Semiconductor structure and manufacturing and thinning method thereof

A semiconductor and substrate technology, which is applied in the fields of thinning, semiconductor structures and their fabrication, and can solve problems such as low efficiency and poor chip quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0039] As mentioned in the background technology, most of the existing chip thinning methods are mechanical grinding, that is, using a thinning machine or a polishing machine for thinning. The thinning thickness is greatly restricted by the equipment, and, due to the , The transistor circuit and wiring are more complex, resulting in uneven stress, so after mechanical grinding, the obtained chips are of poor quality. At the same time, the efficiency of mechanical grinding is also low.

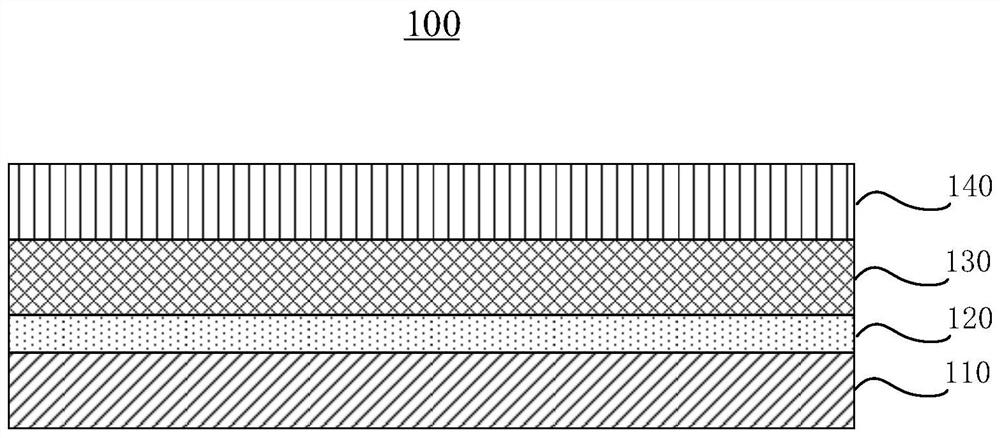

[0040] In view of this, in order to solve the above problems, the present application provides a semiconductor structure, by setting a thinned functional layer in the semiconductor structure, and the etching rate of the substrate and the target etching solution is greater than or equal to the thinned functional layer 2 times the etching rate of the target etching solution. So that when the semiconductor structure is placed in the target etching solution, after the substrate and the buffer layer...

no. 2 example

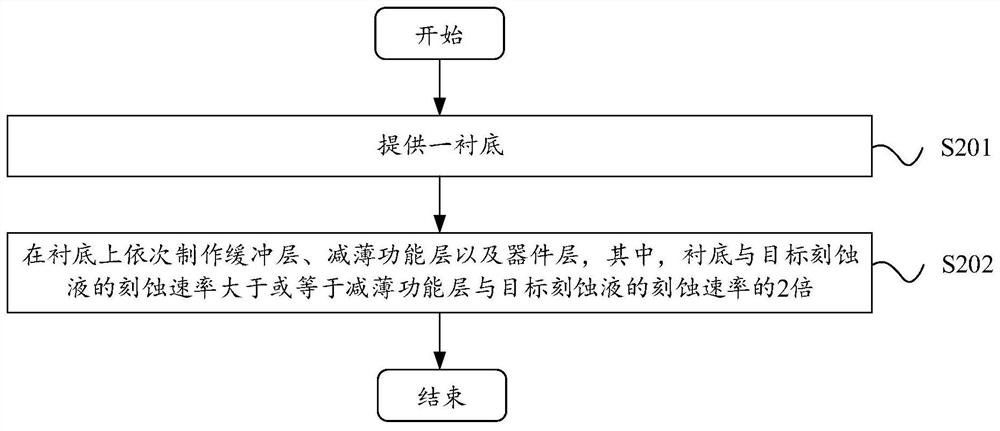

[0055] see figure 2 , the embodiment of the present application also provides a semiconductor structure manufacturing method, the semiconductor structure manufacturing method can manufacture the semiconductor structure described in the first embodiment, the method includes:

[0056] S201, providing a substrate.

[0057] S202, sequentially fabricating a buffer layer, a thinned functional layer and a device layer on the substrate, wherein the etching rate of the substrate and the target etching solution is greater than or equal to 2 of the etching rate of the thinned functional layer and the target etching solution times.

[0058] Wherein, the material of the thinned functional layer and the substrate can be any one of the materials described in the first embodiment, which is not limited in this application.

[0059] In addition, in this application, there is no limitation on the production process of the thinned functional layer, which can be produced by epitaxial process or...

no. 3 example

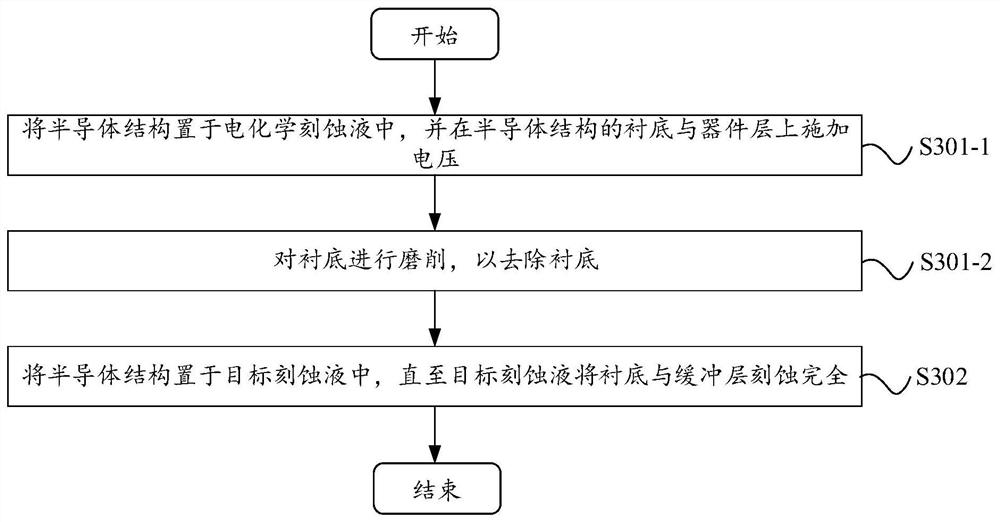

[0061] see image 3 , the embodiment of the present application also provides a semiconductor structure thinning method, which can be used to thin the semiconductor structure described in the first embodiment. As an optional implementation, the method includes:

[0062] S302, placing the semiconductor structure in a target etchant until the target etchant completely etches the substrate and the buffer layer.

[0063] That is, in this application, chemical etching is used to thin the semiconductor structure, and the material of the target etching solution has been described in detail in the first embodiment, and will not be repeated here.

[0064] It can be understood that in fabricating the semiconductor structure, since the front and side surfaces of the device layer are encapsulated, it is possible to isolate the target etchant from etching the device material. When the semiconductor structure is placed in the target etchant, the target etchant can etch away the sinker and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com