Appearance defect detection method and device for industrial product and storage medium

A technology for appearance defects and industrial products, applied in the field of industrial appearance inspection, can solve the problems of low detection success rate, low detection accuracy, insufficient detection feature extraction, etc., to achieve high-precision detection and improve detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

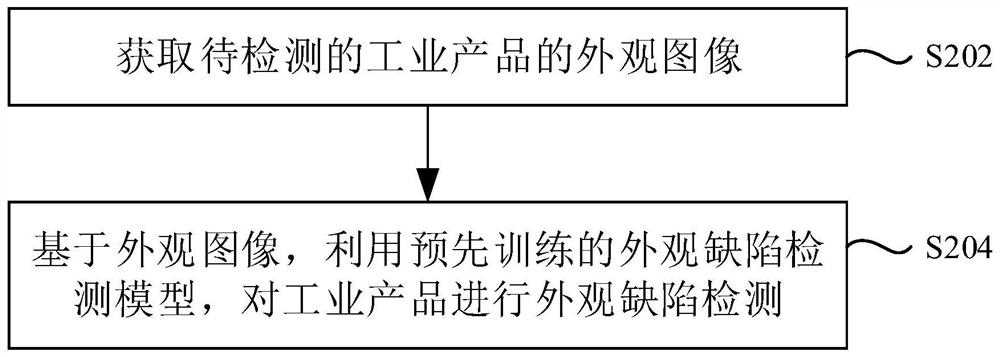

[0024] According to this embodiment, an embodiment of a method for detecting appearance defects of industrial products is provided. It should be noted that the steps shown in the flow charts of the drawings can be executed in a computer system such as a set of computer-executable instructions, Also, although a logical order is shown in the flowcharts, in some cases the steps shown or described may be performed in an order different from that shown or described herein.

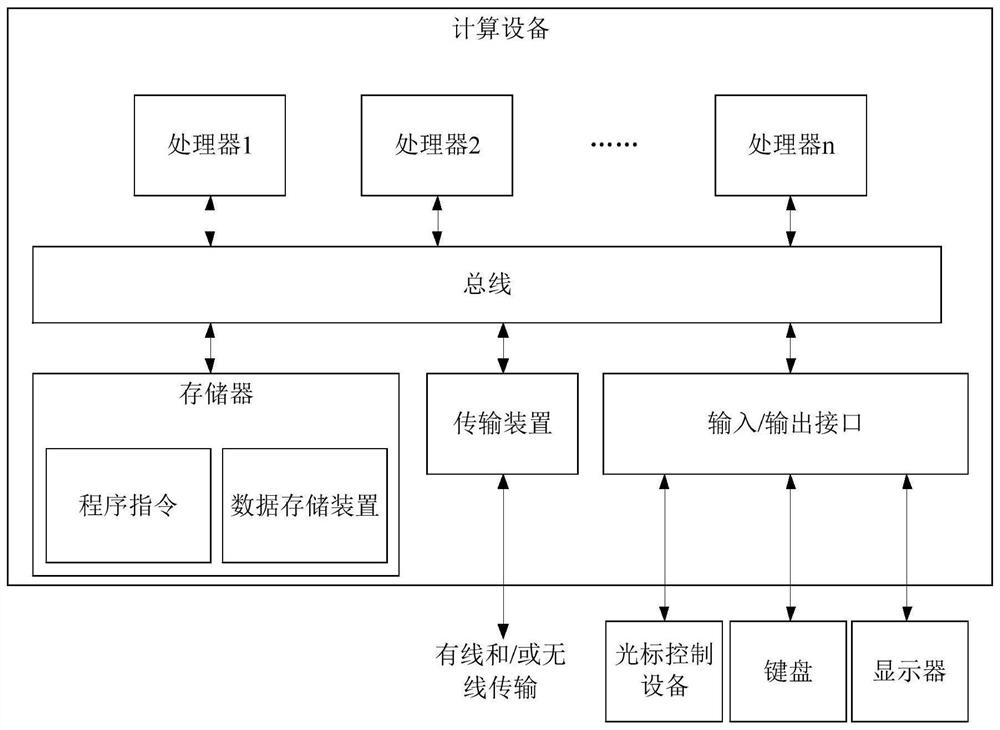

[0025] The method embodiments provided in this embodiment can be executed in a server or similar computing devices. figure 1 A block diagram of a hardware structure of a computing device for implementing a method for detecting an appearance defect of an industrial product is shown. Such as figure 1 As shown, the computing device may include one or more processors (processors may include but not limited to processing devices such as microprocessors MCUs or programmable logic devices FPGAs), memory for storing d...

