Polyurethane superfine fiber synthetic leather with multicolor three-dimensional effect

A technology of ultra-fine fibers and three-dimensional effects, which is applied in textiles and papermaking, fabric surface trimming, thorn patterns, etc., can solve the problems of changing the texture and feel of synthetic leather, hardening of synthetic leather, and the inability to accurately control the depth of three-dimensional skin patterns. Achieve high decomposition temperature and controllable precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

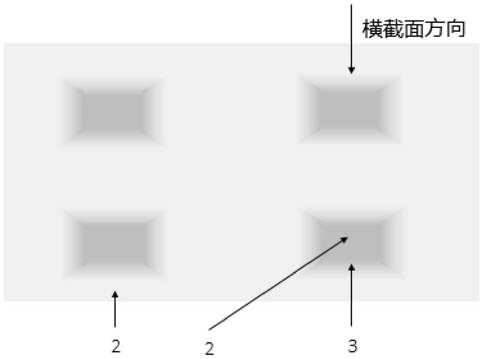

[0030] Such as figure 1 and 4 As shown, a polyurethane microfiber synthetic leather with multi-color three-dimensional effect includes a polyurethane microfiber base cloth layer 1 (nylon nonwoven fabric impregnated with polyurethane) and a polyurethane coating bonded to one side of the base cloth layer 1. Layer 2 (the material is a mixture of water-based polyurethane and DuPont R103), has a trapezoidal depression 3 with a three-dimensional structure in the direction from the outside of the polyurethane coating 2 to the base fabric layer 1, and the density of the base fabric layer depression is the same as the density of the surrounding base fabric layer The same, the density of the polyurethane coating depression is the same as that of the surrounding polyurethane coating; the thickness of the base cloth layer is 0.2mm, and the thickness of the polyurethane coating is 0.01mm; the depression is composed of polyurethane microfibers with multi-color three-dimensional effect The...

Embodiment 2

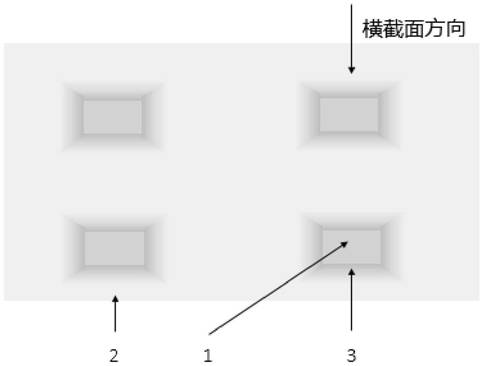

[0032]A kind of polyurethane microfiber synthetic leather with multi-color three-dimensional effect, including polyurethane microfiber base cloth layer (nylon nonwoven fabric impregnated with polyurethane) and polyurethane coating bonded on one side of the base cloth layer (material is water-based The mixture of polyurethane and Cabot carbon black bp2000) has a trapezoidal depression with a three-dimensional structure in the direction from the outside of the polyurethane coating to the base fabric layer. The density of the base fabric depression is the same as that of the surrounding base fabric layer. The polyurethane coating The density of the depression is the same as that of the surrounding polyurethane coating; the thickness of the base fabric layer is 0.2mm, and the thickness of the polyurethane coating is 2mm; the depression is a multi-color three-dimensional pattern composed of polyurethane microfiber synthetic leather with multi-color three-dimensional effect The minim...

Embodiment 3

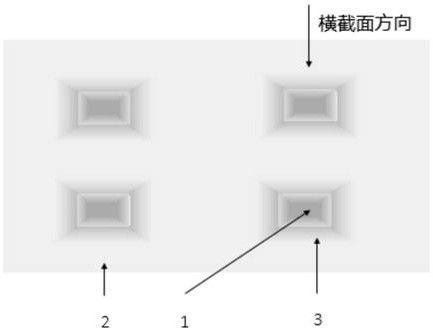

[0034] Such as figure 2 and 5 As shown, a polyurethane microfiber synthetic leather with multi-color three-dimensional effect includes a polyurethane microfiber base cloth layer 1 (nylon nonwoven fabric impregnated with polyurethane) and a polyurethane coating bonded to one side of the base cloth layer 1. Layer 2 (the material is a mixture of solvent-based polyurethane and BASF Yellow K 1500FP), has a trapezoidal depression 3 with a three-dimensional structure in the direction from the outside of the polyurethane coating 2 to the base fabric layer 1, and the density of the base fabric layer depression is the same as that of the surrounding base fabric. The density of the layers is the same, and the density of the polyurethane coating depression is the same as that of the surrounding polyurethane coating; the base cloth layer and the polyurethane coating have different hues, and the color difference ΔE is 0.5; the thickness of the base cloth layer is 4mm, and the polyurethane ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com