Semiconductor device unit, manufacturing method thereof and forming device

A manufacturing method and semiconductor technology, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, transistors, etc., can solve the problem that the entire device loses its function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] A semiconductor device comprising: at least one unit;

[0070] Each unit includes:

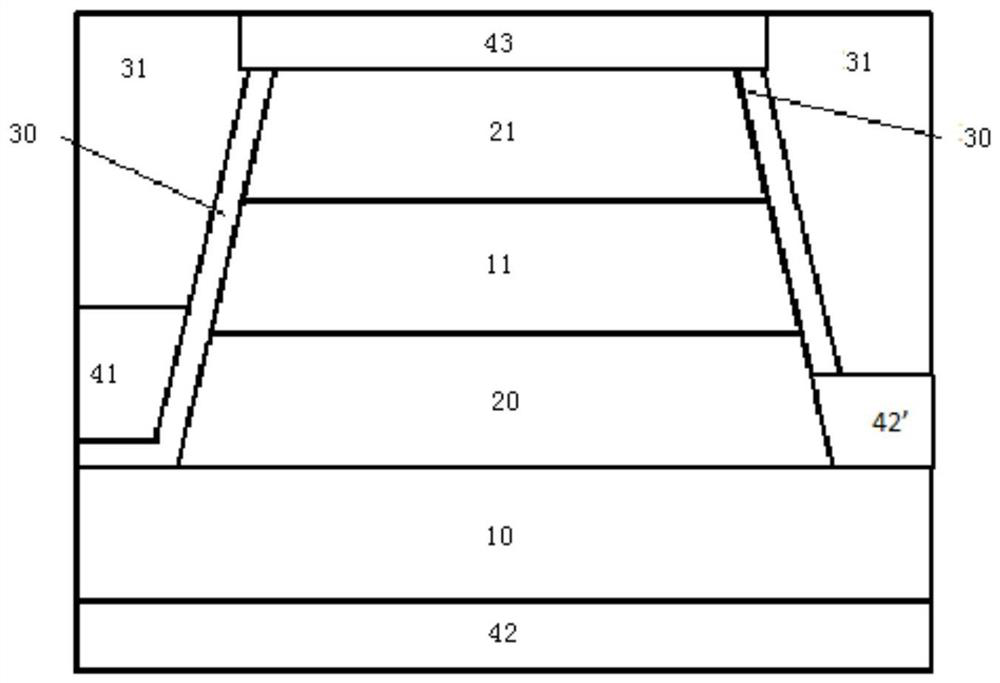

[0071] Such as image 3 As shown, the semiconductor substrate material used as the support layer forms the collector region 10 and has a first doping characteristic;

[0072] The semiconductor layer with the second doping characteristic located on the collector region 10 forms a drift region 20;

[0073] A semiconductor layer with a first doping characteristic located above the drift region 20 forms a well region 11;

[0074] The semiconductor layer with the second doping characteristic located above the well region 11 forms an emitter region 21;

[0075] The insulating layer covering the sides of the collector region 10, the drift region 20, the well region 11, and the emitter region 21 forms an insulating gate 30, which may be silicon oxide or other insulating layers;

[0076] The conductive layer on the insulating gate 30 forms the gate electrode 41, which may be doped polysilico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com