Automatic tapping method based on synergic movement of converter and buggy ladle

A technology of coordinated movement and ladle car, which is applied in the direction of manufacturing converters, casting molten material containers, manufacturing tools, etc., can solve the problems that the coordinated movement of ladle cars has not been mentioned, and the influence of steel tapping cannot be solved, so as to prevent steel overflow Possibility, the effect of avoiding excessive slag discharge and avoiding potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

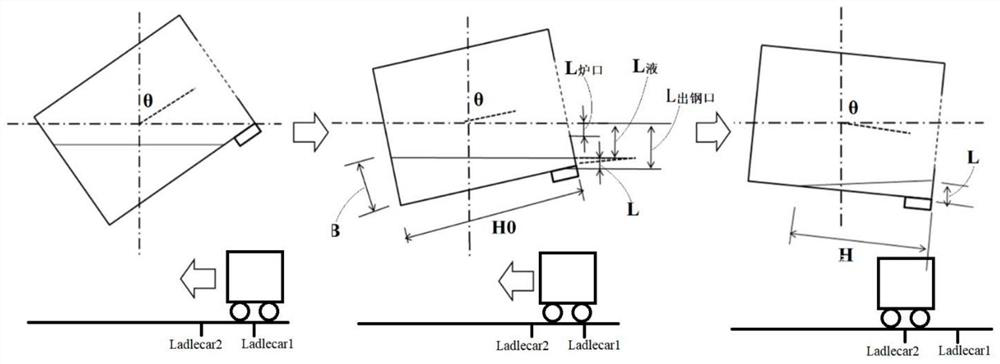

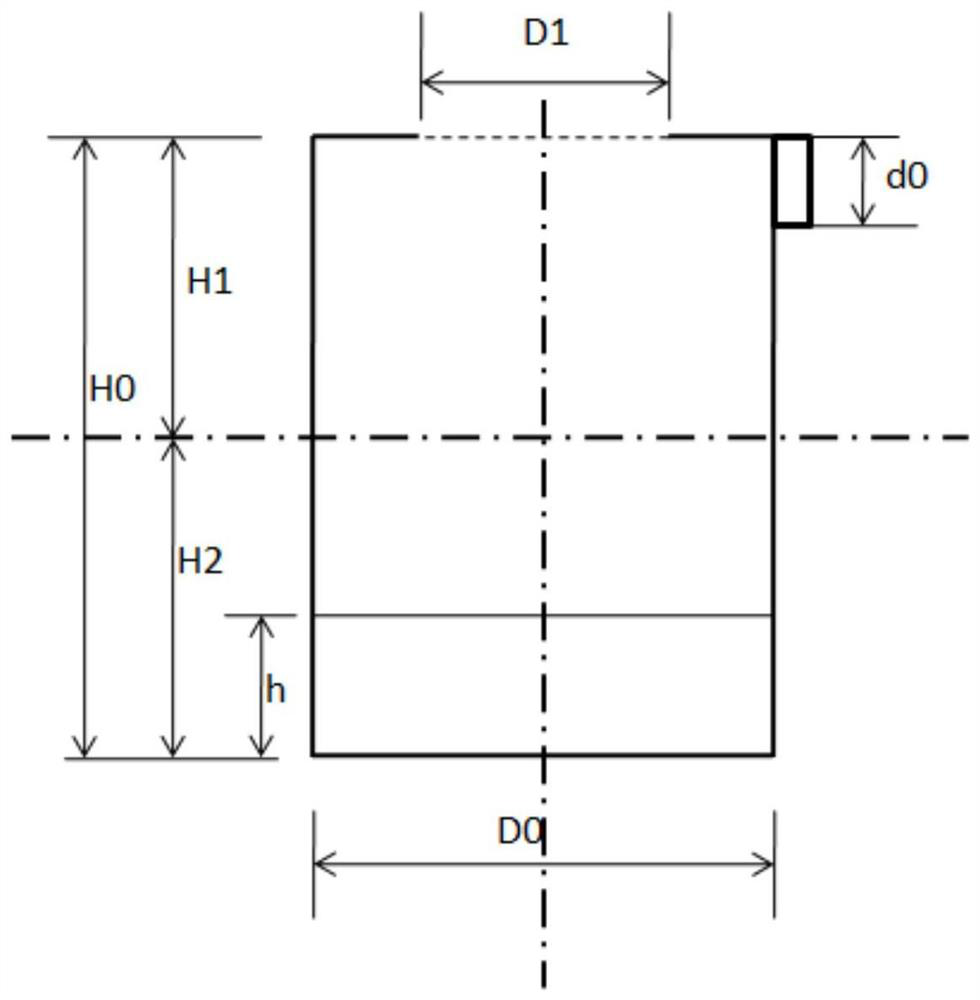

[0091] An automatic tapping method based on the coordinated movement of the converter and the ladle car in this embodiment, when the converter needs to be tapped, the converter is rotated and dumped, when the liquid steel level overflows the tapping hole and reaches the top of the tapping hole When the furnace cap is used, according to the vertical distance L from the molten steel level to the tapping hole, when L reaches 0.10m to 0.30m, the tapping hole is opened for tapping; and the value of L is kept during the tapping process, and its The lower limit of fluctuation is 0.02m, and the upper limit of fluctuation is 0.10m until the end of molten steel dumping. The above molten steel pouring method can