A high-pressure flushing fish descaling machine

A high-pressure washing and fish cutting technology, which is applied in fish cleaning/descaling, processing fish, slaughtering, etc., can solve the problems of general descaling effect, heavy machinery, complex structure, etc., to ensure descaling effect, low cost, and optimization. The effect of the mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

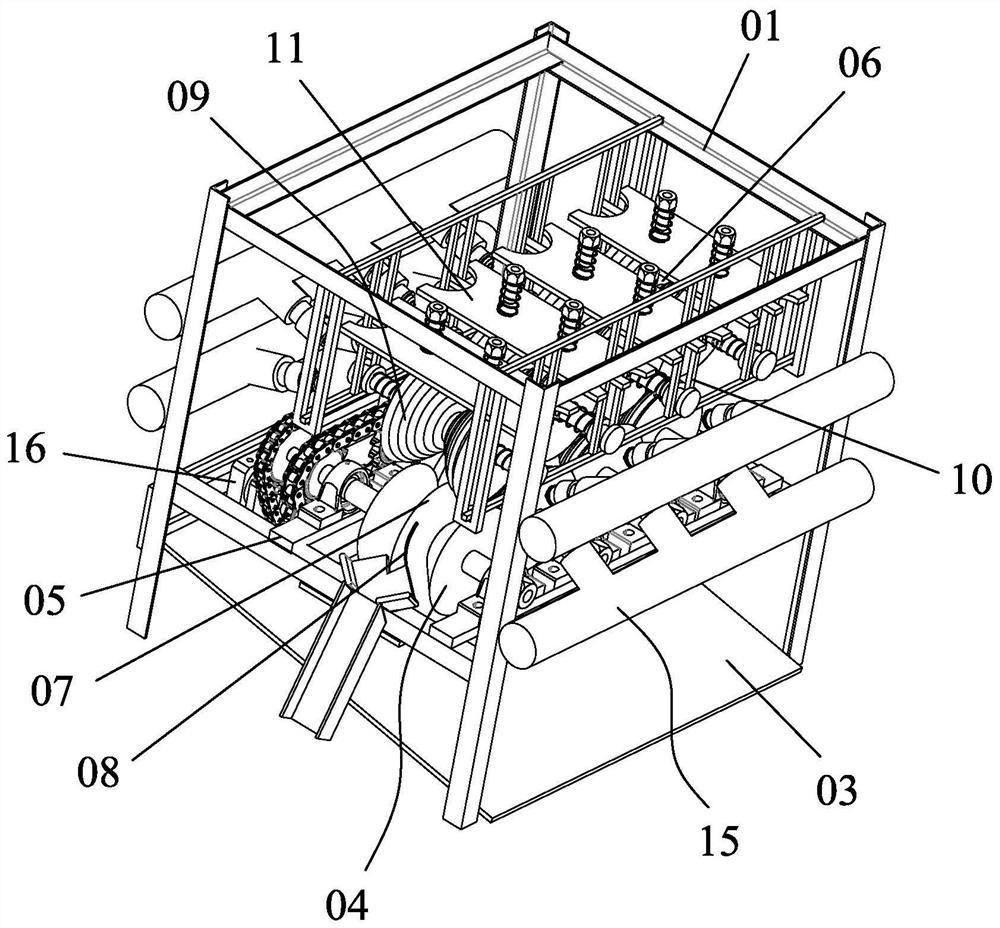

[0026] Further description will be given below in conjunction with the embodiments shown in the accompanying drawings.

