Metal strip flame heating device and heating method thereof

A metal strip and flame heating technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of large energy consumption, inability to achieve energy storage effects, and inability to achieve uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

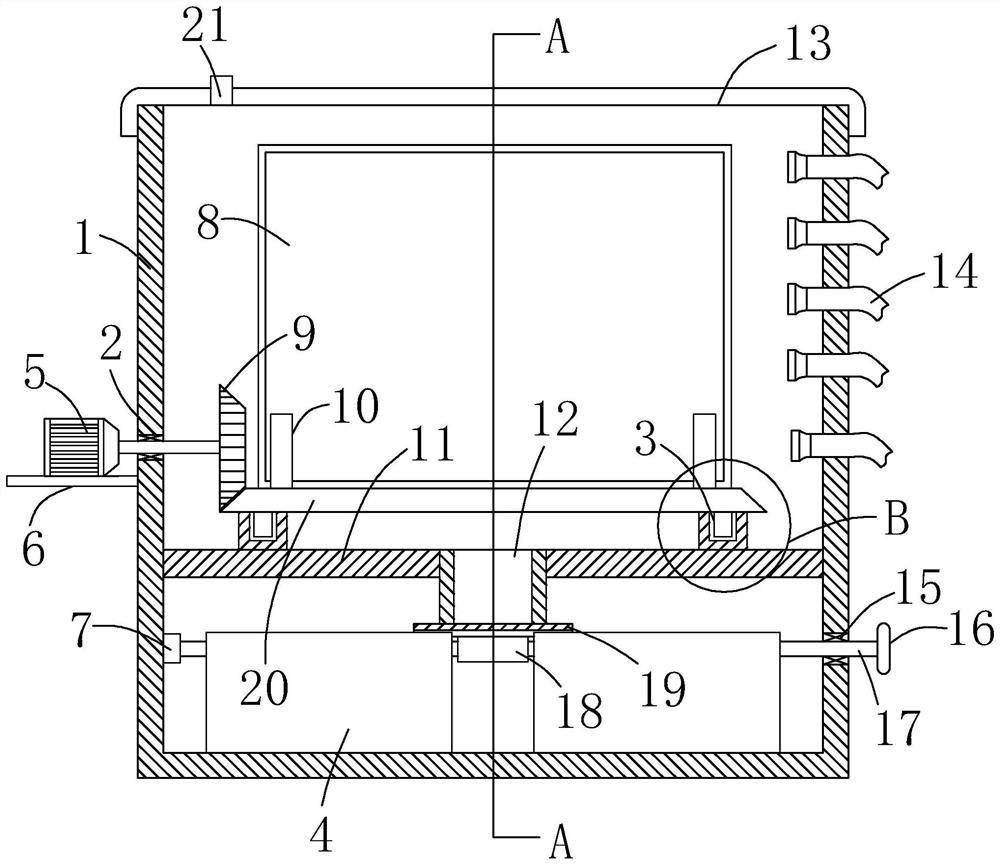

[0024] refer to Figure 1-4 , a metal plate with flame heating device, including a casing 1, the upper end of the casing 1 is screwed with an upper cover 13, the upper end of the upper cover 13 is installed with a gas pipe 21 penetrating the upper cover 13, and the gas pipe 21 can prevent the casing The heat inside the 1 increases, which causes the upper cover 13 to be subjected to a large lifting force, resulting in wear of the upper cover 13 .

