Cookware, preparation method thereof and cooking equipment

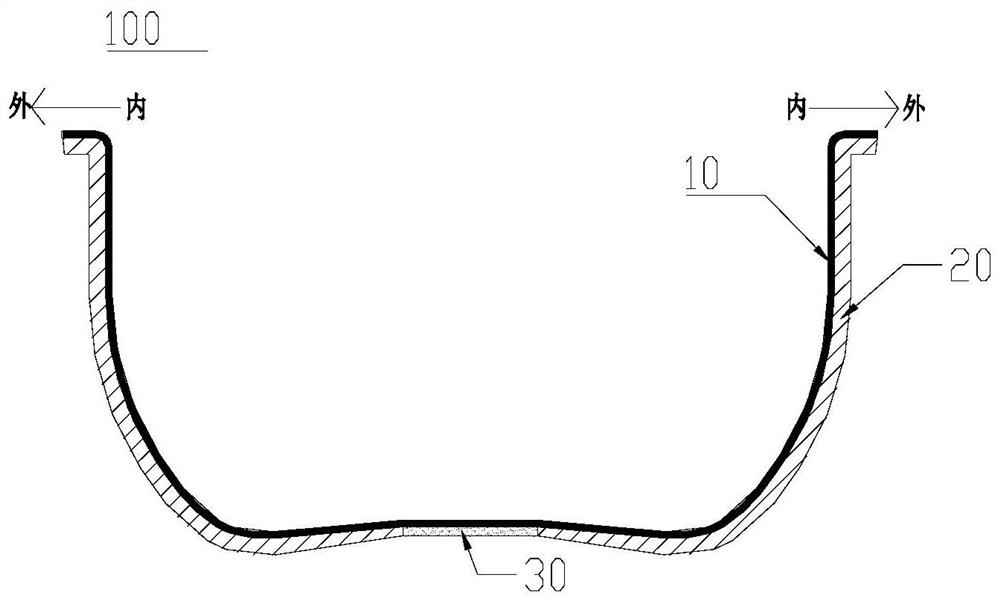

A pot and square technology, applied to the structure of cooking utensils, special materials for cooking utensils, cooking utensils, etc., can solve the problems affecting the accuracy of the sensor, the magnetic layer and the temperature sensor are not in close contact, etc., to achieve good compactness, Good binding force and improved compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Degrease and degrease the outer surface of the base material of the aluminum alloy pan;

[0047] Through the first cold spraying, the first magnetic conduction area is formed on the outer surface of the bottom of the pot base material, wherein the spraying pressure of the first cold spraying is 6Mpa, and the spraying temperature is 1000°C;

[0048] Through the second cold spraying, a second magnetically permeable region is formed on the outer surface of the pot base material and around the first magnetically permeable region, wherein the spraying pressure of the second cold spraying is 3Mpa, and the spraying temperature is 600°C.

[0049] Wherein, the surface roughness Ra of the first magnetically permeable area is 1 micron, and the porosity is 0.1%; the surface roughness Ra of the second magnetically permeable area is 6 micron, and the porosity is 2.5%.

[0050] The accuracy test method of the temperature sensor: use the temperature inspection instrument, arrange the p...

Embodiment 2

[0056] Degrease and degrease the outer surface of the base material of the aluminum alloy pan;

[0057] Through the first cold spraying, the first magnetic conduction area is formed on the outer surface of the bottom of the pot base material, wherein the spraying pressure of the first cold spraying is 4Mpa, and the spraying temperature is 950°C;

[0058] Through the second cold spraying, a second magnetically permeable region is formed on the outer surface of the pot base material and around the first magnetically permeable region, wherein the spraying pressure of the second cold spraying is 4.5Mpa, and the spraying temperature is 700°C.

[0059] Wherein, the surface roughness Ra of the first magnetically permeable area is 2 microns, and the porosity is 0.5%; the surface roughness Ra of the second magnetically permeable area is 5.2 micron, and the porosity is 2%.

[0060] The accuracy test method of temperature sensor is identical with embodiment 1, and test result is:

[006...

Embodiment 3

[0066] Degrease and degrease the outer surface of the base material of the aluminum alloy pan;

[0067] Through the first cold spraying, the first magnetic conduction area is formed on the outer surface of the bottom of the pot base material, wherein the spraying pressure of the first cold spraying is 3.6Mpa, and the spraying temperature is 900°C;

[0068] Through the second cold spraying, a second magnetically permeable region is formed on the outer surface of the pot base material and around the first magnetically permeable region, wherein the spraying pressure of the second cold spraying is 4.6Mpa, and the spraying temperature is 800°C.

[0069] Wherein, the surface roughness Ra of the first magnetically permeable area is 3 microns, and the porosity is 1%; the surface roughness Ra of the second magnetically permeable area is 2 microns, and the porosity is 0.8%.

[0070] Test method is identical with embodiment 1, and test result is:

[0071] At 1 minute, the temperature of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com