Method for monitoring combustible gas concentration of biomass stack to prevent spontaneous combustion

A gas concentration and biomass technology, which is applied in the field of material stacking safety detection, can solve the problems of inability to degrade and release flammable gas, the level of spontaneous combustion warning needs to be improved, and real-time online monitoring cannot be realized, so as to improve reliability and prediction level, The effect of avoiding fire accidents and preventing stacking spontaneous combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

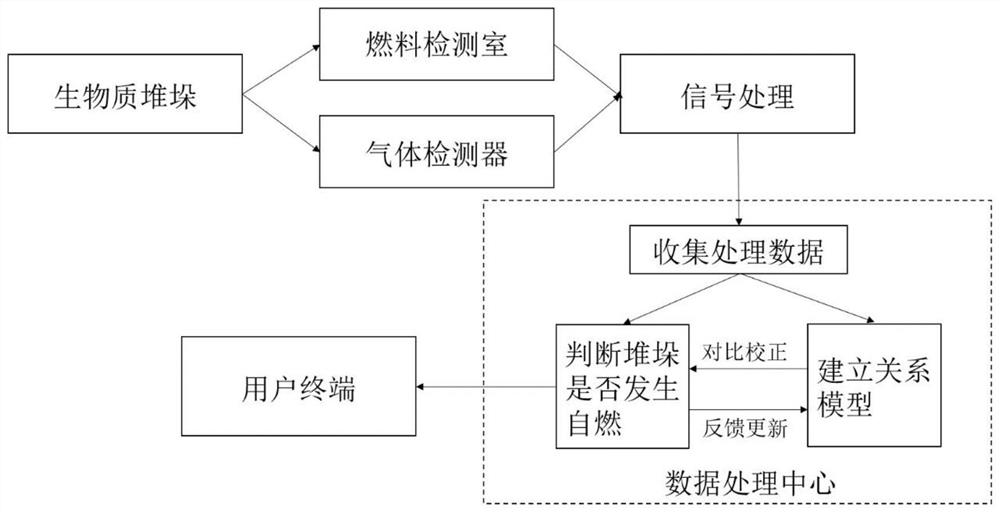

[0018] ginseng figure 1 As shown, this embodiment is a method for monitoring the concentration of combustible gas in a biomass stack to prevent spontaneous combustion, including:

[0019] The concentration of flammable gases (such as methane, etc.) released by the degradation of biomass stacks is detected in real time based on the gas detector installed in the stacks of the biomass field.

[0020] In the fuel testing room, the regularly sampled stack samples are tested through industrial analysis, and the water content and sludge content in the stack are measured; the sampling and testing period can be determined according to the actual situation on site.

[0021] In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com