Detection device and method

A detection device and detection method technology, applied in the detection field, can solve the problems of long feedback time of detection results and low detection frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Detection of miscellaneous oil content in fluids (eg, cleaning agents).

[0034] During the operation of the cleaning machine, various impurities will be mixed into the cleaning agent, and these impurities may include emulsified miscellaneous oil and / or water-soluble impurities. The inventor found through research that the most important influence on the cleaning effect is the content of miscellaneous oils. In addition, due to the complex composition of water-soluble impurities, the influence of different types of substances on the density is not the same, and the data obtained by only using the density meter to test the stock solution will have a large deviation.

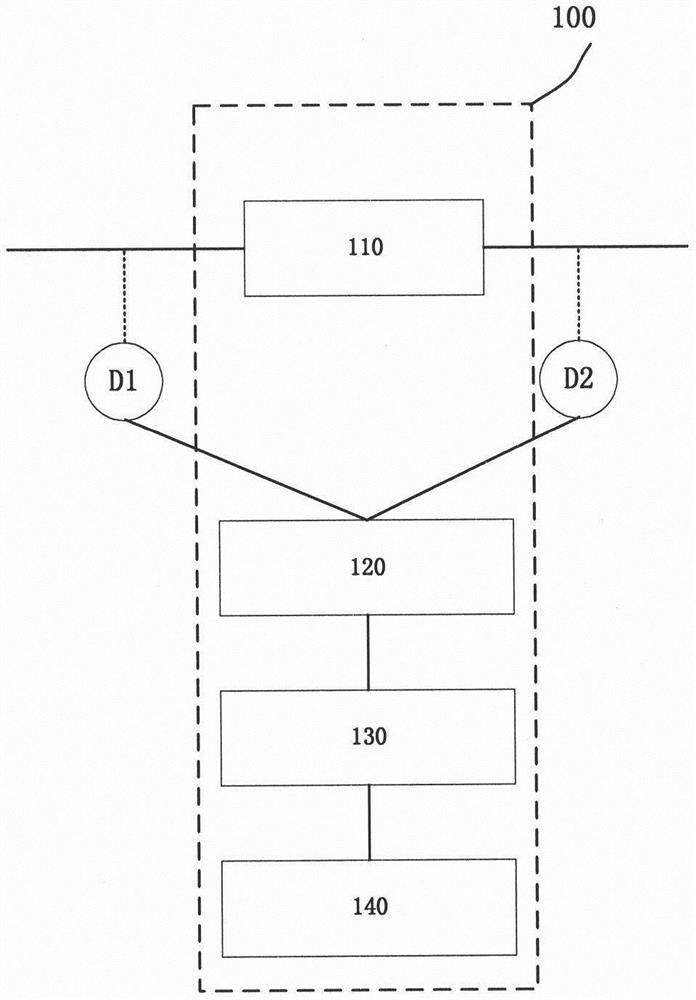

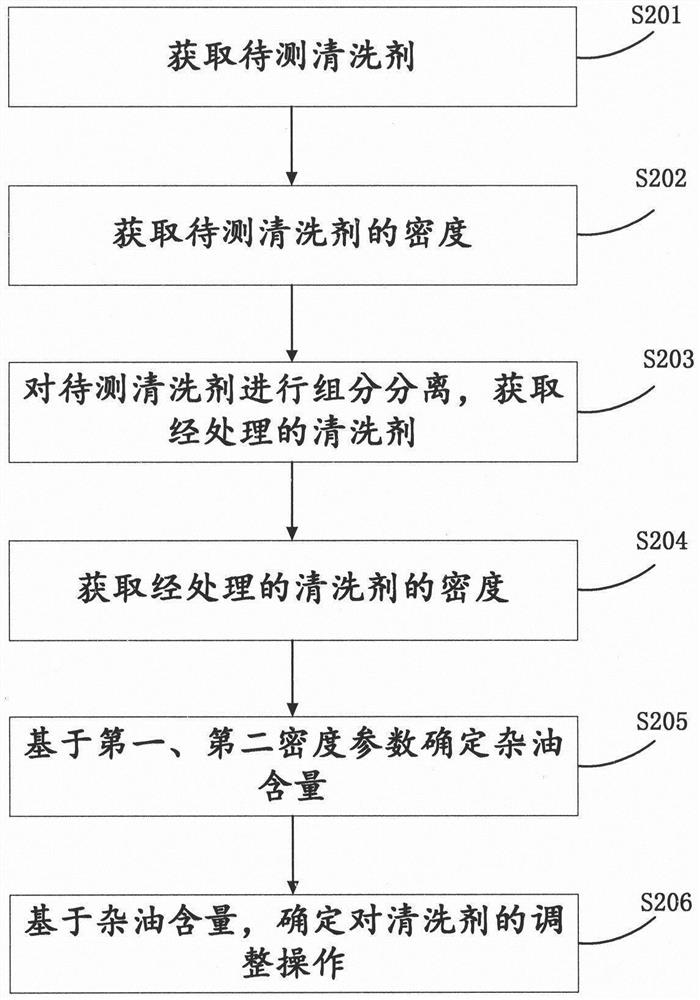

[0035] see also figure 1 , 2 ,in, figure 2 It is a flow chart of detecting miscellaneous oil according to an embodiment of the present invention.

[0036] Step S201: Obtain the cleaning agent to be tested.

