Efficient syringe machining device for medical waste recovery

A processing device and a technology for medical waste, applied in the field of high-efficiency processing devices for syringes for recycling medical wastes, can solve the problems of inability to sterilize the syringe powder, scratches on the hands of nurses, and inability to stir powders, etc., so as to avoid hand scratches. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

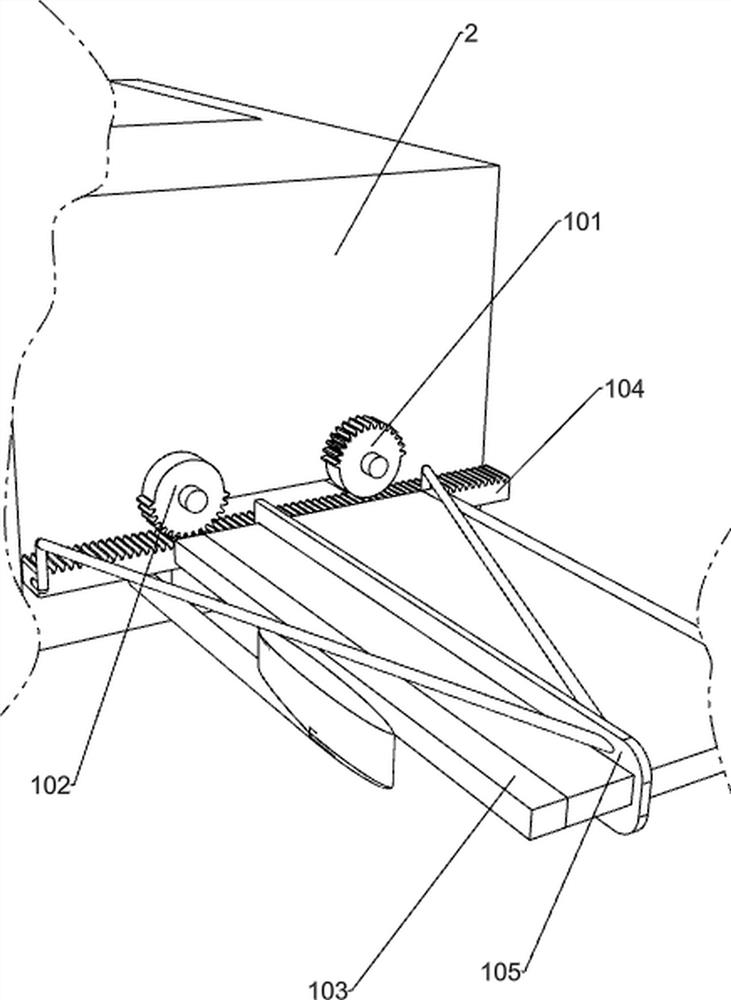

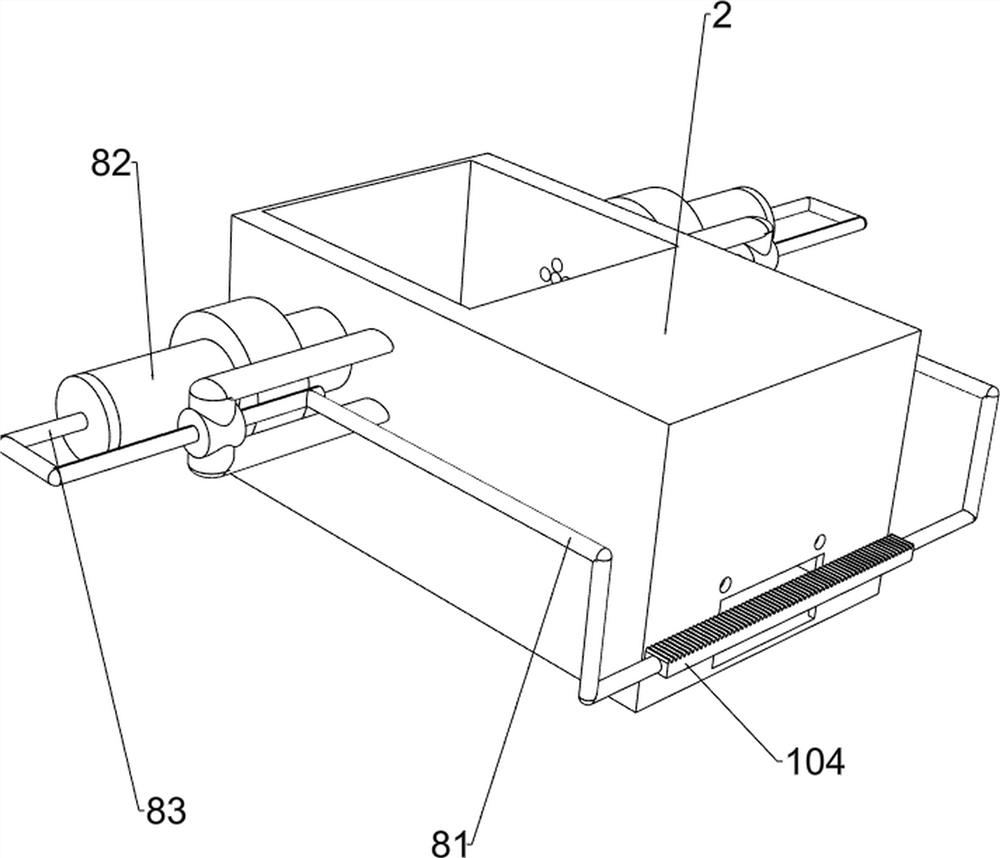

[0070] A high-efficiency processing device for syringes for medical waste recycling, such as figure 1 As shown, it includes a support frame 1, a limiting frame 2, a crushing mechanism 3, a secondary crushing mechanism 4, a third-stage crushing mechanism 5 and a fourth-stage crushing mechanism 6. The rear side of the support frame 1 is provided with a limiting frame 2, and the limiting frame There is a crushing mechanism 3 rotating between the upper parts of the limit frame 2, and a secondary crushing mechanism 4 is installed between the upper parts of the limit frame 2. Mechanism 5, secondary crushing mechanism 4 cooperates with tertiary crushing mechanism 5, and four-stage crushing mechanism 6 is rotationally installed between the limit frame 2 bottoms, and tertiary crushing mechanism 5 cooperates with fourth-stage crushing mechanism 6.

[0071] When the medical personnel need to crush the syringe, the medical personnel first need to pour an appropriate amount of the syringe ...

Embodiment 2

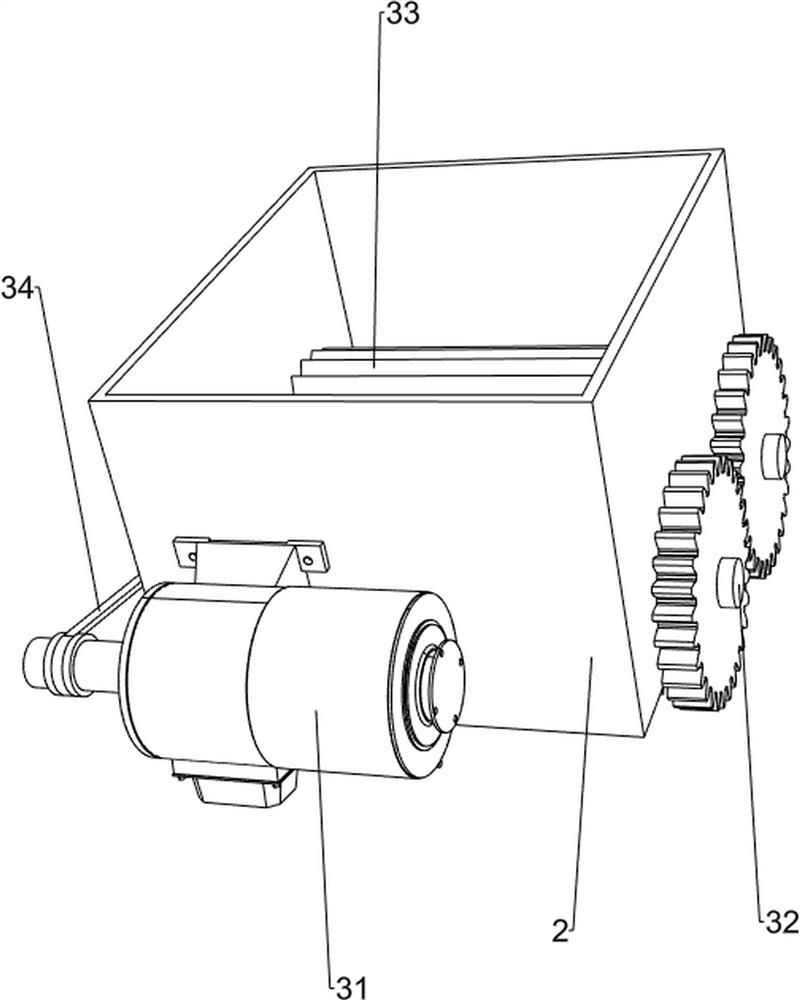

