Conductive bonding sheet

A conductive, bonding sheet technology, applied in the direction of conductive adhesives, adhesive types, conductive materials dispersed in non-conductive inorganic materials, etc. Weak strength and other problems, to achieve the effect of good temporary fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2、 comparative example 1

[0094] 240 parts by mass of a mixed solvent of toluene and methyl ethyl ketone (volume ratio 40:60) and mix the ingredients listed in the compounding table to prepare the adhesive compositions of Examples and Comparative Examples (solid content: 42% by mass) . The details of each ingredient used are as follows.

[0095] Urethane-modified polyester resin: Toyobo Co., Ltd., trade name "VYLON UR-3600"

[0096] Organophosphorus flame retardant: manufactured by Clariant Chemical Co., Ltd., trade name "Exolit OP935"

[0097] Epoxy resin: manufactured by Nippon Kayaku Co., Ltd., trade name "NC-2000-L"

[0098] Epoxy-based plasticizer: manufactured by ADEKA (stock), trade name "ADK Cizer O130P".

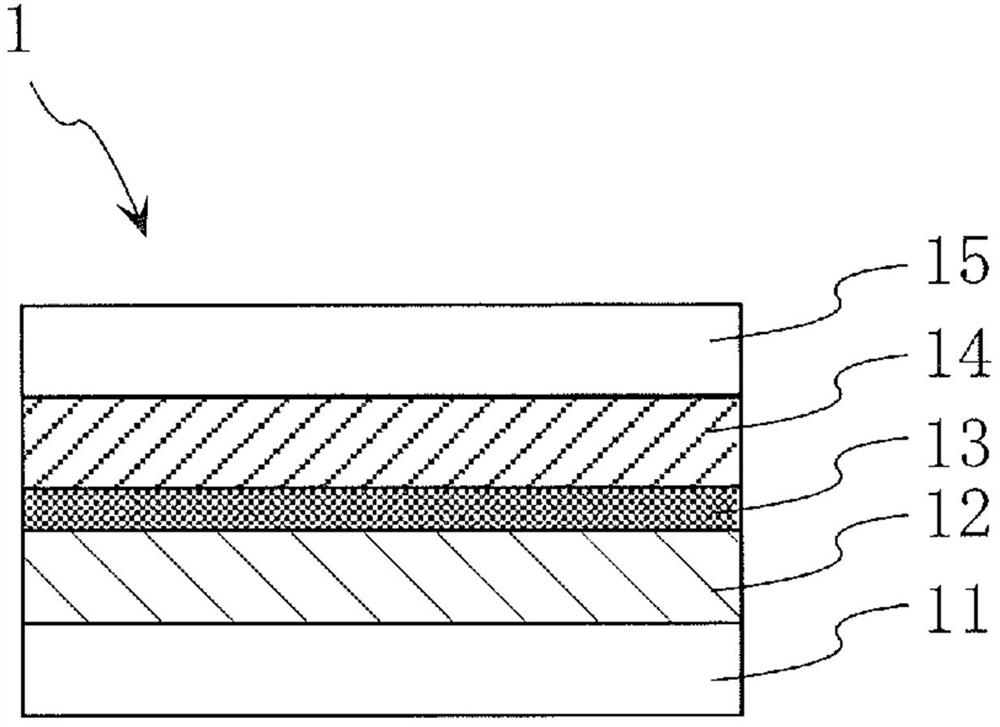

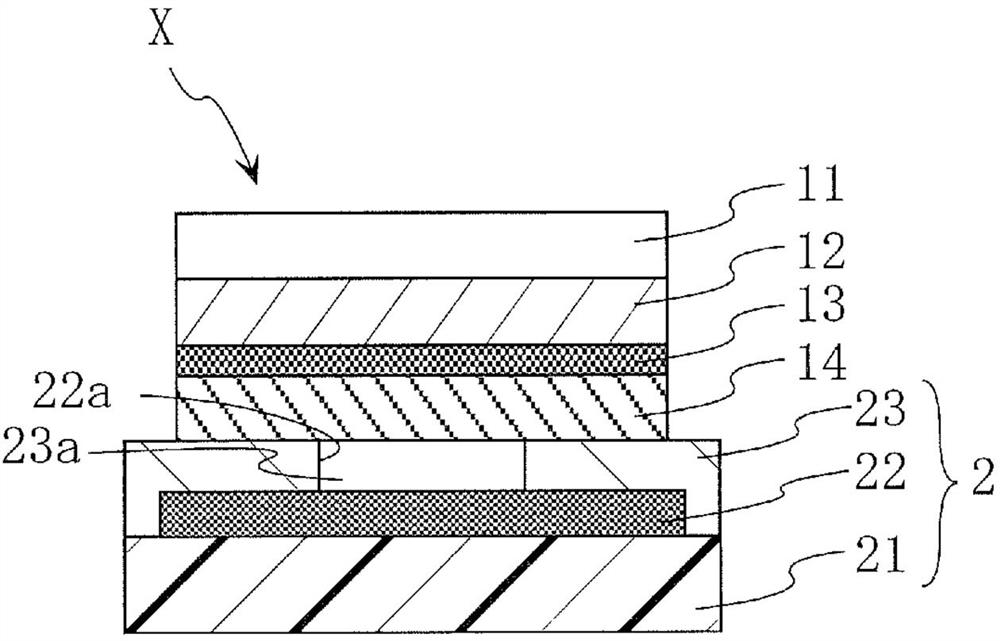

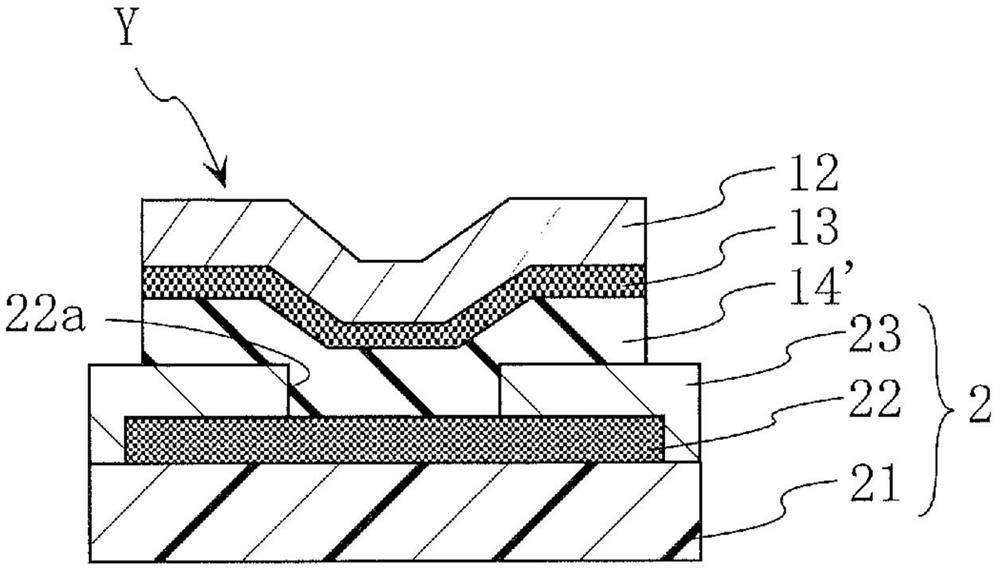

[0099] A protective layer with a thickness of 5 μm was formed by applying a resin composition for a protective layer on the surface of a PET film (thickness 25 μm) whose surface was treated with a release agent using a wire bar and heating and drying. Next, the produced copper foil with ...

reference example 1

[0102] A commercially available shielding film (manufactured by Takuta Cable Co., Ltd., trade name "PC6000U1") was used.

[0103] (evaluate)

[0104] The conductive bonding sheets of the respective shielding films obtained in Examples, Comparative Examples, and Reference Examples were evaluated as follows. The evaluation results are shown in the table.

[0105] (1) Surface state

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com