Coal mine working face tunneling crushed coal conveying equipment

A technology of conveying equipment and working face, which is applied in the direction of propulsion, driving device, earthwork drilling and mining, etc. It can solve the problems of a large amount of coal dust, which is not conducive to the steady development of mining enterprises, and threatens the personal safety of underground workers in coal mines. It is easy to use and simple in structure. , Reduce the effect of worker safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

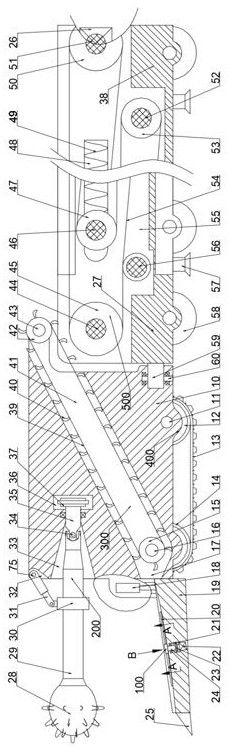

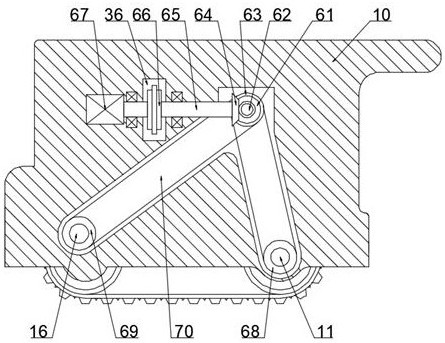

[0018] Combine below Figure 1-4 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

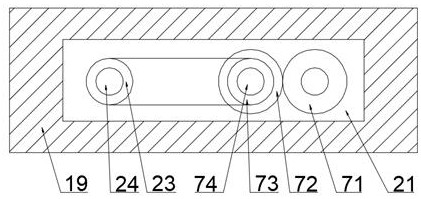

[0019] A coal mining face excavation crushed coal conveying equipment described in conjunction with accompanying drawings 1-4, includes a fuselage 10, and a lifting chamber 41 with an opening to the right and extending left and right is arranged in the fuselage 10, and the lifting chamber 41 is directed to The left connection is provided with a feed chamber 17 with an opening to the left. The left end wall of the fuselage 10 slides up and down to be provided with a shovel plate 19. The lower end is fixedly connected with the shoveling plate 19, and the left end of the shoveling plate 19 is fixedly provided with a shoveling plate 25, and the shoveling plate 19 is fixedly provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com