Combined tool for skin stretch forming and numerical control milling and using method thereof

A technology of CNC milling and milling, which is used in manufacturing tools, other manufacturing equipment/tools, etc., to achieve the effect of ensuring accuracy, ensuring matrix strength, and preventing tremors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

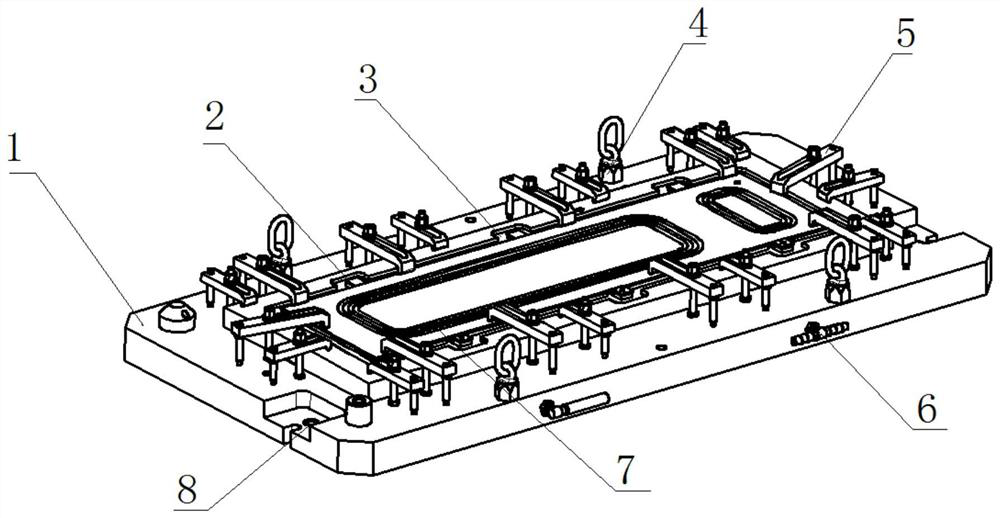

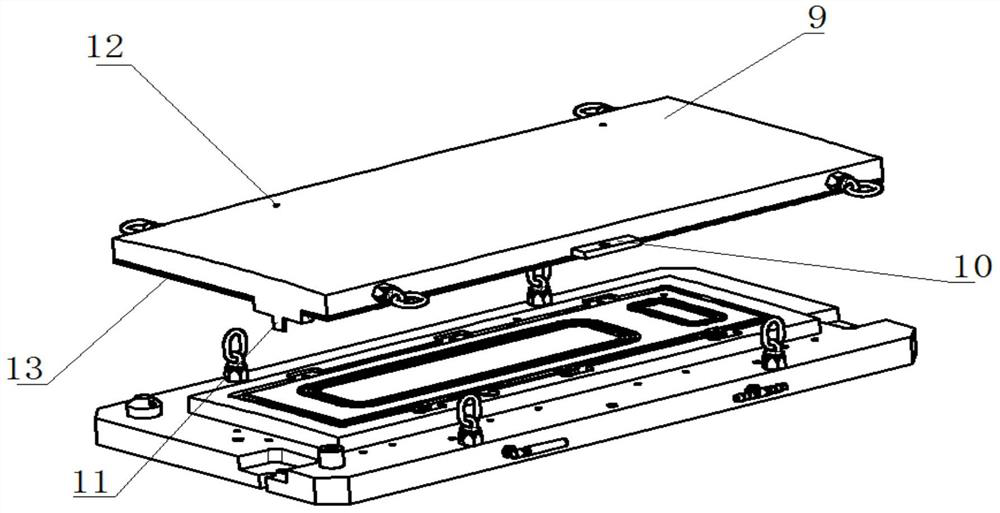

[0019] Such as Figure 1-2 As shown, a combined tooling for skin drawing and CNC milling, including drawing half mold 9 and milling half mold 1, lifting ring 4, part pressure plate 5, vacuum hose 6, rubber pad 13, drawing half mold The upper surface of the die 9 is the shape of the part and its extension surface. The two ends of the length direction are provided with pull-shaped positioning holes 12. There is a guide column 11, a positioning boss 10 is arranged in the middle of the side in the length direction, the center of the milling half mold 1 is a boss shape, the surface shape of the boss is the shape of the part and its extension, and a milling groove 3 is formed at the edge of the shape of the part , the inner side of the milling groove 3 is provided with an air extraction hole 7, the boss is surrounded by a part pressure plate 5, and the milling half-mold 1 is provided with a milling positioning hole 2 corresponding to the position of the pull-shaped positioning hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com