Sewage filtering device

A technology for sewage and driving devices, which is applied in the fields of filtration treatment, water/sewage treatment, and water/sewage treatment equipment, etc., can solve the problems that need to be improved, and achieve the effect of improving the speed of sewage treatment, ensuring smooth operation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

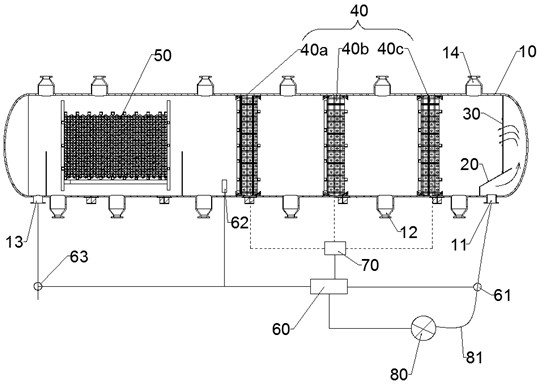

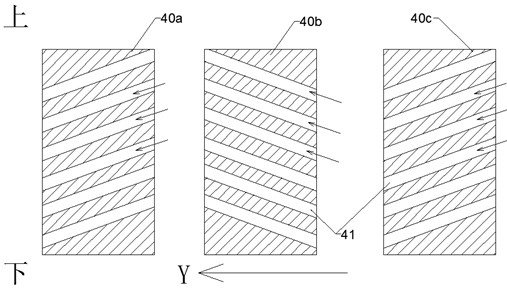

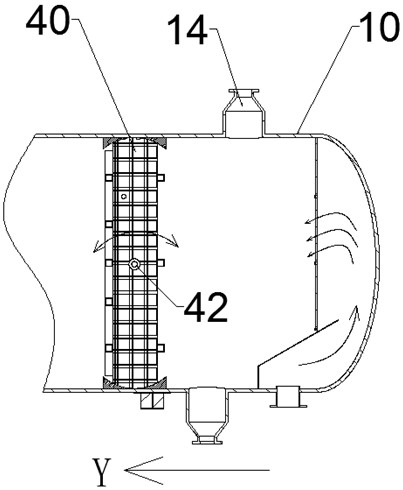

[0047] A device for sewage filtration provided in this embodiment, such as figure 1 As shown, it includes a tank body 10 , a pump body 80 , a controller 60 , and a driving device 70 for driving the primary filtration device 40 to rotate. The primary filtration group includes three primary filtration devices 40 arranged at intervals in the tank body 10 , namely a first primary filtration device 40a, a second primary filtration device 40b and a third primary filtration device 40c. refer to figure 2 As shown, the primary filtration device 40 is provided with flow channels 41 communicating with both sides.

[0048] The tank body 10 is provided with a steady flow device 20, a rectification device 30, a primary filtration group and an oil gathering device 50 in sequence along the direction of water flow; the tank body 10 is provided with a medium inlet 11 at the sewage inlet end, and a Drain 13. A sludge outlet 12 is provided at the bottom of the tank body 10 , at least between ...

Embodiment 2

[0060] This embodiment is basically the same as Embodiment 1, the difference is:

[0061] Such as Figure 4 As shown, the primary filtration device 40 includes: a mounting frame 43 and a plurality of primary filtering corrugated plates 44; the primary filtering corrugated plates 44 can be horizontally slidably arranged on the mounting frame 43 in a direction perpendicular to the water flow direction Y; Specifically, the top and the bottom of the installation frame 43 are provided with slide grooves perpendicular to the water flow direction Y, and the upper and lower ends of the primary filtering corrugated plate 44 are slidably inserted into the slide grooves. An end spring 45 is arranged between the installation frame 43 and the primary filter corrugated plates 44 on the front and rear sides, and a spacer spring 46 is arranged between two adjacent primary filter corrugated plates 44, and two adjacent primary filter corrugated plates 44 are provided with spacer springs 46. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com