Pile leg shell section butt joint method

A technology of pile legs and barrel joints, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of unsatisfactory stress relief treatment, difficult welding and installation, easy cracks and deformation, etc. Achieve the effects of good stress relief treatment, good welding quality, and not easy to crack and deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

[0033] This specific embodiment adopts following technical scheme: comprise the following steps:

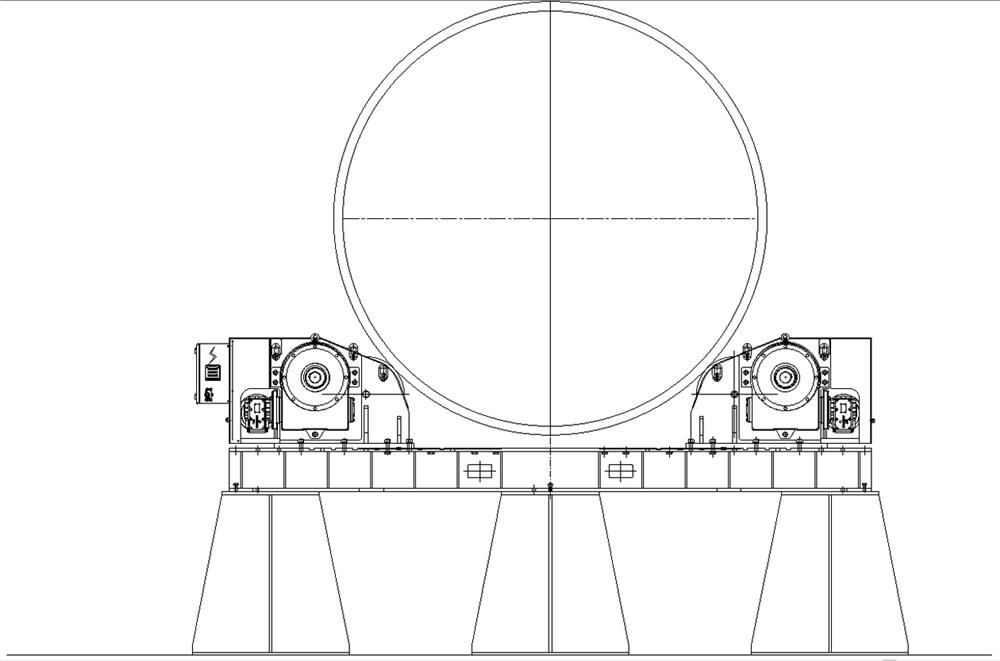

[0034] S1. Roller frame installation: Weld several roller frame supports at intervals on the backing plate of the workshop, arrange several roller frames on the support frame, and arrange the two sections of pile legs that need to be docked on the roller frame, such as figure 1 Shown is the layout state diagram of the roller frame and the support frame.

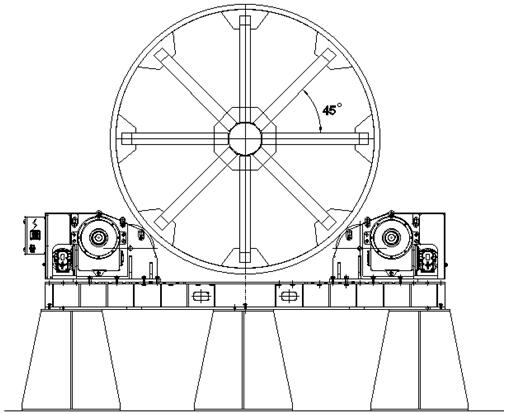

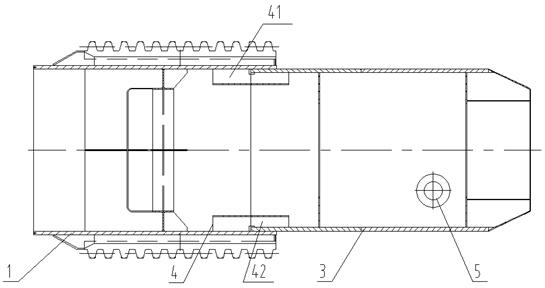

[0035] S2. Pozi-shaped bracing arranged inside the pile leg tube section: Pozi-shaped braces ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com