Low viscosity compositions and 3D printing methods utilizing compositions

一种组合物、3D的技术,应用在有机硅弹性体,制备此类组合物和有机硅弹性体,3D弹性体制品领域,能够解决缓慢、低分子量、差机械特性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

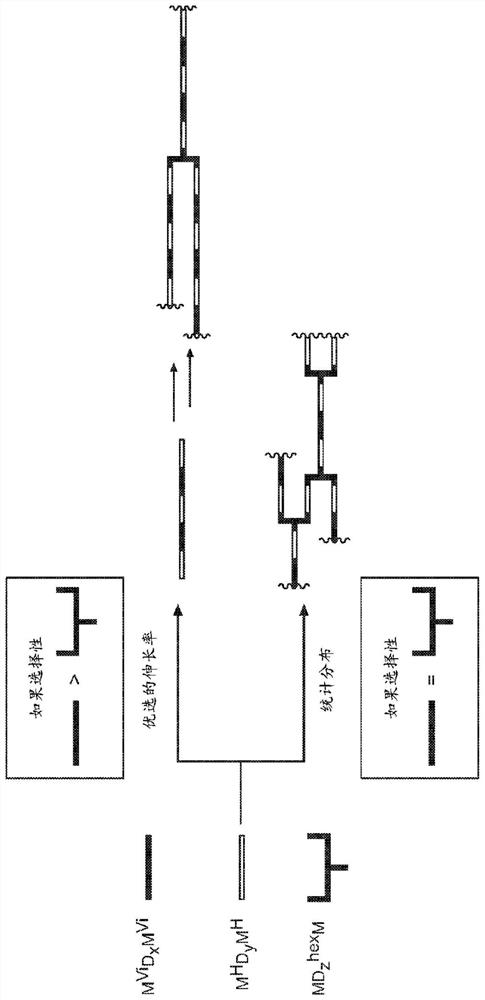

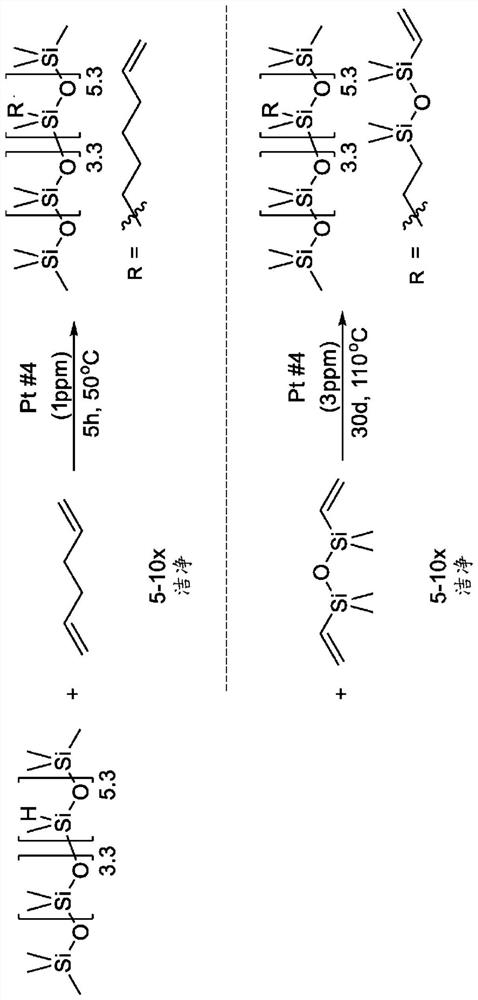

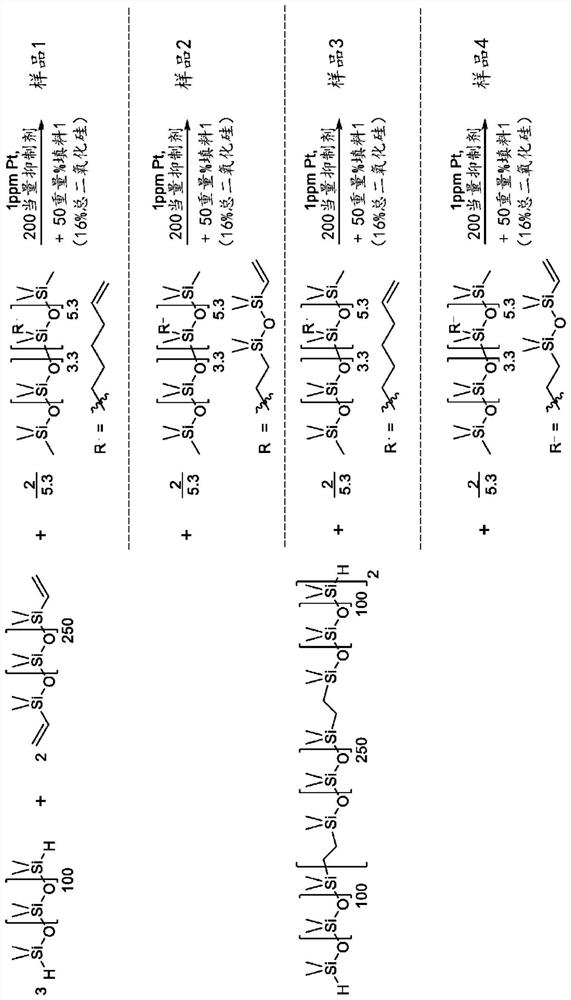

[0241] Exemplary elastomeric systems were designed and tested. It was determined that preferential reactivity enables chain extension of the vinyl functional component, which is then effectively crosslinked through the use of the hexenyl functional component. Thus, it is feasible to formulate elastomeric systems with lower molecular weight precursors (and thus significantly lower viscosity), while maintaining elongation, strength and toughness similar to conventional formulations comprising higher molecular weight polymers. In the examples shown herein, the viscosity of the uncured system was reduced by more than two (2) orders of magnitude, while the cured product exhibited similar modulus and elongation.

[0242] The different reactivity of the hexenyl and vinylsilyl functional groups was used to construct silicone elastomers with high elongation % and stress at break. Use terminal vinyl (M vi D. n m vi ) and terminal silyl hydride (M H D. m m H ) linear polymers, via...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com