Glass slurry for automobile compression molding front windshield and preparation method thereof

A front windshield, glass paste technology, applied in the coating and other directions, can solve the problems of insufficient acid and alkali resistance, poor anti-stickiness, etc., and achieves a suitable expansion coefficient range, simple preparation process, excellent acid resistance and resistance. The effect of stickiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

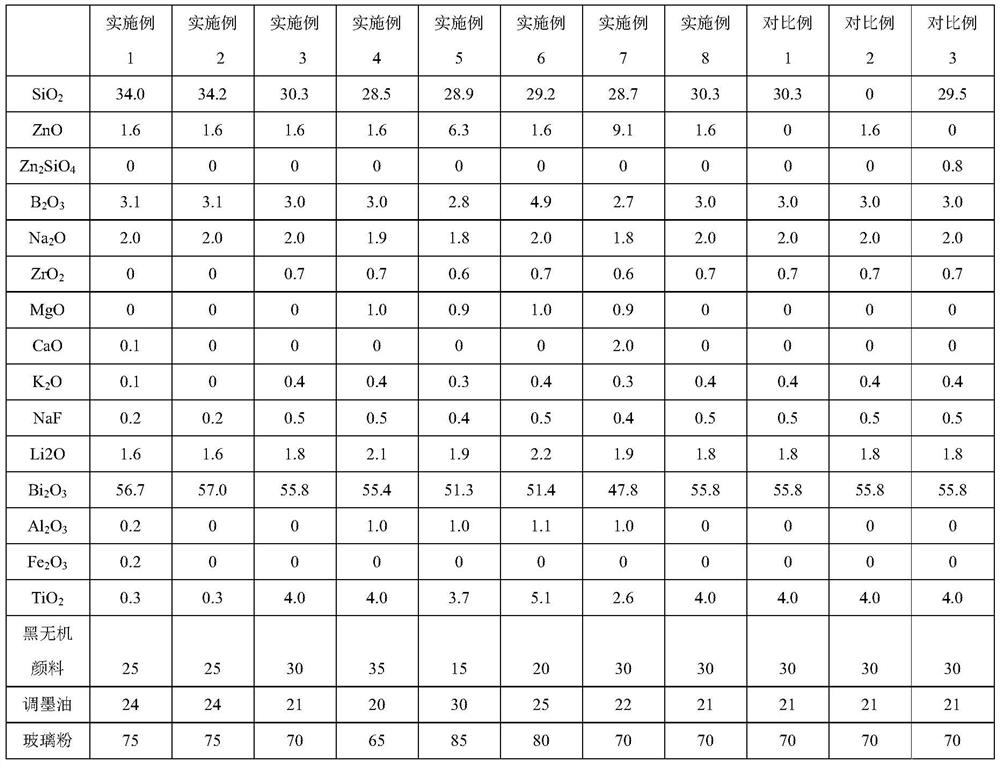

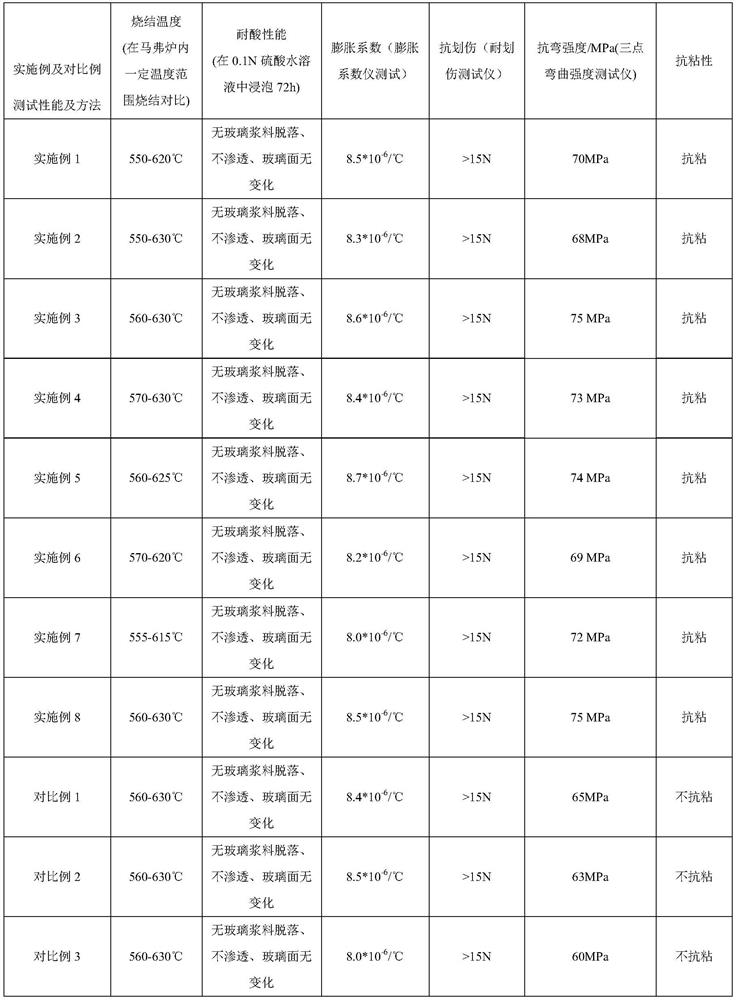

[0059] Preparation of glass powder: weigh Bi 2o 3 : 56.7 parts; SiO 2 : 34.0 copies; B 2 o 3 : 3.1 parts; ZnO: 1.6 parts; ZrO 2 : 0 parts; TiO 2 : 0.3 parts; Al 2 o 3 : 0.2 parts; Fe 2 o 3 : 0.2 parts; NaF: 0.2 parts; MgO: 0 parts; CaO: 0.1 parts; 2 O: 1.6 copies; K 2 O: 0.1 parts; Na 2 O: Add 2.0 parts of glass powder raw materials into the mixer and mix evenly, put the uniformly mixed glass powder raw materials into a crucible, put the crucible with glass powder raw materials in a high-temperature furnace, and melt at a temperature of 1000°C 2 hours to melt the material into a uniformly mixed liquid, quickly pour the melted mixed liquid into distilled water to form glass slag; dry and crush the glass slag, put it in a ball mill with a rotation speed of 200r / min for 2 hours, and then put it into a drying box drying at 200°C, and then sieved to obtain glass powder with an average particle size of 2 μm;

[0060] Preparation of slurry: 75 parts of glass powder obtai...

Embodiment 2

