Automatic circle cutting device for wooden grate for food steamer

A grate and wooden technology, which is applied in the field of automatic round cutting device for wooden grates for steamers, can solve the problems of inability to realize automatic round cutting, rounding of wooden grates, and poor quality of finished products, so as to achieve good round cutting effect, improve work efficiency, and automate high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

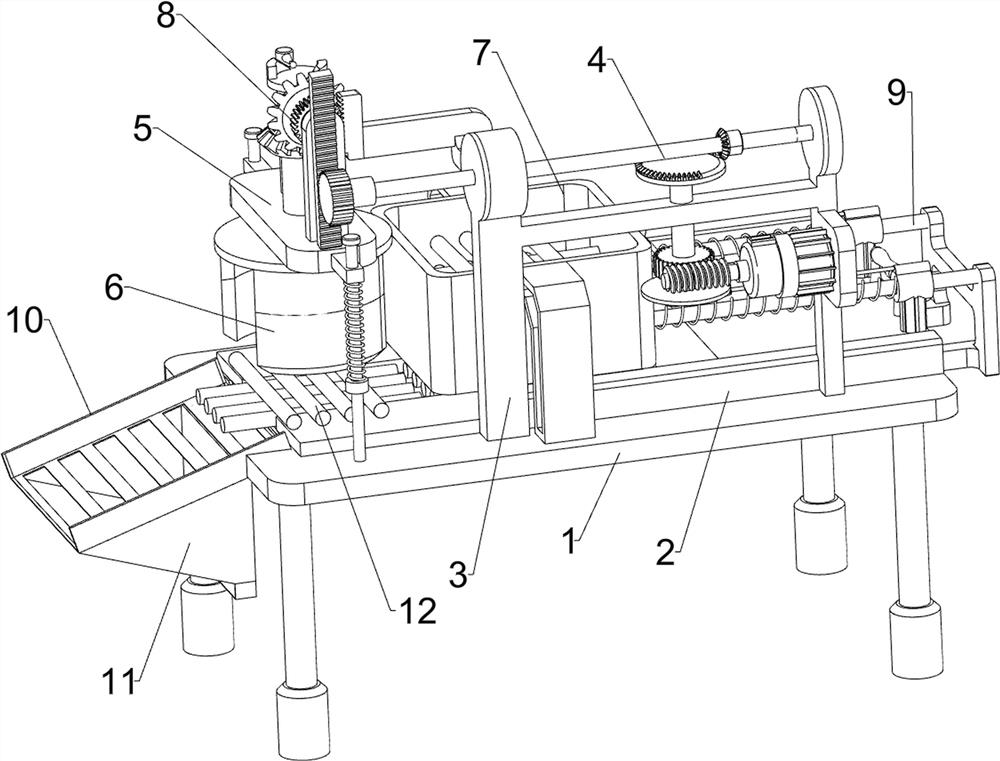

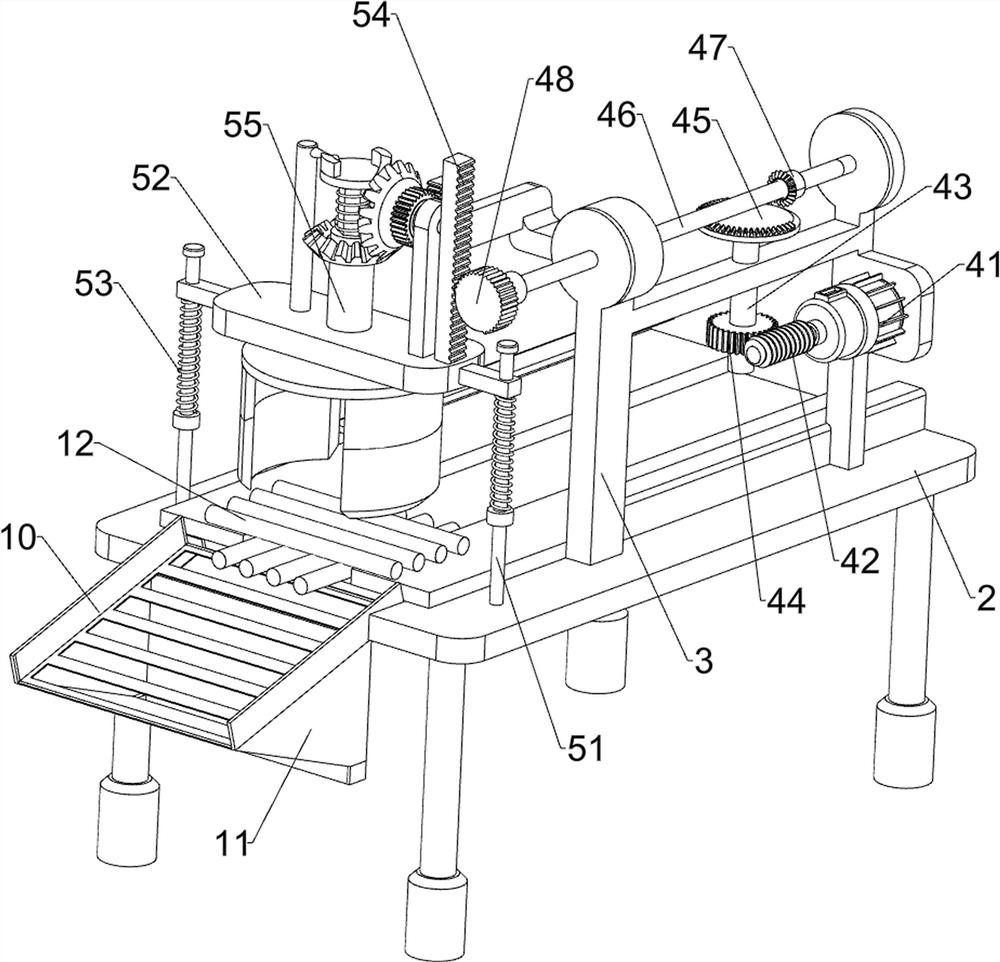

[0028] A wooden grate automatic circle cutting device for steamer, please refer to Figure 1 to Figure 3 As shown, it includes a frame 1, a guide plate 2, a mounting frame 3, a power mechanism 4, an elevating mechanism 5 and a cutting assembly 6. The guide plate 2 is installed in the middle of the top of the frame 1, and the top front side of the frame 1 is connected with a Mounting frame 3, power mechanism 4 is installed on the mounting frame 3, elevating mechanism 5 is installed on the left side of frame 1 top, elevating mechanism 5 and power mechanism 4 transmission cooperates, and cutting assembly 6 is installed on the elevating mechanism 5.

[0029] The power mechanism 4 includes a servo motor 41, a worm screw 42, a first rotating shaft 43, a worm wheel 44, a three-quarter missing bevel gear 45, a second rotating shaft 46, a first bevel gear 47 and a sector gear 48, and the right side of the mounting frame 3 Servomotor 41 is installed, and the output shaft of servomotor 4...

Embodiment approach 2

[0034] On the basis of Embodiment 1, please refer to image 3 and Figure 4 As shown, it also includes a feeding assembly 7, and the feeding assembly 7 includes a connecting frame 71, a material blocking frame 72, a push plate 73 and a handle 74, and two connecting frames 71 are installed in the middle of the top of the frame 1, and the two connecting frames 71 are in the form of Front and back are arranged symmetrically, a material retaining frame 72 is connected between the two connecting frames 71, a push plate 73 is slidably connected to the right part of the guide plate 2, and a handle 74 is connected to the right end of the top of the push plate 73.

[0035] Place the wooden frame 12 in the material retaining frame 72, and the bottom wooden frame 12 is in contact with the top of the frame 1. When the wooden frame 12 needs to be cut, manually hold the handle 74 and push it to the left, and the push plate 73 will move to the left accordingly. Move to the left, the push pl...