ensure that during the tapping process, the steel slag on the surface of the molten steel can be kept away from the tapping port to avoid excessive slag discharge; at the same time, it can ensure that the molten steel is kept away from the furnace mouth of the converter, and to a ...

Embodiment 2

[0152] In this embodiment, taking a 200-ton converter in a factory as an example, when L is 0.28m, the tapping port is opened for tapping; the converter is tapped according to the above method.

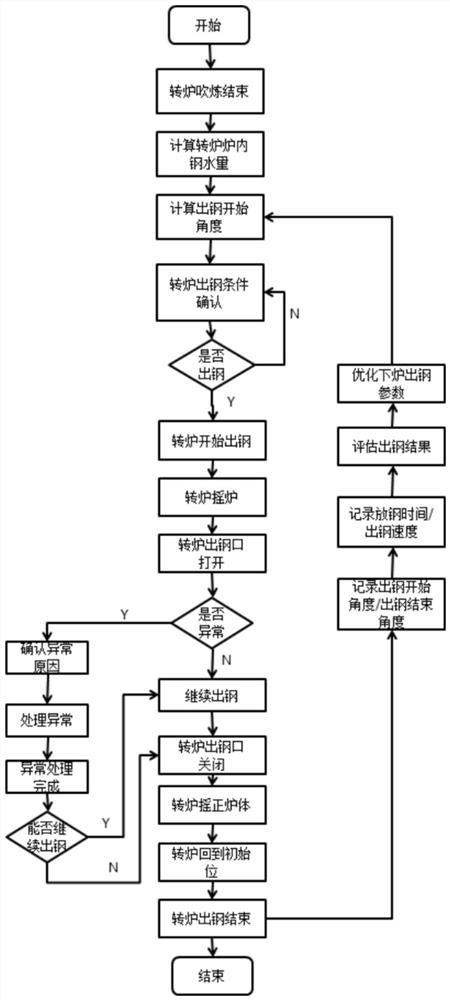

[0153] Embodiments 1 and 2 provide a shaking furnace method for tapping steel from a converter. The converter first dumps and taps the steel, and then the converter returns to normal. The method of dumping and tapping the converter is the molten steel dumping method described in the previous embodiments 1 and 2. The specific process is as image 3 shown.

[0154] According to the statistics of the application effects of Embodiment 1 and Embodiment 2, the yield of iron and steel materials has been increased by 0.17% and 0.18% respectively, and the loss of iron element has been reduced. The following table is the implementation process statistics.

[0155] Implementation of the use effect statistics table (main raw material molten steel yield)

[0156]

[0157]

[0158] Embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com