Rubber product processing device

A technology for processing devices and rubber products, applied in metal processing and other directions, can solve problems such as inability to achieve precise drilling, and achieve the effects of high efficiency, improved accuracy, and improved applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

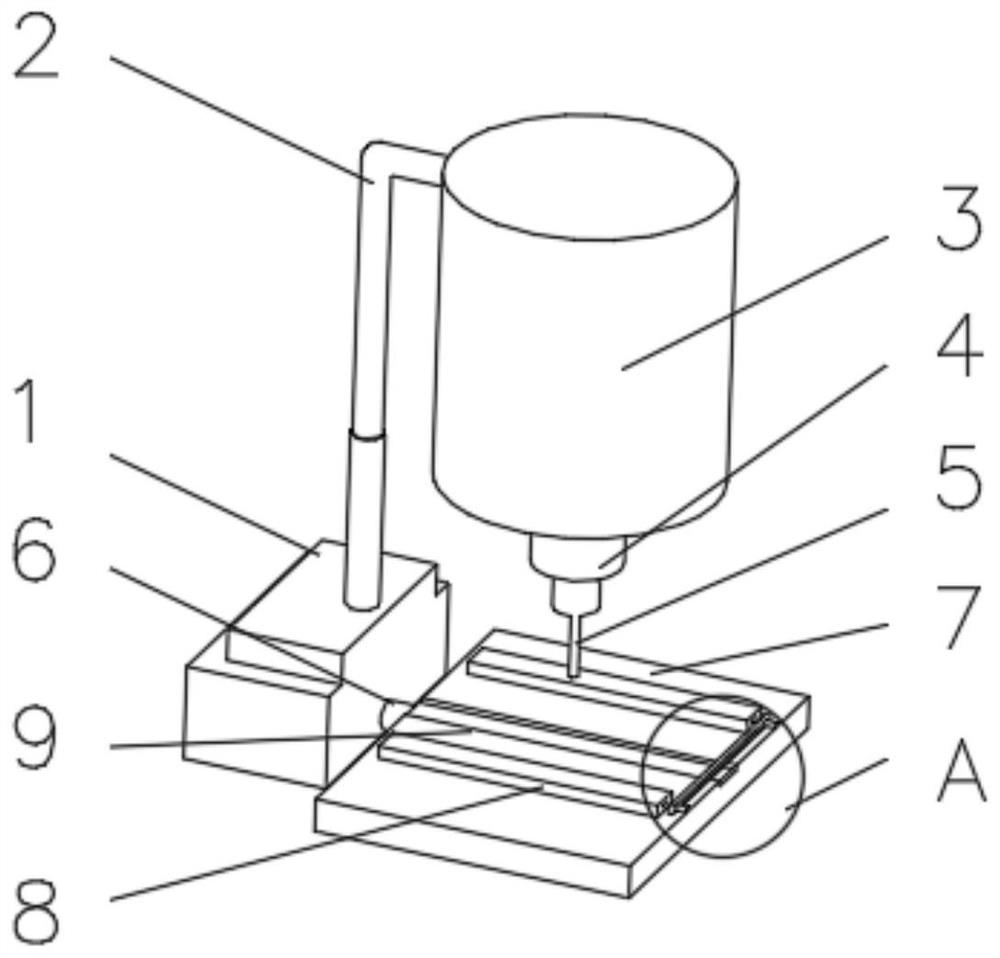

[0031] see Figure 1-2 , the present invention provides a technical solution: a rubber product processing device, including a base 1, a telescopic rod 2 is fixedly connected to the top of the base 1, a motor 3 is installed on the end of the telescopic rod 2 away from the base 1, and the output shaft of the motor 3 rotates Connected with a rotating rod 4, the end of the rotating rod 4 away from the motor 3 is equipped with a drill bit 5, one side of the base 1 is fixedly connected with a positioning plate 7 through a connecting rod 6, and the side of the positioning plate 7 near the drill bit is equipped with a clamping plate 8, A reinforcing plate 9 is fixedly connected to the side of the positioning plate 7 close to the clamping plate 8 , and a clamping device 10 is installed on the side of the clamping plate 8 away from the connecting rod 6 .