Embodiment approach 3

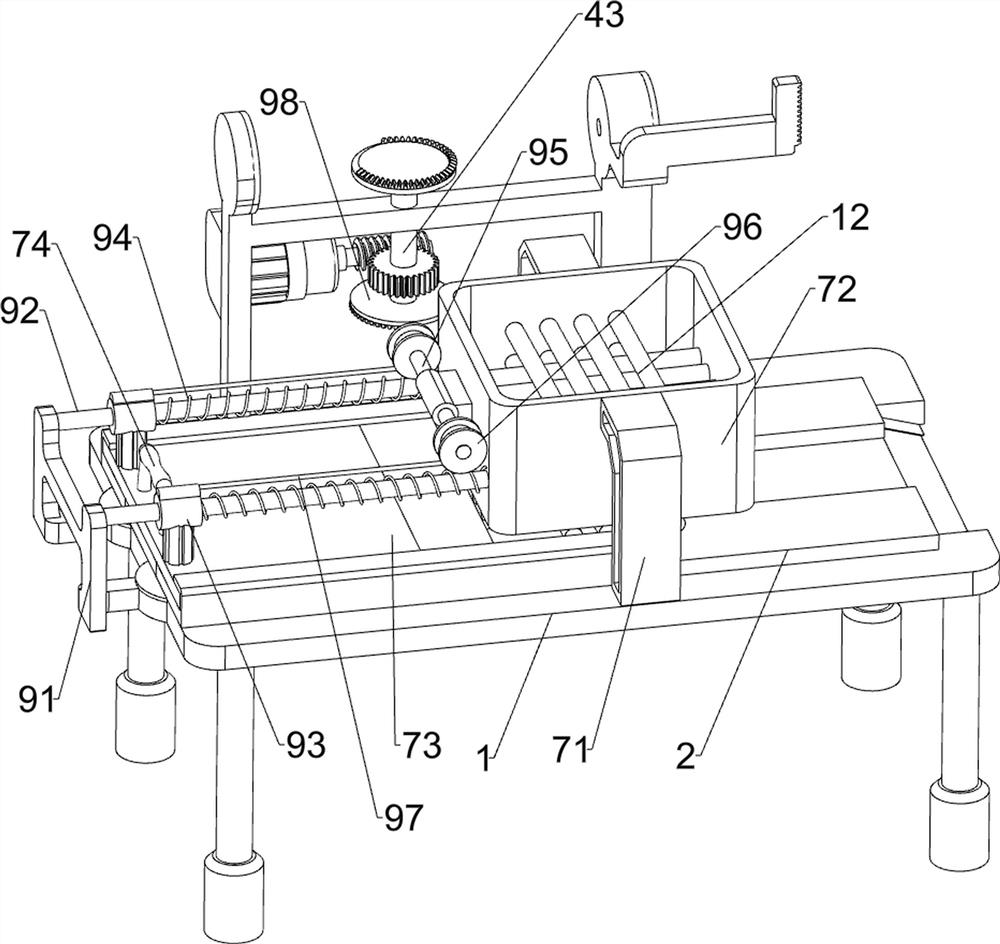

[0039] On the basis of the second implementation mode, please refer to figure 1 , Figure 4 and Figure 5 As shown, it also includes a pusher linkage mechanism 9, and the pusher linkage mechanism 9 includes a fixed frame 91, a transverse guide rod 92, a sliding sleeve 93, a compression spring 94, a connecting shaft 95, a winding reel 96, a backguy 97, a quarter One tooth-missing bevel gear 98 and the second bevel gear 99, the right end of the frame 1 is connected with a fixed frame 91, two horizontal guide rods 92 are horizontally connected between the fixed frame 91 and the retaining frame 72, and the two horizontal guide rods 92 It is symmetrically arranged front and back, and a sliding sleeve 93 is slidably connected to the horizontal guide rod 92, the bottom of the sliding sleeve 93 is connected with the top of the push plate 73, and a compression spring 94 is connected between the sliding sleeve 93 and the retaining frame 72, and the compression spring 94 Sleeved on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com