[0073] In a preferred embodiment of the present invention, as figure 2 As shown, the crushing mechanism 3 includes a motor 31, a first crushing column with gears 32, a second crushing column with gears 33 and a first pulley assembly 34, and the upper part on the right side of the limit frame 2 is fixed with a motor 31 by bolts. The upper part of the frame 2 is rotatably provided with a first crushing column with gears 32 and a second crushing column with gears 33, the first crushing column with gears 32 is in contact with the second crushing column with gears 33, and the front end of the output shaft of the motor 31 is in contact with the A first pulley assembly 34 is connected between the front ends of the first geared crushing column 32 .

[0074] The medical staff first needs to pour an appropriate amount of syringe into the limit frame 2. When the syringe is located in the limit frame 2, the medical staff can start the motor 31 to rotate, and the output shaft of the motor...

Embodiment 3

[0076] In a preferred embodiment of the present invention, as figure 1 with Figure 3-Figure 12 As shown, the secondary crushing mechanism 4 includes a first geared crushing column 41, a second geared crushing column 42 and a second pulley assembly 43, and a first geared crushing column 43 is rotated between the top of the limit frame 2. The crushing column 41 and the second crushing column 42 with gears, the first crushing column 41 with gears is in contact with the second crushing column 42 with gears, the front end of the second crushing column 42 with gears is in contact with the second crushing column 33 with gears A second pulley assembly 43 is connected between the front ends.

[0077] The injector between the rotation of the first geared crushing column 32 and the lower part of the second geared crushing column 33 will fall between the first geared crushing column 41 and the second geared crushing column 42, and the second geared crushing column 42 will be broken. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com