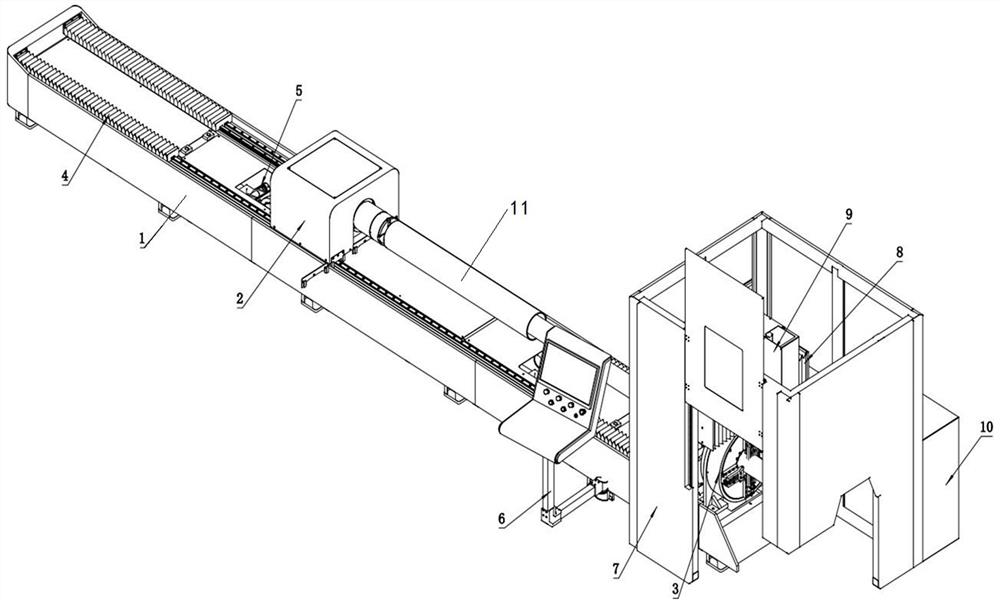

Pipe laser cutting machine

A laser cutting machine and pipe technology, which is applied to laser welding equipment, welding/cutting auxiliary equipment, tubular objects, etc., can solve problems such as increasing costs and reducing processing output, so as to improve efficiency, reduce labor, and shorten inspections. The effect of maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further explained below in conjunction with the accompanying drawings.

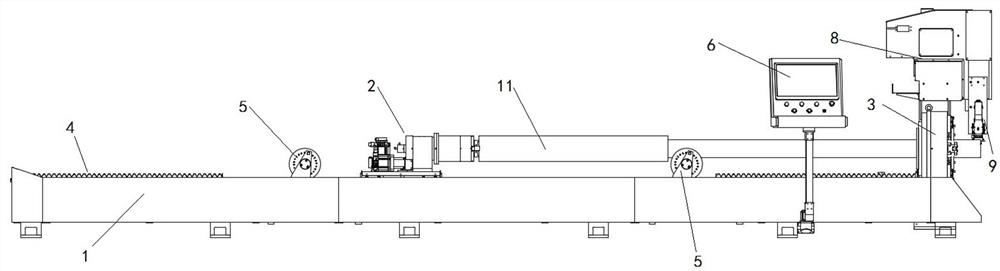

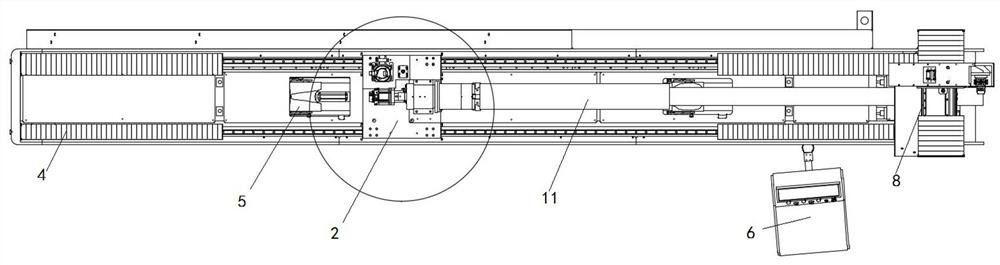

[0026] A pipe laser cutting machine, comprising a fuselage 1 and a head 9, the head 9 includes a laser head 91, a vertically slidable vertical plate 93 and a laterally slidable horizontal plate 97, the laser head 91 is installed on The lower plate surface of the mounting plate 92, the upper plate surface of the mounting plate 92 is vertically connected to the vertical plate 93;

[0027] The horizontal plate 97 is provided with a horizontal axis motor 95, the axial direction of the horizontal axis motor 95 is vertically arranged, and the horizontal plate 97 is slidably arranged on the crossbeam 8; A T-shaped vertical beam 96 , the vertical plate 93 is driven by a lead screw 94 and slidably arranged on the vertical beam 96 . First, the lateral movement and longitudinal movement of the machine head 9 are respectively driven by the horizontal axis motor 95 and the lead sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com