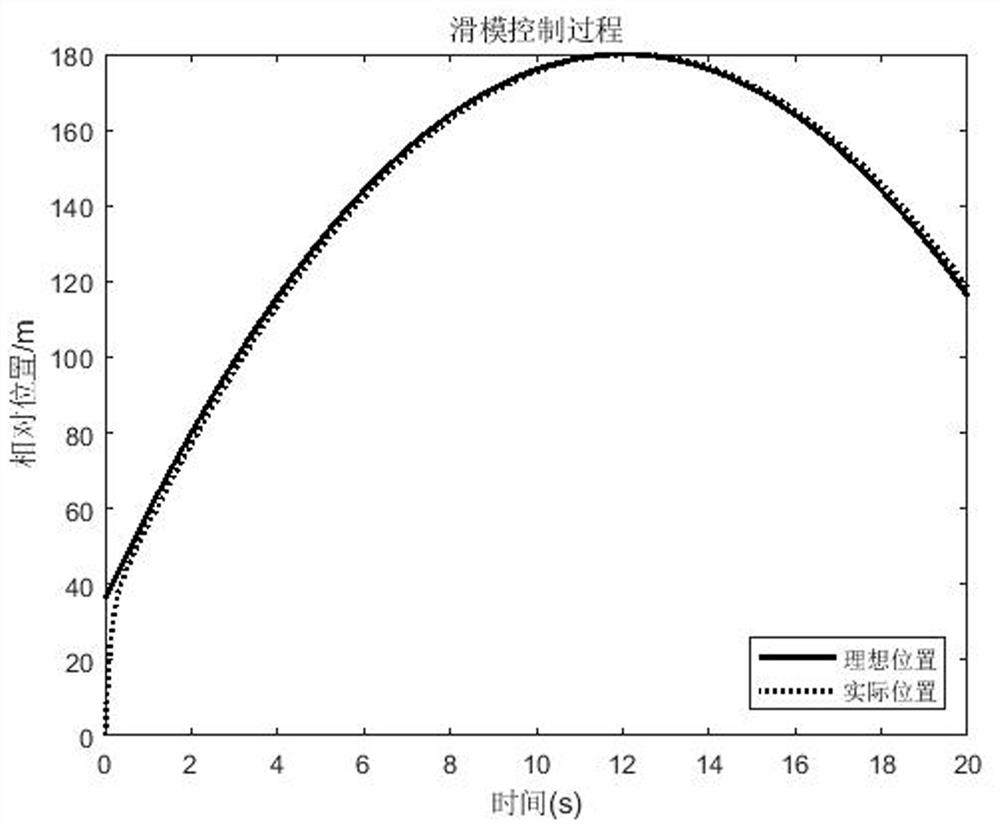

[0078] Such as Figure 2 ~ Figure 4 In this paper, the above-mentioned cable machine path control process is simplified as a two-dimensional plane control problem, assuming that the cable machine moves on the two-dimensional plane XOY, the starting point of the movement is A(0,40), the end point is B(20,120), the cable machine motion The highest point is H(12,180), and the trajectory line of the cable machine entering the warehouse is planned based on this, and the trajectory line of the cable machine entering the warehouse is regarded as a function of time t. The planning results are as follows:

[0079] S 1 =-(t-12) 2 +180;

[0080] where S 1 That is the ideal trajectory of the cable machine.

[0081] Suppose the actual running track equation of the cable machine is S=S(t), and the actual running track of the cable machine is also a function of time, then the position tracking error is: e(t)=S(t)-S 1 (t)=S(t)+(t-12) 2 -180; speed tracking error is:

[0082] The slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com