Mask alignment device and mask alignment method

A mask alignment and mask technology, which is applied to instruments, vacuum evaporation plating, coatings, etc., can solve the problems of low measurement accuracy, poor alignment accuracy between metal mask and frame, and improve alignment accuracy. , The effect of improving light utilization and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

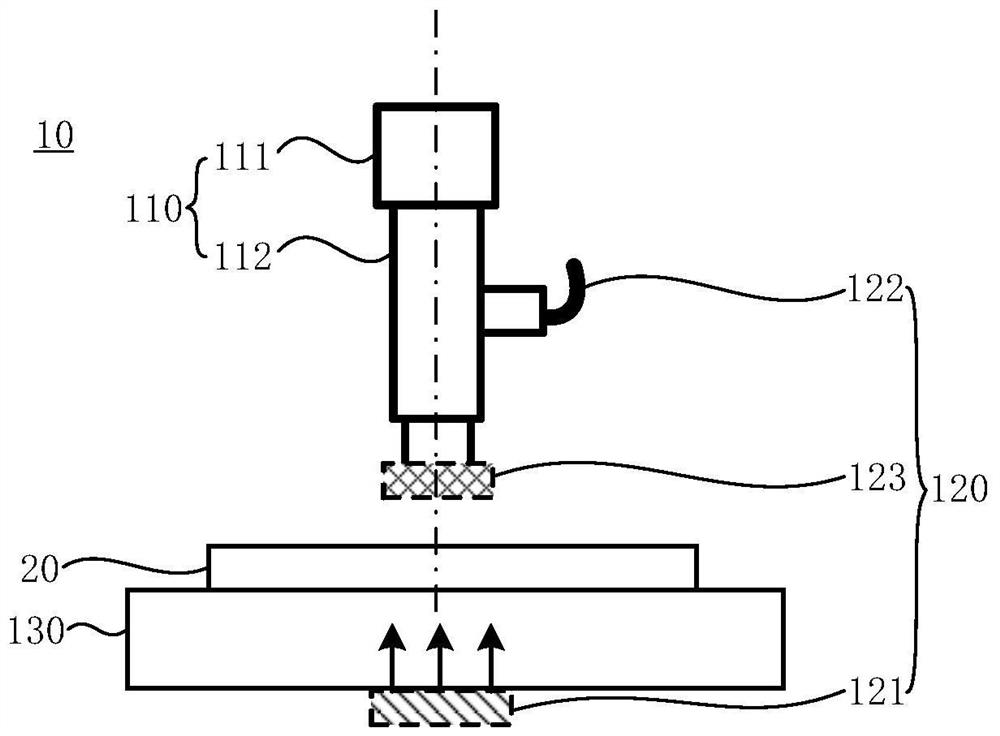

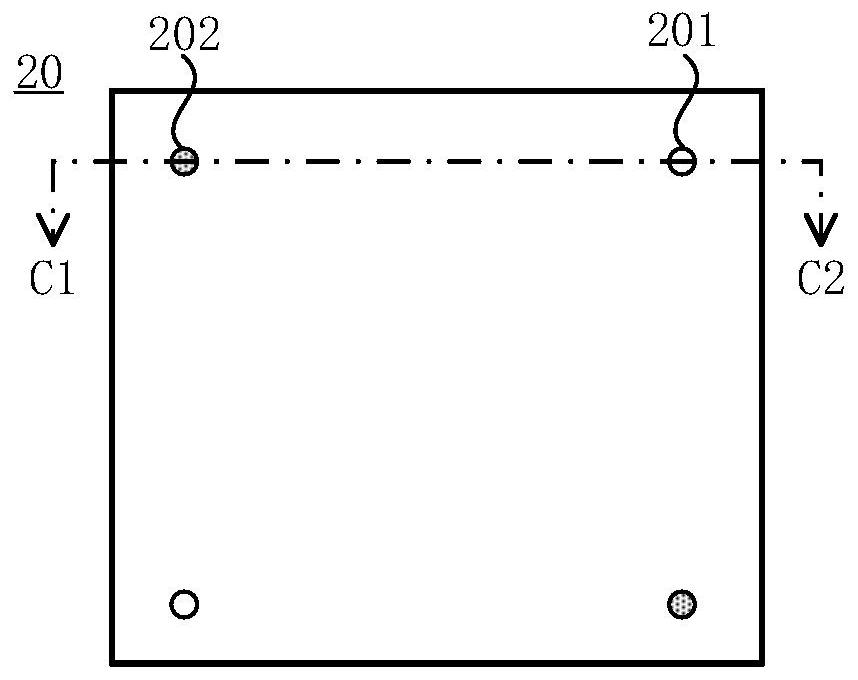

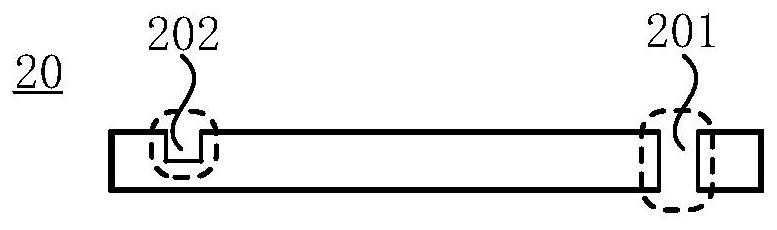

[0056] figure 1 is a schematic structural diagram of a mask alignment device provided by an embodiment of the present invention, figure 2 is a schematic diagram of the planar structure of the mask to be aligned that is aligned by the mask alignment device provided by the embodiment of the present invention, image 3 is along figure 2 Schematic diagram of the cross-sectional structure of C1-C2. refer to Figure 1-Figure 3 , the mask alignment device 10 includes: a detection unit 110, an illumination unit 120 and a workpiece stage unit 130; the illumination unit 120 includes a backlight light source 121, a coaxial light source 122 and a ring light source 123; One side of the unit 110; the side surface of the workpiece table unit 130 away from the backlight light source 121 is used to carry the mask 20 to be aligned; the optical axis of the coaxial light source 122, the optical axis of the ring light source 123 and the central axis of the detection unit 110 are all Coaxial ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com