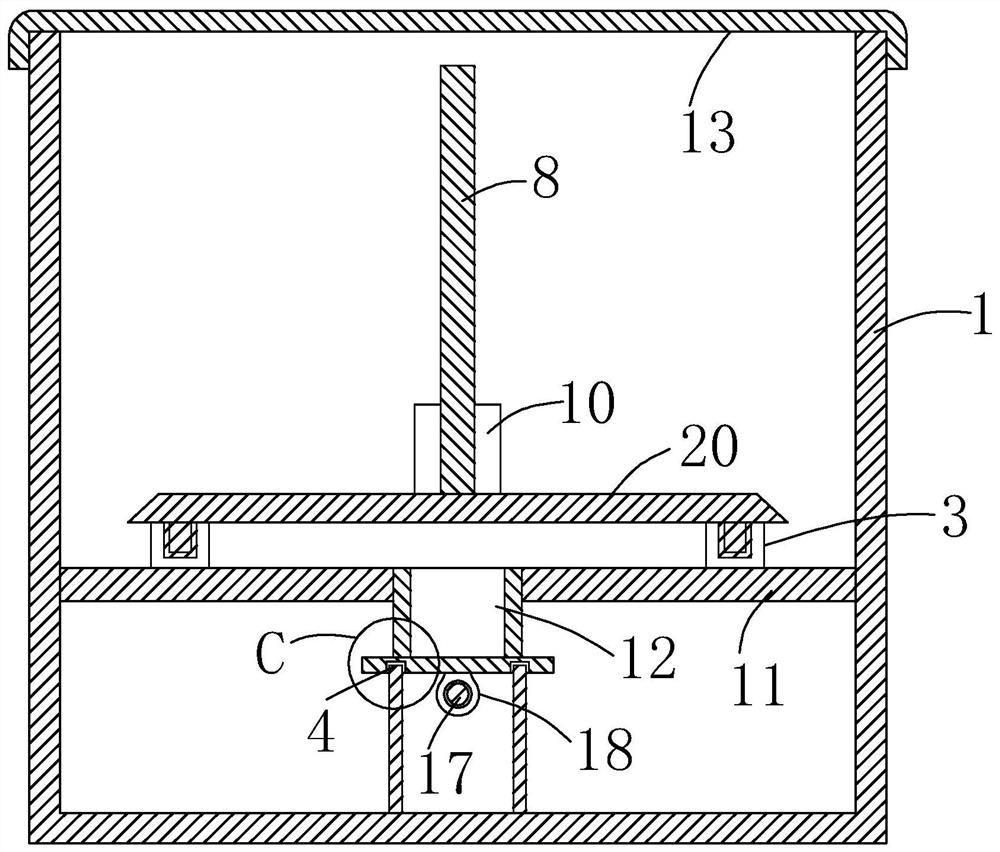

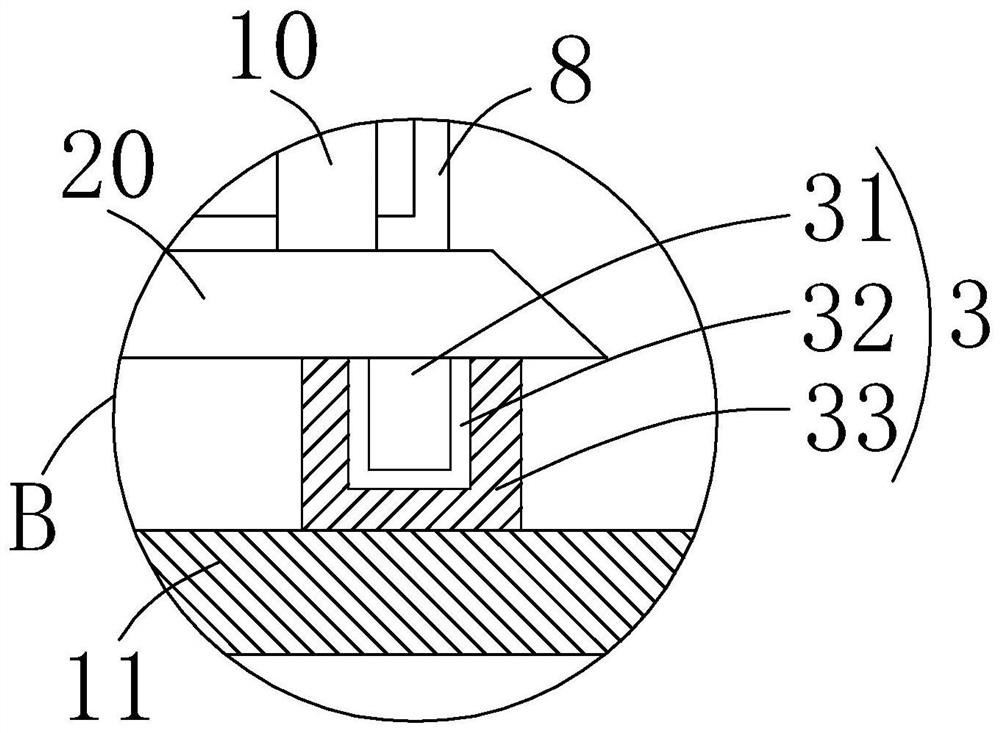

[0025] A fixed plate 11 is horizontally welded to the lower end of the inner side of the housing 1, and the lower end of the fixed plate 11 is provided with a temperature storage mechanism. The moving mechanism includes a shaft seat 7 fixedly installed on one side of the lower end of the casing 1 and a sealed bearing 15 installed on the other side of the lower end of the casing 1 . , one end of the threaded rod 17 extends to the inner side of the shaft seat 7, and the threaded rod 17 is also threadedly connected with a threaded slee...

Embodiment 2

[0033] refer to figure 1 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the gear plate 20 and the middle end of the outer side of the casing 1 are provided with a power mechanism, and the power mechanism includes a fixed installation on the outer side of the casing 1. The support plate 6 and the bearing 2 installed in the middle part of one side of the housing 1, the upper end of the support plate 6 is fixed with a stepping motor 5 by screws, and the output shaft of the stepping motor 5 penetrates the bearing 2 and extends to the inner side of the housing 1, The main gear 9 is installed vertically at the end of the output shaft of the stepping motor 5 inside the housing 1, and the main gear 9 and the gear plate 20 are meshed with each other. External control switch, the stepper motor 5 drives the main gear 9 to rotate, and the main gear 9 and the gear plate 20 are meshed with each other, so that the gear plate 20 rotates in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com