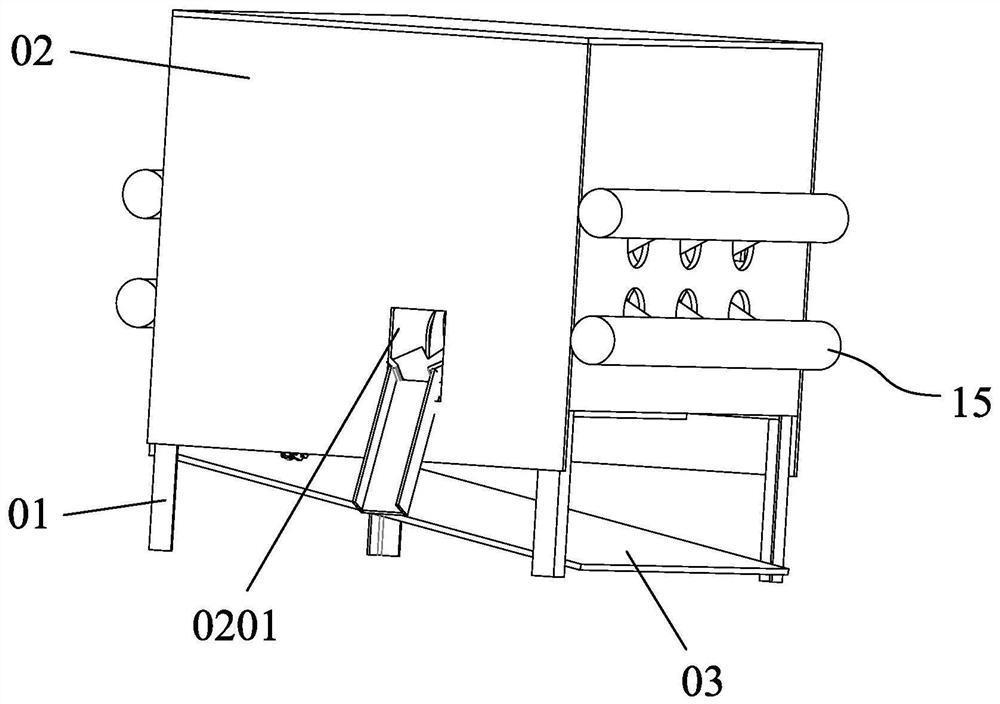

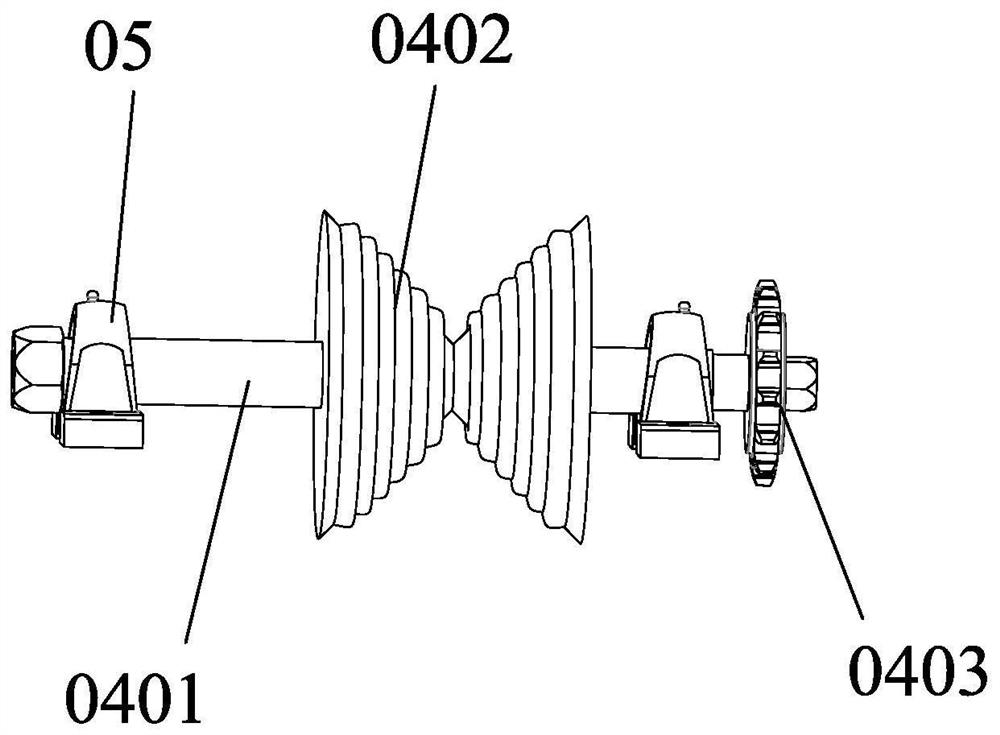

[0027] Such as figure 1 , figure 2 The high-pressure flushing type descaling fish dissection machine includes a frame 01, a conveying assembly, a high-pressure water gun, a driving assembly, a clamping assembly, an adjustment assembly, a laparotomy spreader 07 and a laparotomy cleaner 08.

[0028] Such as figure 1 As shown, the four sides of the frame and the upper and lower sides of the frame are provided with cover plates 02, so that the internal structure of the descaling fish splitter is closed, and the cover plates on the left and right sides are respectively pre-installed. There is a through hole for the high-pressure water gun to pass through, a fish inlet is reserved on the rear cover, a fish outlet 0201 is reserved on the front cover, and leak holes are uniformly arranged on the lower cover (Fig. The middle and lower side cover plate is not show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com