[0037] In this step, the cleaning agent in use can be obtained as the cleaning agent...

Embodiment 2

[0050] Example 2: Detecting the content of solid particles and emulsified oil in the fluid.

[0051] Solid particles have the characteristics of large size and solid state, and emulsified oil has the characteristics of microscopic liquid and insoluble in water. Therefore, in this embodiment, the solid particles are filtered with the first filtration precision, thereby reducing the number of solid particles in the fluid; the emulsified oil is filtered with the second filtration precision, thereby reducing the content of the emulsified oil in the fluid. Due to the difference in the characteristics of solid particles and emulsified oil, when solid particles and emulsified oil exist in the stock solution at the same time, it is necessary to remove the solid particles first and then remove the emulsified oil.

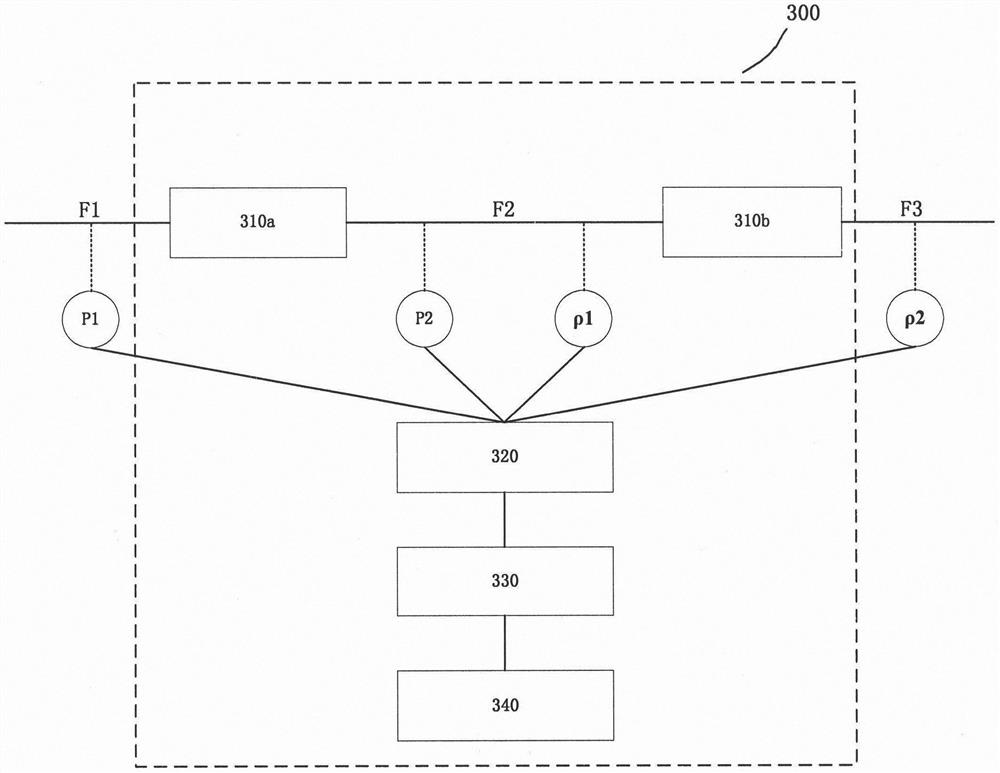

[0052] Figure 3a It is a structural diagram of a detection apparatus according to another embodiment.

[0053] The detection device 300 includes separation modules 310 a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com