Efficient preheating device for probe card

A preheating device and probe card technology, which is applied in the field of probe card preheating, can solve the problems of low working efficiency of the probe card preheating device, achieve the effects of improving beneficial effects, expanding the scope of use, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

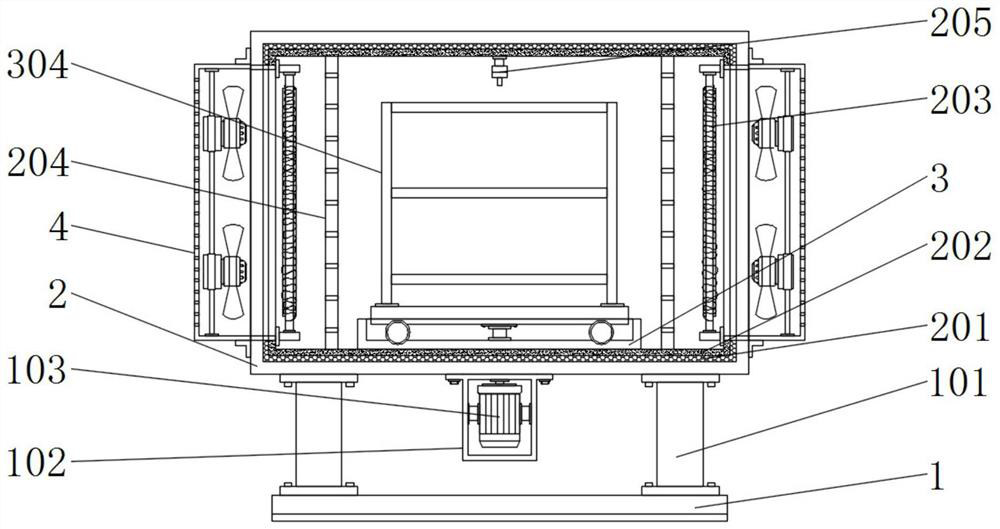

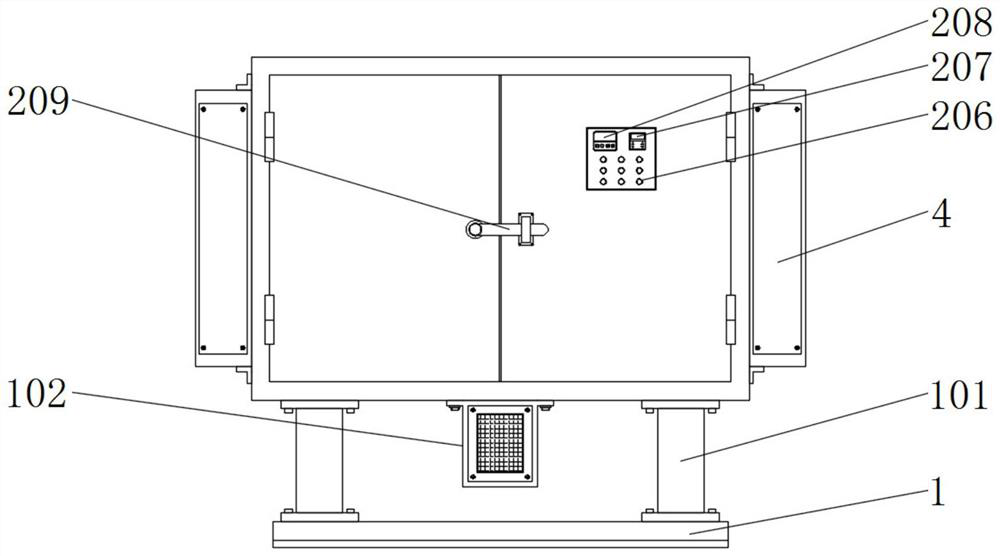

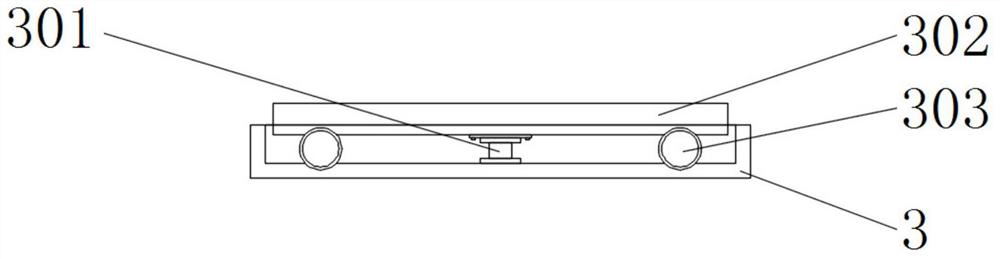

[0053] see Figure 1-4 , an embodiment provided by the present invention: a high-efficiency preheating device for probe cards, including a base 1, a preheating device protection shell 2, a turntable mounting base 3 and a blower fan protection shell 4, and the top of the base 1 is fixedly installed with The preheating device protection shell 2, the base 1 and the preheating device protection shell 2 are fixedly installed through the support frame 101, and the bottom of the base 1 is provided with a rubber protection pad for use;

[0054] The inside of the protective casing 2 of the preheating device is provided with a heat insulating layer 201 and a thermal insulation layer 202 in sequence. Both sides of the protective casing 2 of the preheating device are fixedly installed with resistance heating wires 203, and one side of the resistance heating wires 203 is fixedly installed with a stopper. The plate 204 is used in cooperation with the blowing fan 401, the resistance heating ...

Embodiment 2

[0061] A high-efficiency preheating device for a probe card, the specific implementation method is the same as that of Example 1. The difference lies in that the material of the heat insulation layer (201) is modified polyurethane.

[0062] The raw materials of the modified polyurethane include: in parts by weight, 56 parts of polyester polyol, 18 parts of isocyanate, 7 parts of ethanolamine, 4 parts of oxysilane, 1 part of catalyst and 3 parts of foaming agent.

[0063] The hydroxyl value of the polyester polyol is 204 mg KOH / g, purchased from Shandong Moore Chemical Co., Ltd., the model is 2054.

[0064] The isocyanate is MDI and IPDI, and the weight ratio of MDI and IPDI is 2:3. The CAS number of MDI is 26447-40-5, and the CAS number of IPDI is 4098-71-9.

[0065] The ethanolamine is diethanolamine, triethanolamine and N-tert-butylethanolamine, and the weight ratio of the three is 1.4:1:0.5.

[0066] The raw material of the modified polyurethane also includes 30 parts of...

Embodiment 3

[0077] A high-efficiency preheating device for a probe card, the specific implementation method is the same as that in Example 2. The difference is that the material of the modified polyurethane does not include bisphenol A epoxy resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com