Automatic putting system of washing machine, washing machine and control method

A technology of automatic feeding and control methods, applied to the control device of washing machines, other washing machines, washing devices, etc., can solve problems such as liquid injection pump leakage, shorten working time, improve washing capacity, and help users experience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

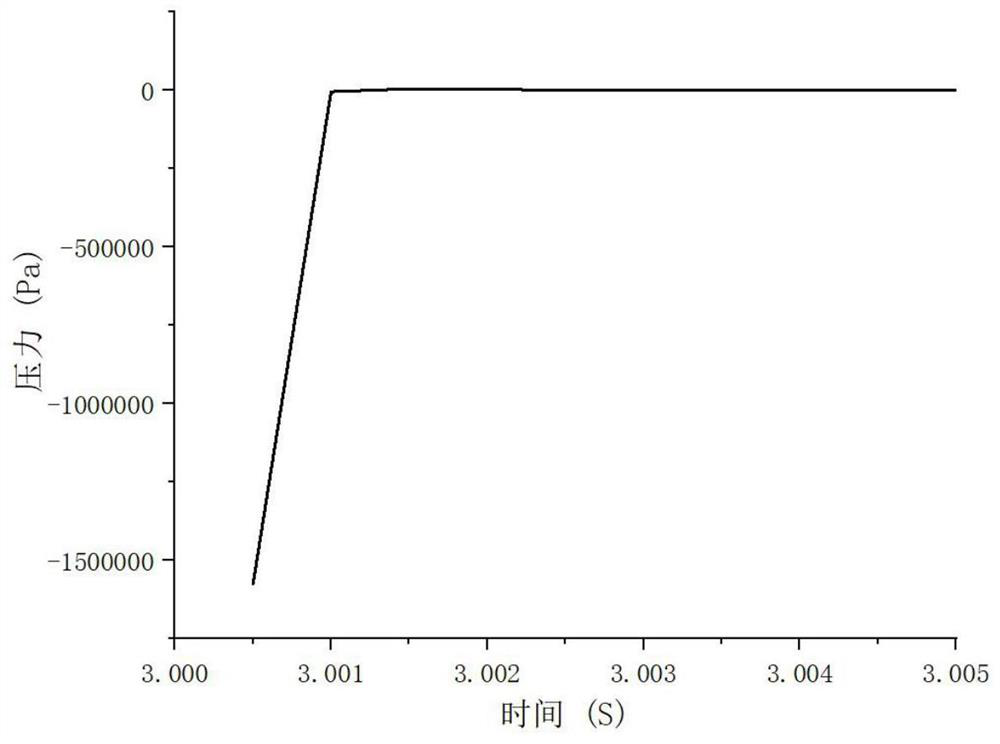

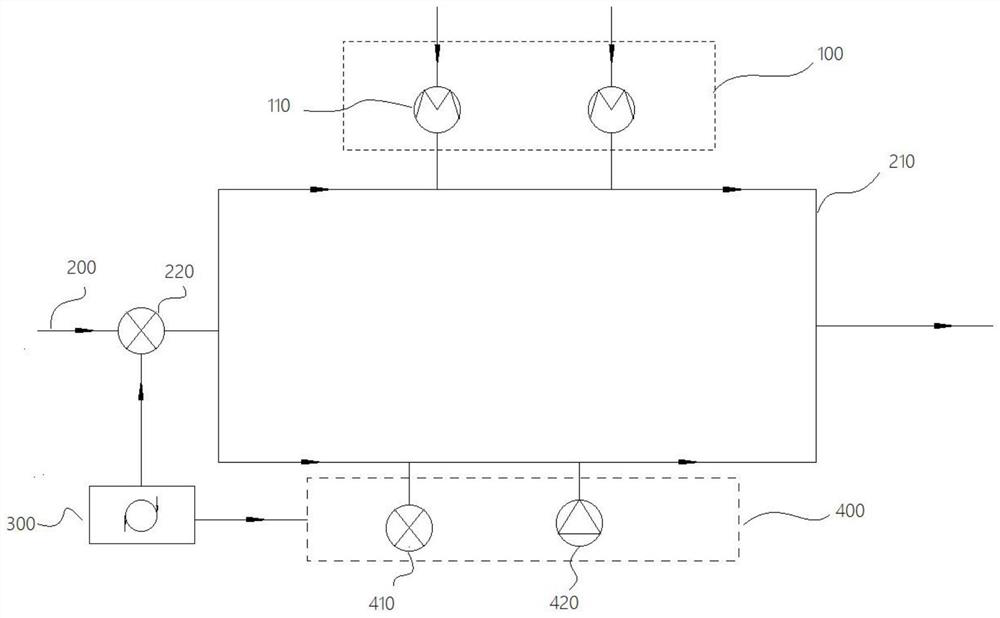

[0037] Embodiment 1. The water inlet flow path 200 is provided with a water inlet valve 220. When the water inlet of the washing machine reaches the set water level, the control system 300 controls the water inlet valve 220 to complete the closing action for a period of time t1 to maintain the pressure value of the public flow path 210 at within a certain pressure range. When the water inlet valve 220 is suddenly closed, a large negative pressure will be generated in the public flow path 210. When the water inlet valve 220 is controlled to complete the closing action after a period of time t1, it can avoid sudden closing and cause excessive pressure fluctuations in the public flow path 210. . The value of t1 lasted is the data obtained through multiple tests before the washing machine leaves the factory and is recorded in the controller of the control system 300. The value of t1 needs to meet the requirement that the water inlet valve 220 completes the closing action without c...

specific Embodiment approach 2

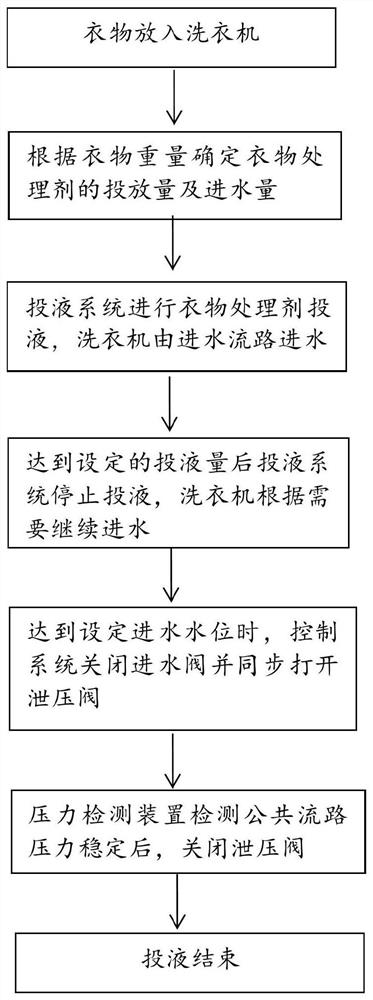

[0039]The automatic dispensing system also includes a voltage stabilizing system 400, which is used to adjust the pressure value of the public flow path 210; The value is within a certain pressure range. The pressure stabilizing system 400 includes a pressure relief valve 410, and the pressure relief valve 410 is arranged on the public flow path 210; when the washing machine is fed with water to a set water level, the control system 300 controls the opening and closing of the pressure relief valve 410 to adjust the pressure of the public flow path 210. The pressure value is within a certain pressure range. The pressure stabilizing system 400 also includes a pressure detection device 420, which is used to detect the pressure value of the public flow path 210; after the pressure relief valve 410 is opened, the control system 300 determines whether to control the pressure relief valve 420 according to the detection result of the pressure detection device 420. Pressure valve 410 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com