Embodiment 2

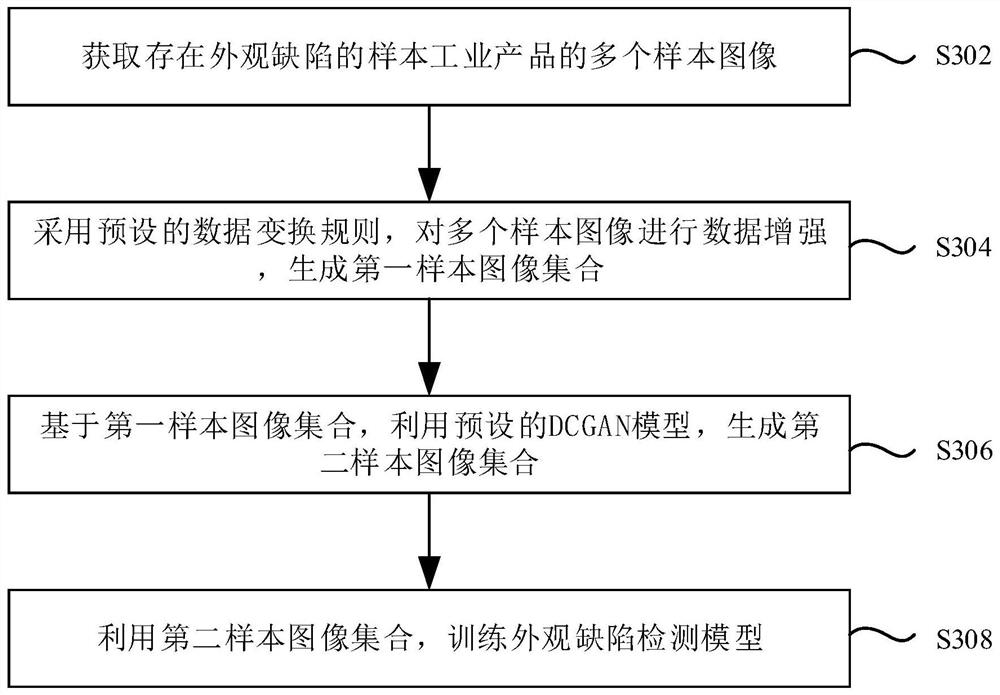

[0123] Figure 6 A device 600 for detecting appearance defects of industrial products according to this embodiment is shown, and the device 600 corresponds to the method according to the first aspect of Embodiment 1. refer to Figure 6 As shown, the device 600 includes: an appearance image acquisition module 610 for obtaining an appearance image of an industrial product to be inspected; an appearance defect detection module 620 for using a pre-trained appearance defect detection model based on the appearance image to detect industrial products Perform appearance defect detection, wherein the appearance defect detection device also includes a training module 630, which is used to train the appearance defect detection model through the following submodules: a sample image acquisition submodule, used to obtain multiple samples of sample industrial products with appearance defects Image; the first generation submodule is used to perform data enhancement on a plurality of sample i...

Embodiment 3

[0132] Figure 7 A device 700 for detecting appearance defects of industrial products according to this embodiment is shown, and the device 700 corresponds to the method according to the first aspect of Embodiment 1. refer to Figure 7 As shown, the device 700 includes: a processor 710; and a memory 720, connected to the processor 710, used to provide the processor 710 with instructions for processing the following processing steps: obtaining an appearance image of the industrial product to be inspected; based on the appearance image , using the pre-trained appearance defect detection model to detect the appearance defects of industrial products, wherein the appearance defect detection model is trained by the following operations: obtaining multiple sample images of sample industrial products with appearance defects; using the preset data transformation The rule is to perform data enhancement on multiple sample images to generate a first sample image set; based on the first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com