Automatic weld joint tracking method based on deep neural network

A deep neural network and automatic tracking technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve problems such as image noise pollution, inaccurate welding seam tracking, welding deviation, etc., to improve adaptability and robustness , good tracking effect, and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and through specific implementation methods.

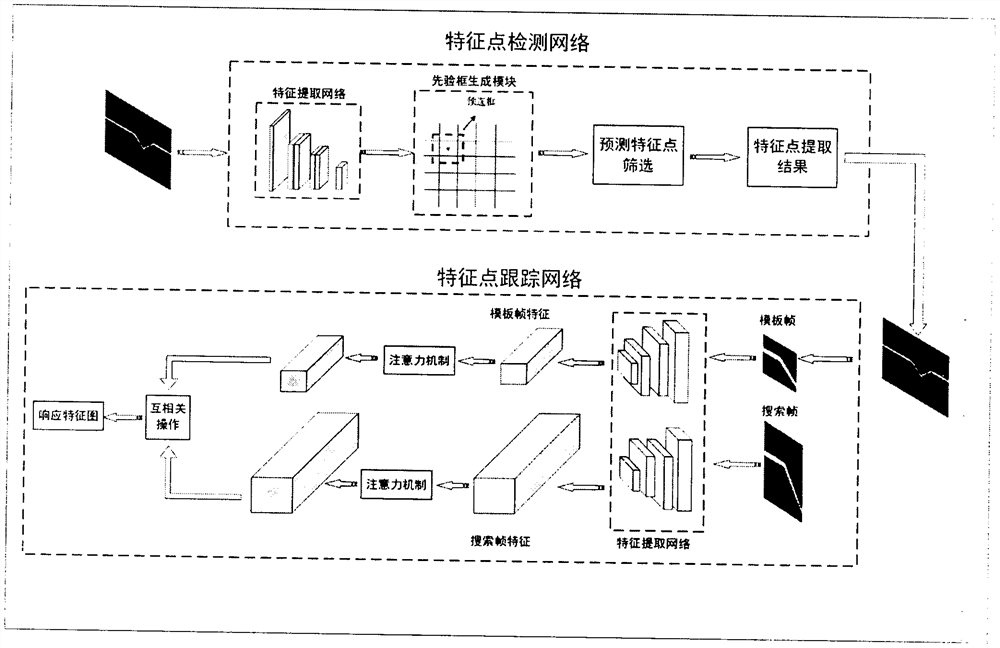

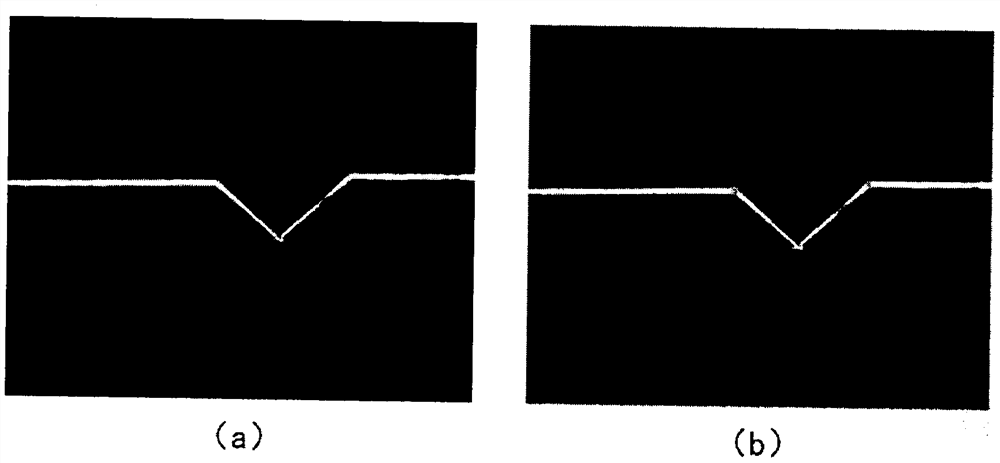

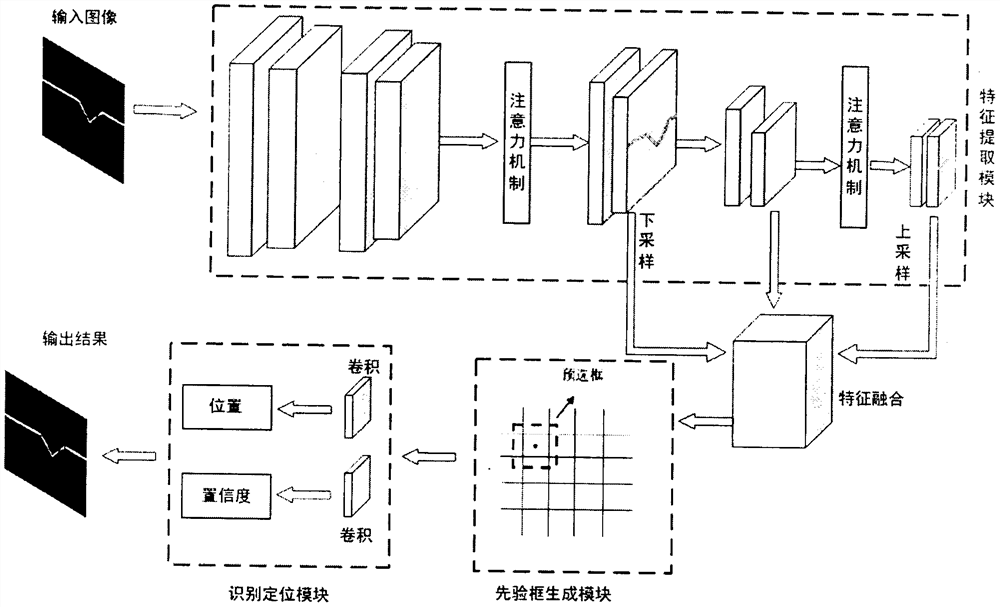

[0019] The automatic seam tracking method based on deep neural network includes seam feature point detection network and seam feature point tracking network. The specific network implementation diagram is given by figure 1 give. The weld feature point detection network is mainly composed of a feature extraction module, an attention mechanism module, a priori frame generation module, and a recognition and positioning module. The feature extraction module uses the deep neural network to extract the features of the weld image. The attention mechanism module is to make the network put more attention resources near the laser stripes and weld feature points. The a priori frame generation module allows the network to transfer from global detection feature points to local detection, reducing the difficulty of extracting weld fea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com