[0062] Preparation of glass powder: weigh Bi 2 o 3 : 57.0 parts; SiO 2 : 34.2 copies; B 2 o 3 : 3.1 parts; ZnO: 1.6 parts; ZrO 2 : 0 parts; TiO 2 : 0.3 parts; Al 2 o 3 : 0 copies; Fe 2 o 3 : 0 parts; NaF: 0.2 parts; MgO: 0 parts; CaO: 0 parts; 2 O: 1.6 copies; K 2 O: 0 parts; Na 2 O: Add 2.0 parts of glass powder raw materials into the mixer and mix evenly, put the uniformly mixed glass powder raw materials into a crucible, put the crucible with glass powder raw materials in a high-temperature furnace, and melt at a temperature of 1000°C 2 hours to melt the material into a uniformly mixed liquid, quickly pour the melted mixed liquid into distilled water to form glass slag; dry and crush the glass slag, put it in a ball mill with a rotation speed of 200r / min for 2 hours, and then put it into a drying box drying at 200°C, and then sieved to obtain glass powder with an average particle size of 2 μm;

[0063] Preparation of slurry: 75 parts of glass powder obtained in...

Embodiment 3

[0065] Preparation of glass powder: weigh Bi 2 o 3 : 55.8 parts; SiO 2 : 30.3 copies; B 2 o 3 : 3.0 parts; ZnO: 1.6 parts; ZrO 2 : 0.7 parts; TiO 2 : 4.0 parts; Al 2 o 3 : 0 copies; Fe 2 o 3 : 0 parts; NaF: 0.5 parts; MgO: 0 parts; CaO: 0 parts; 2 O: 1.8 copies; K 2 O: 0.4 parts; Na 2 O: Add 2.0 parts of glass powder raw materials into the mixer and mix evenly, put the uniformly mixed glass powder raw materials into a crucible, put the crucible with glass powder raw materials in a high-temperature furnace, and melt at a temperature of 1000°C 2 hours to melt the material into a uniformly mixed liquid, quickly pour the melted mixed liquid into distilled water to form glass slag; dry and crush the glass slag, put it in a ball mill with a rotation speed of 200r / min for 2 hours, and then put it into a drying box drying at 200°C, and then sieved to obtain glass powder with an average particle size of 2 μm;

[0066] Preparation of slurry: 70 parts of glass powder obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com