Potassium magnesium sulphate composite crystal slow-release salt product for improving milk yield of dairy cows and preparation method thereof

A technology of potassium magnesium sulfate and composite crystallization, applied in animal feed, additional food elements, animal feed, etc., can solve the problems of low bioavailability, inconsistent demand, unbalanced ratio, etc., and achieve high bioavailability and small gastrointestinal irritation , long-term effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A potassium-magnesium sulfate composite crystalline slow-release salt product, and its preparation method is as follows:

[0021] Potassium Magnesium Sulfate Crystalline Salt 55%

[0022] Bentonite 20%

[0023] Plant extracts 25%;

[0024] Stirring and mixing the potassium magnesium sulfate composite crystal salt with the carrier, then adding the carrier, stirring and mixing evenly, finally adding the plant extract, stirring and mixing for 5 hours, and finally drying to obtain the potassium magnesium sulfate composite crystal slow-release salt product.

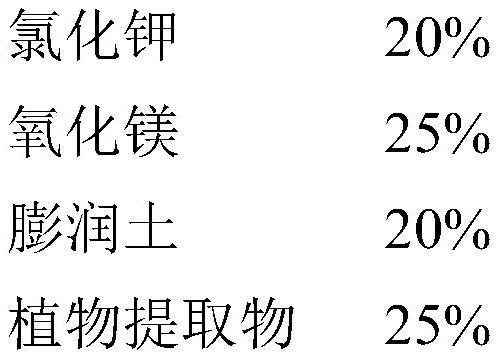

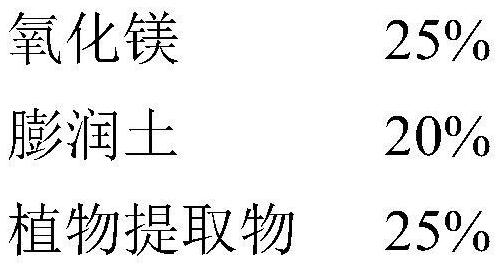

Embodiment 2

[0026] A potassium-magnesium sulfate composite crystalline slow-release salt product, and its preparation method is as follows:

[0027] Potassium Magnesium Sulfate Crystalline Salt 60%

[0028] Kaolin 20%

[0029] Plant extracts 20%;

[0030] Stirring and mixing potassium magnesium sulfate composite crystal salt and carrier, then adding carrier, stirring and mixing, finally adding plant extract, stirring and mixing for 8 hours, and finally drying to obtain the potassium magnesium sulfate composite crystal slow-release salt product.

Embodiment 3

[0032] A potassium-magnesium sulfate composite crystalline slow-release salt product, and its preparation method is as follows:

[0033] Potassium Magnesium Sulfate Crystalline Salt 50%

[0034] Montmorillonite 30%

[0035] Plant extracts 20%;

[0036] Stirring and mixing the potassium magnesium sulfate composite crystal salt and the carrier, then adding the carrier, stirring and mixing, finally adding the plant extract, stirring and mixing for 10 hours, and finally drying to obtain the potassium magnesium sulfate composite crystal slow-release salt product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com