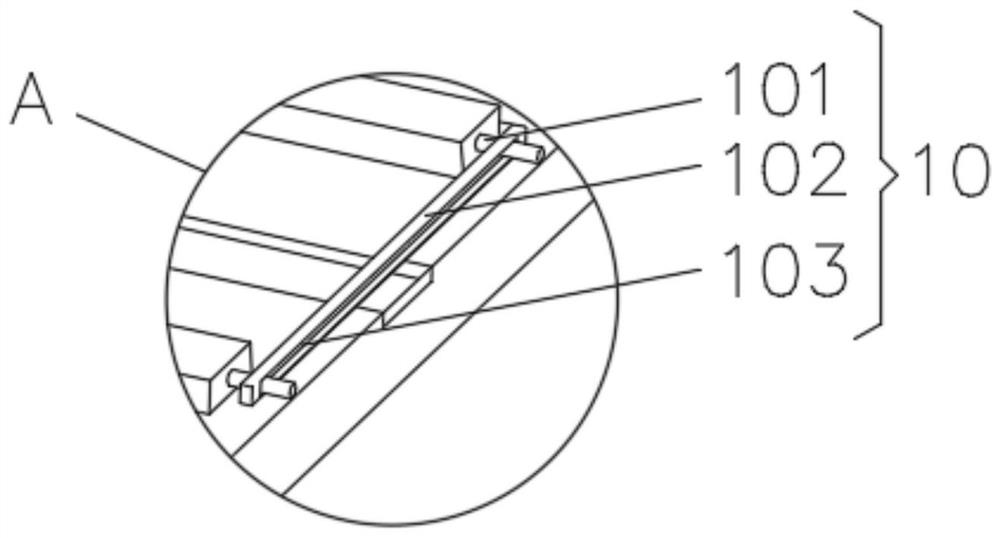

[0032] The clamping device 10 includes a threaded rod 101, one end of the threaded rod 101 is fixedly connected with the clamping pl...

Embodiment 2

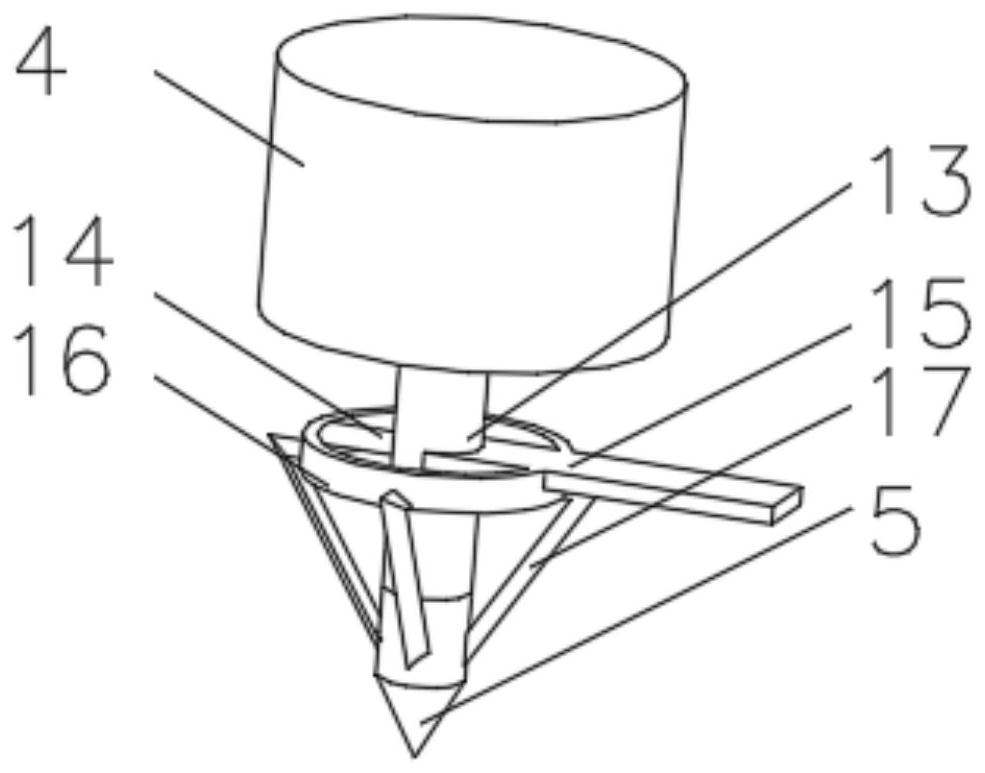

[0035] see Figure 1-5 , the present invention provides a technical solution: on the basis of Embodiment 1, an extension rod 12 is installed on the side of the drill bit 5 close to the rotating rod 4, and the end of the extension rod 12 away from the drill bit 5 is fixedly connected with a hollow rotating shaft 13, and the hollow rotating shaft 13 The outer side of the hollow rotating shaft 13 is rotatably connected with a connecting column 14, and the side of the hollow rotating shaft 13 away from the connecting column 14 is rotatably connected with a scale 15. The end of the connecting column 14 away from the hollow rotating shaft 13 is equipped with a rubber ring 16, and the side of the rubber ring 16 is away from the connecting column. The position of 14 is slidingly connected with scale 15, and the outer bottom of rubber ring 16 is rotatably connected with moving bar 17.

[0036] The inside of the drill bit 5 is equipped with an adjustment device 11, the adjustment device...

Embodiment 3

[0040] see Figure 1-6 , the present invention provides a technical solution: on the basis of Embodiment 2, a groove 19 is provided at one end of the adjustment rod 115 close to the slider 113, a spring 20 is installed on the inner wall of the groove 19, and one end of the spring 20 is fixedly connected with a buffer Block 21, one end of the buffer block 21 is connected with the adjusting rod 115, and the rubber block 22 is symmetrically installed on the side of the buffer block 21 near the spring.

[0041] During use, the moving rod 17 drives the adjusting rod 115 to move, and the adjusting rod 115 is pushed to extrude the spring 20 to move toward the buffer block 21. The rubber block 22 installed on one side of the buffer block 21 touches the inner wall of the groove 19, and the buffer block and The installation of the spring achieves the effect of buffering and damping the adjustment rod, and improves the service life of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com