Oil pressure online monitoring and testing system

A test system and oil pressure technology, used in fluid pressure actuation system testing, fluid pressure actuation system components, piping systems, etc., can solve problems such as loss, production process interruption, and protection device malfunction, and achieve strong functionality. , the effect of reducing operating costs and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

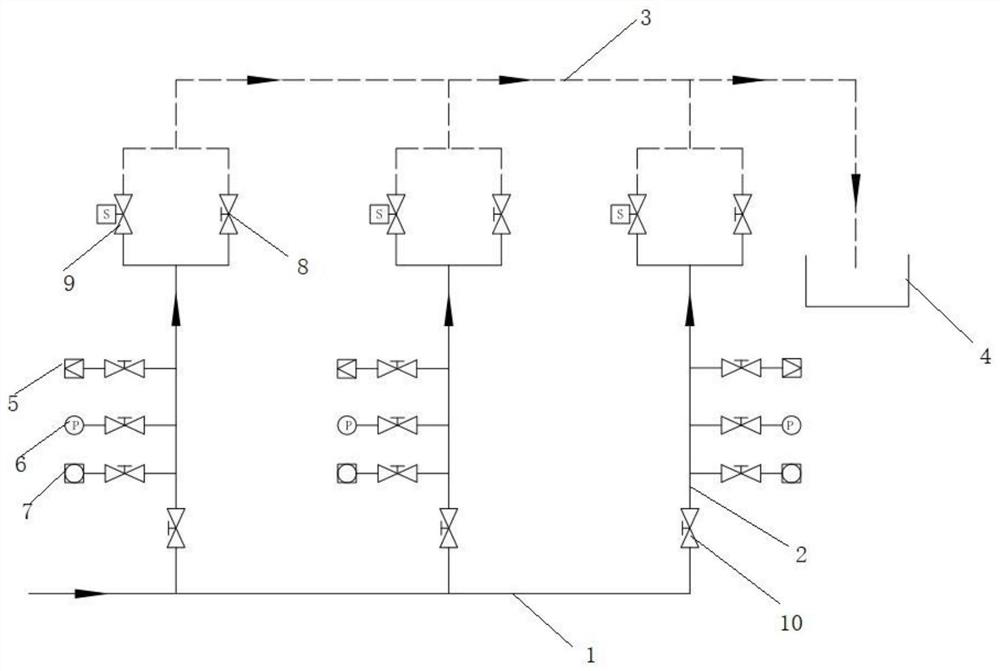

[0016] Attached below figure 1 The present invention is described in further detail.

[0017] An oil pressure online monitoring and testing system, comprising an oil pressure main pipe 1, three source signal pipes 2 connected in parallel to the oil pressure main pipe 1, the other end of the signal pipe 2 is connected to the device under test; the signal pipe 2 After being connected in parallel, it is connected with an oil return pipe 3, and the oil outlet end of the oil return pipe 3 is connected with the oil collection tank 4; Manual valves 8 and remote control valves 9 are connected in parallel, and the remote control valves 9 are connected to the DCS through signal wires.

[0018] During the specific implementation process, the three-way signal tube 2 is taken out from the oil pressure main tube 1, and the oil pressure of the monitored device is judged according to the logic of two out of three in the specific monitoring process, so as to make correct and timely adjustment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com