Device and method for measuring V-shaped separation groove of printed circuit

A printed circuit and measuring device technology, applied in the field of electronic information, can solve the problems of inability to measure the depth of V-shaped separation grooves efficiently, accurately and intuitively, and achieve the effect of high degree of automation and intuitive measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

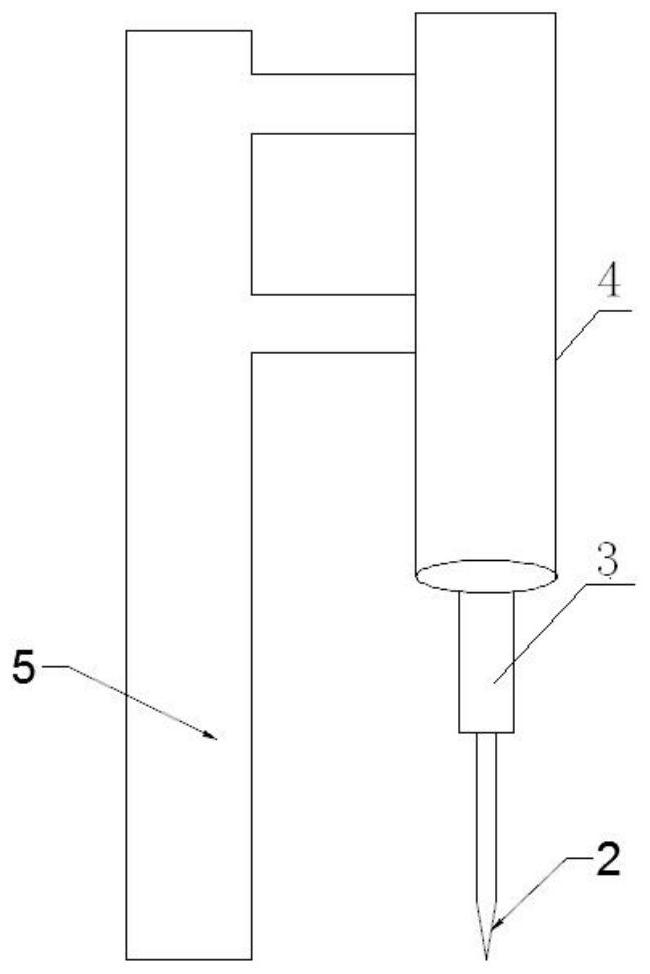

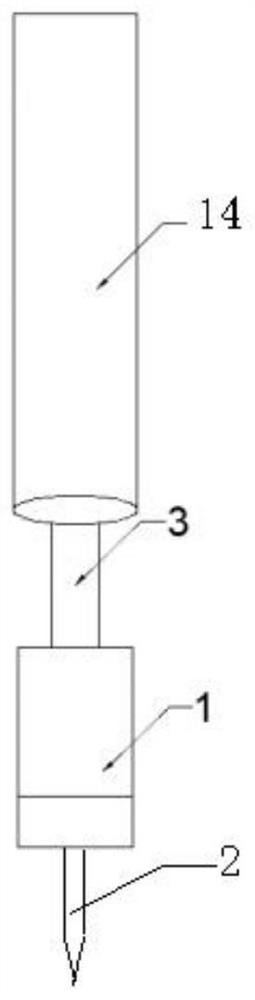

[0021] Such as figure 1 and figure 2 As shown, a measuring device for a V-shaped separation groove of a printed circuit includes a blade 2, a moving rod 3, a linear displacement sensor 4 and a bracket 5, the linear displacement sensor 4 includes a linear displacement processor 14 and a detection head 1, and the bracket 5 is right Connect the linear displacement processor 14, the linear displacement processor 14, the moving rod 3 and the blade 2 are sequentially connected from top to bottom, the blade 2 is connected to the detection head 1; the detection head 1 is electrically connected to the linear displacement processor 14.

[0022] In actual operation, the lower end of the bracket 5 is level with the lower end of the blade 2. During measurement, the lower end of the bracket 5 is close to the surface of the printed circuit board. The moving rod 3 controls the insertion of the blade 2 into the V-shaped separation groove, and the detection head 1 moves with the blade 2. , th...

Embodiment 2

[0025] On the basis of Example 1, the blade 2 is made of tungsten steel. Tungsten steel material has a series of excellent properties such as high hardness, wear resistance, good strength and toughness, heat resistance and corrosion resistance, especially its high hardness and wear resistance, which basically remain unchanged even at a temperature of 500°C , It still has a high hardness at 1000°C, and the blade made of tungsten steel avoids the problem of frequent insertion of the blade during measurement, which will cause wear to the blade, increase the measurement error, and then reduce the measurement accuracy.

[0026] Further, the shape of the lower end of the blade is wedge-shaped. The wedge-shaped structure is simple, it is convenient to insert into the depth of the V-shaped separation groove, the weight of the blade 2 is reduced, and it is beautiful, simple in structure and high in applicability.

[0027] Further, the bevel angle of the blade is 10 degrees, and the we...

Embodiment 3

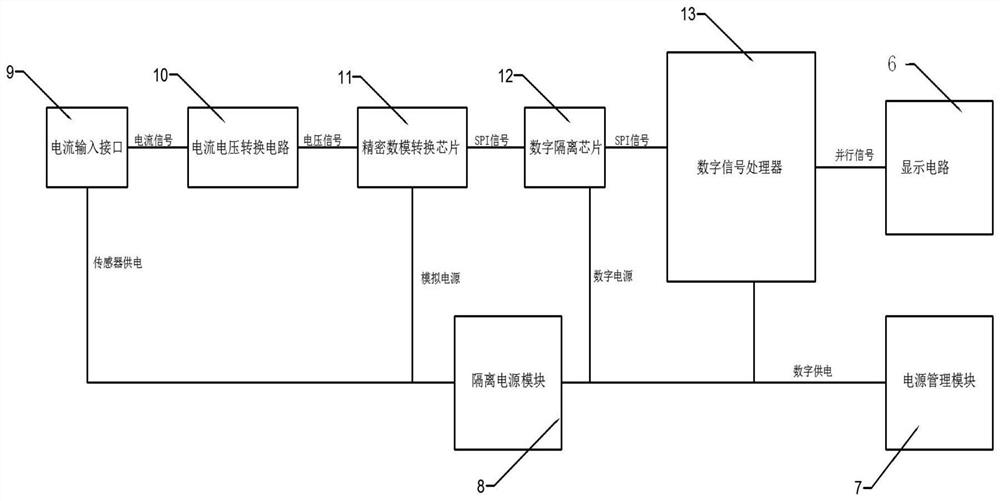

[0029] On the basis of Example 2, such as image 3 As shown, the linear displacement processor 14 includes a power management module 7, an isolated power supply module 8, a current input interface 9, a current-voltage conversion circuit 10, a digital-to-analog conversion chip 11, a digital isolation chip 12, a digital signal processor 13 and a display Circuit 6, the current input interface 9, current-voltage conversion circuit 10, digital-to-analog conversion chip 11, digital isolation chip 12, digital signal processor 13 and display circuit 6 are electrically connected in sequence, and the power management module 7 is electrically connected to the isolated power supply module respectively 8. The current input interface 9, the digital-to-analog conversion chip 11, the digital isolation chip 12 and the digital signal processor 13, and the isolated power supply module 8 are respectively electrically connected to the current input interface 9, the digital-to-analog conversion chip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com