Flexible actuator driven by chemical energy release reaction

A technology of energy release reaction and actuator, applied in the field of robotics, can solve problems such as fast motion performance and load capacity defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

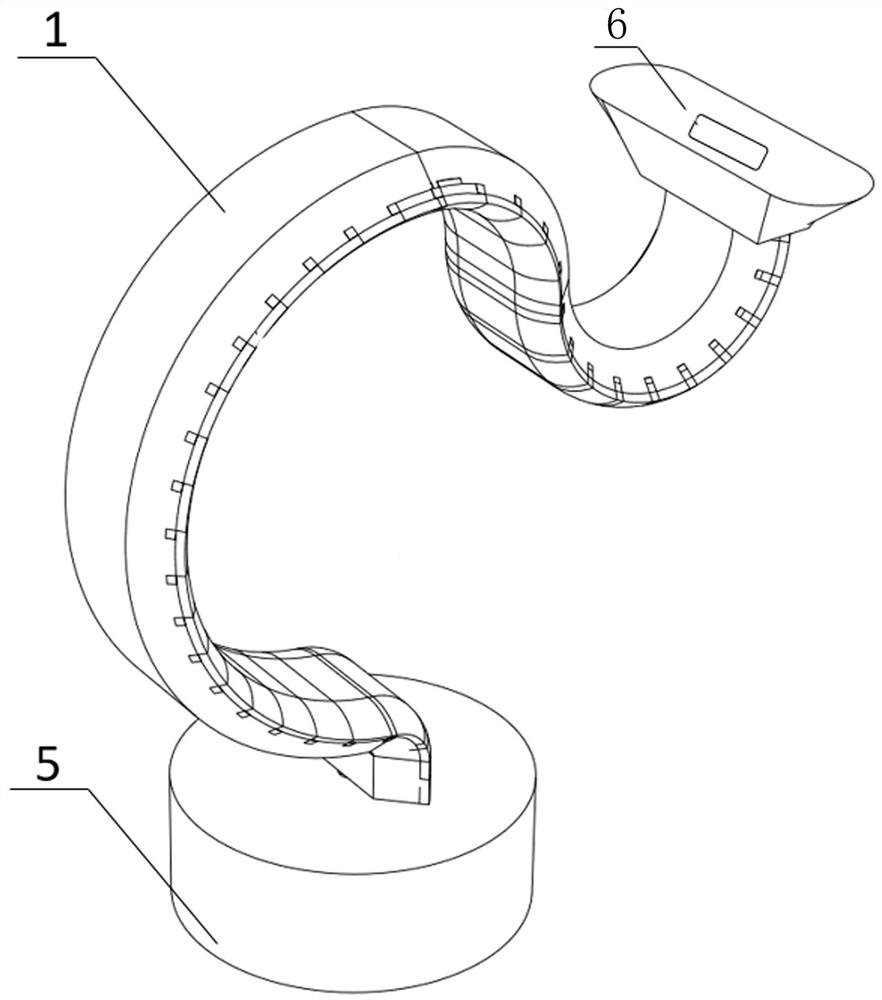

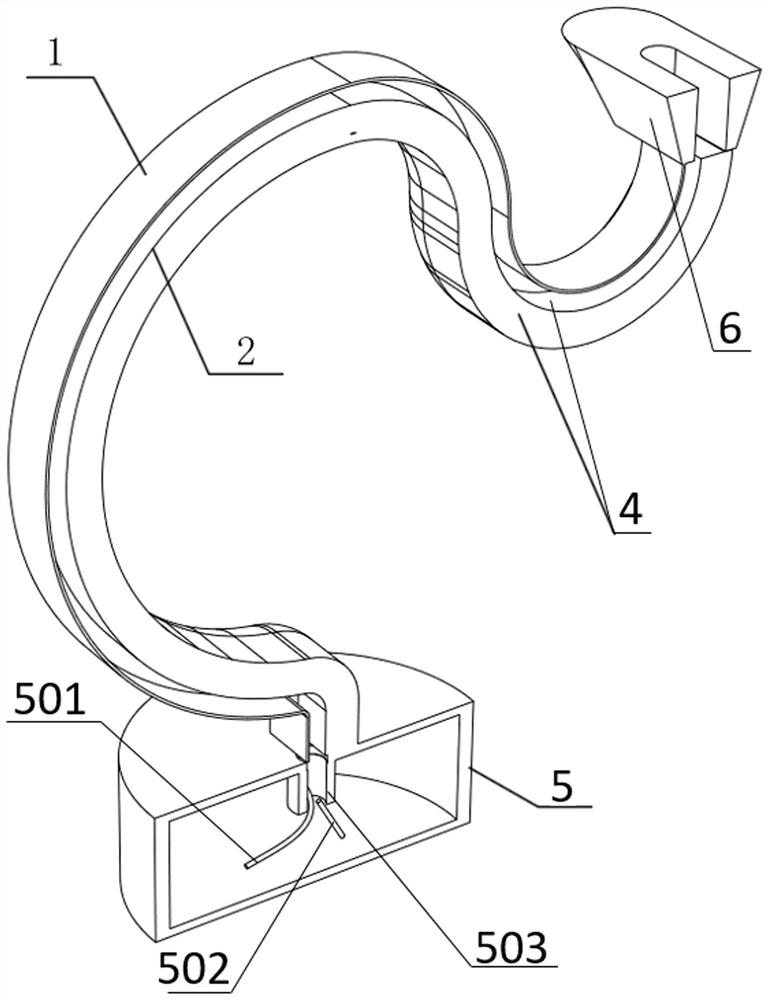

[0029] As shown in the figure, a flexible actuator driven by a chemical release energy reaction, including

