Amorphous alloy additive and preparation method of amorphous alloy component

A technology for amorphous alloys and components, applied in the directions of additive processing, process efficiency improvement, energy efficiency improvement, etc., can solve the problems of inability to realize pure amorphous alloy preparation, small penetration depth, etc., to overcome the formation of nanocrystalline, Effects of high cooling rates, high heating rates, and cooling rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a method for preparing an amorphous alloy additive, the preparation method comprising:

[0034] Use a pulse laser to heat Al to melt, and by limiting the pulse width of the pulse laser to 1 ns, the pulse laser wavelength to 1064 nm, the single pulse intensity of the pulse laser to 0.5 μJ, and the spot size to 5 μm, the melting of the metal material is achieved. Rapid cooling, cooling rate up to 6.1×10 11 K / s.

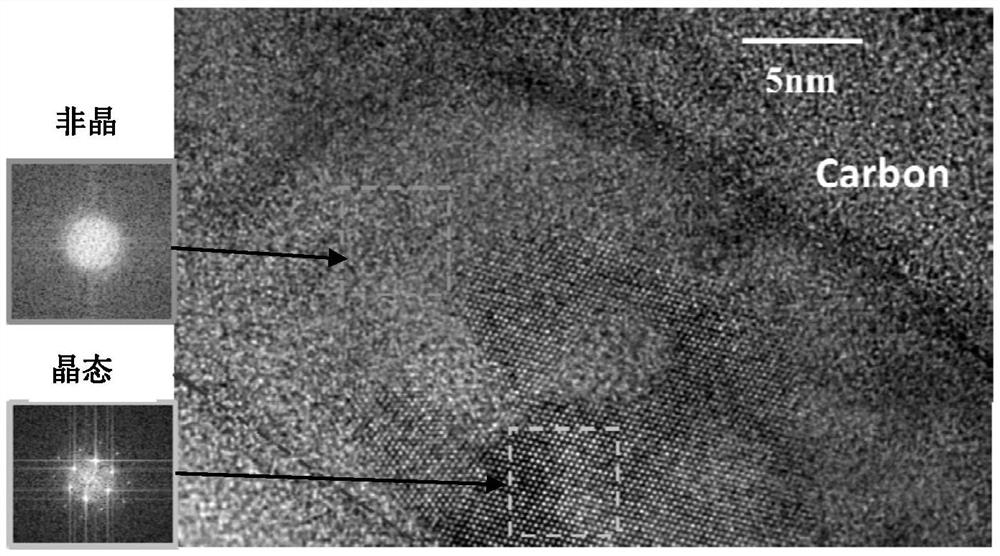

[0035] The TEM image of the amorphous Al sample prepared in this example is as follows figure 1 shown, from figure 1 It can be seen that there is a large area of amorphous area in the cross section of this sample, which is significantly different from the diffraction spot of the surrounding crystalline area without laser pulse heat treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| penetration depth | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com