Electronic detonator explosion work testing method

An electronic detonator and testing method technology, which is applied in the direction of fuel oil testing, measuring devices, and blasting force measurement, can solve problems such as experiment failure, detonator working ability deviation, volume reading error, etc., and achieve high experimental accuracy and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Fix the electronic detonator and the pressure sensor on a metal rod to keep them on the same horizontal line, and keep a certain distance at the level.

[0050] Put the fixed electronic detonator and pressure sensor into the explosion pool, the depth is 1 / 2 of the depth of the pool, and bind a certain weight of objects under the electronic detonator or the electronic detonator inserted into the charge pack to ensure that it and the pressure sensor are underwater Still level.

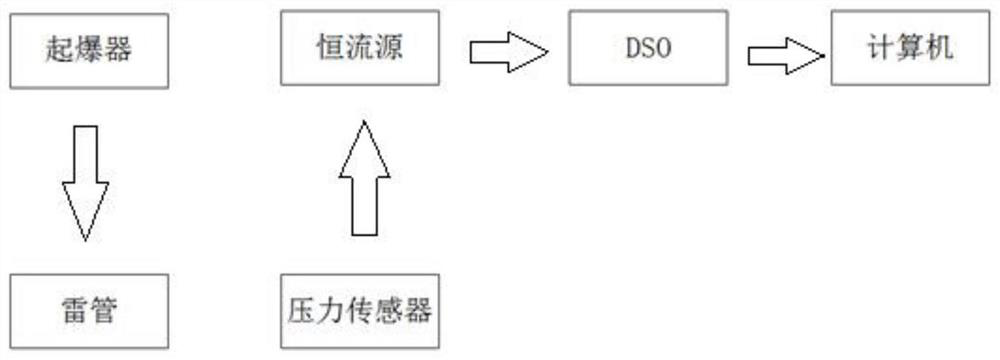

[0051] Connect the electronic detonator to the detonating device, the pressure sensor to the constant current source, the DSO and the computer.

[0052] After connecting the device and detonating it, record the data obtained.

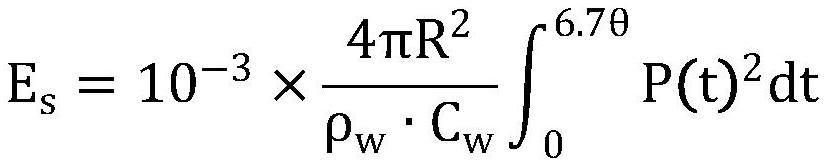

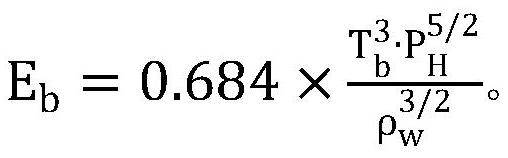

[0053] The shock wave energy and bubble energy of the electronic detonator alone are recorded as E1 from the calculated data, and the shock wave energy and bubble energy of the electronic detonator inserted into the charge package are recorded as E2, so the actual working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com