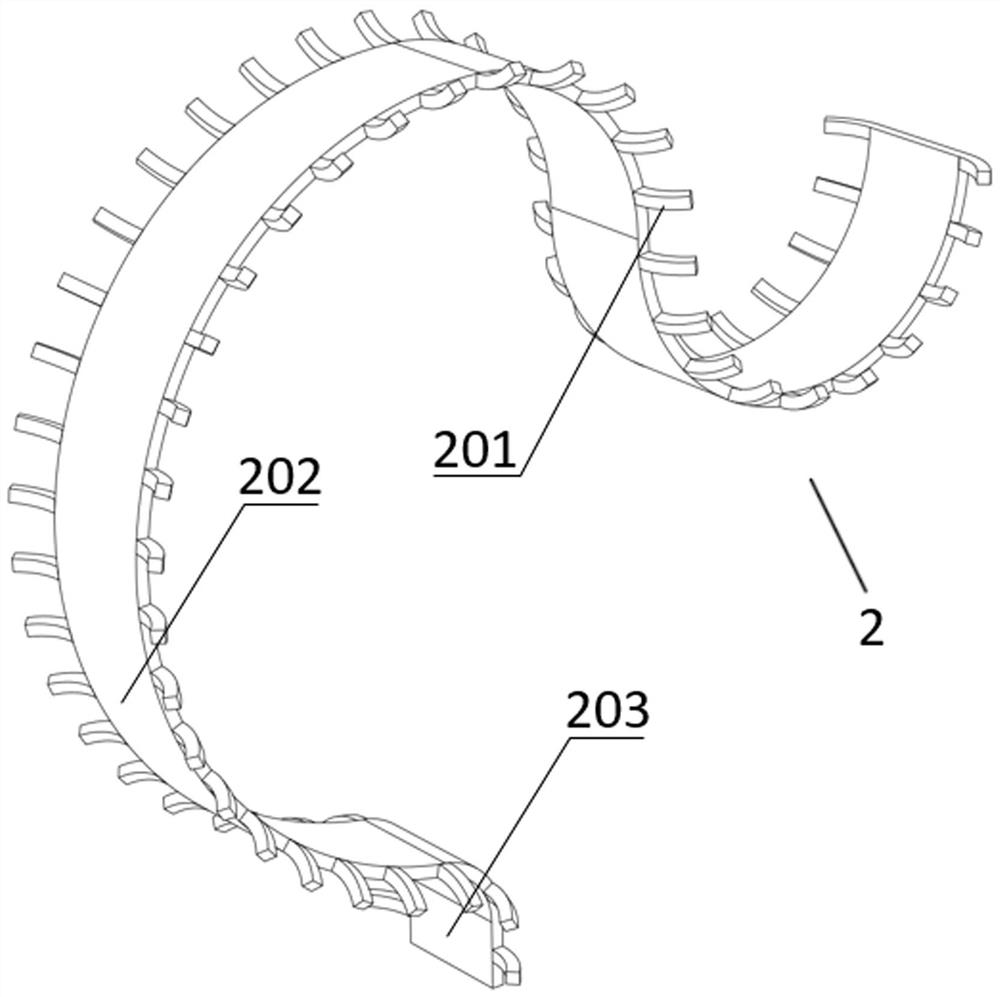

[0030] The main body of the actuator, the actuator body includes an execution skeleton 2 and a flexible execution membrane 1, the flexible execution membrane 1 has a hollow fluid passage 4 inside, the execution skeleton 2 is arranged in it along the length direction of the hollow fluid passage 4 and the hollow fluid passage 4 Separated into front and rear parts;

[0031] Execution terminal 6, the execution terminal 6 is arranged on the upper end of the executor body, which is used to complete the command to be executed; and

[0032] The base 5, the base 5 is used to fix the lower end of the actuator body, and a gas source module 501 and an excitation module 502 are arranged inside, the gas source module 501 is used to provide fuel gas for the hollow fluid channel 4, and the excitation module 502 is used to ignite The fuel gas input into the hollow fluid passage 4 makes...

Embodiment 2

[0044] The difference between this embodiment and Embodiment 1 lies in that the rigidity of the front side surface of the flexible actuator membrane 1 is smaller than that of the rear side surface.

[0045] by Figure 6 , 7 The shown example explains the contact motion principle of a flexible actuator based on chemical reaction technology. The surface stiffness of the rear side of the flexible actuator membrane 1 is set to be higher than the stiffness of the front side surface, fuel gas is continuously input into the front and rear parts of the hollow fluid channel 4 through the gas source module 501, and the injected fuel gas is ignited through the excitation module 502 , an extremely high pressure is generated instantaneously, and the gas pressure acts on the inner surface of the flexible executive membrane 1. Due to the difference in stiffness, the deformation of the front side surface of the flexible executive membrane 1 is much larger than that of the rear side surface, ...

Embodiment 3

[0047] The difference between this embodiment and Embodiments 1 and 2 is that the rigidity of the front side surface of the flexible executive membrane 1 is the same as that of the rear side surface.

[0048] In this embodiment, when the projectile action is performed, more fuel gas is passed into the rear part of the hollow fluid channel 4 through the gas source module 501. The rear side of the flexible actuator membrane 1 produces greater deformation, which drives the actuator body to make a projectile action; when the object is contacted in this embodiment, more air is injected into the front side of the hollow fluid channel 4 through the air source module 501. Both parts of the fuel gas continue to input fuel gas, and the fuel gas passed through is ignited by the excitation module 502, causing greater deformation of the front side of the flexible actuator membrane 1, and driving the actuator body to make a contact action.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com