Process for production of high purity isobutylene

An isobutene, high-purity technology, used in separation methods, chemical instruments and methods, purification/separation of hydrocarbons, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

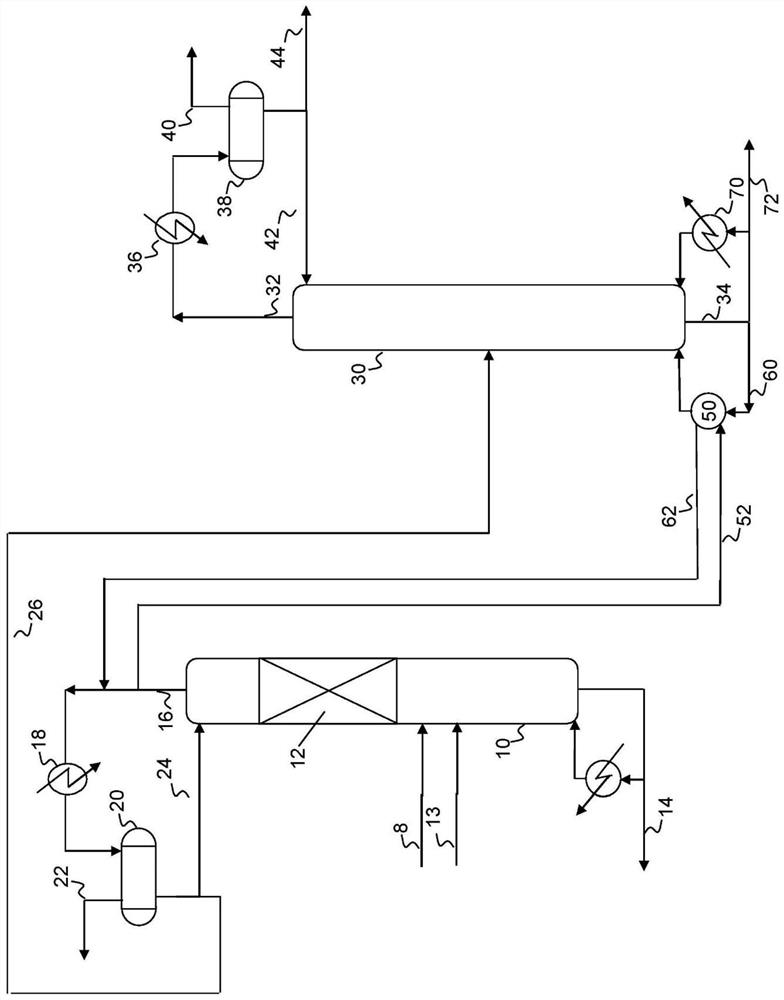

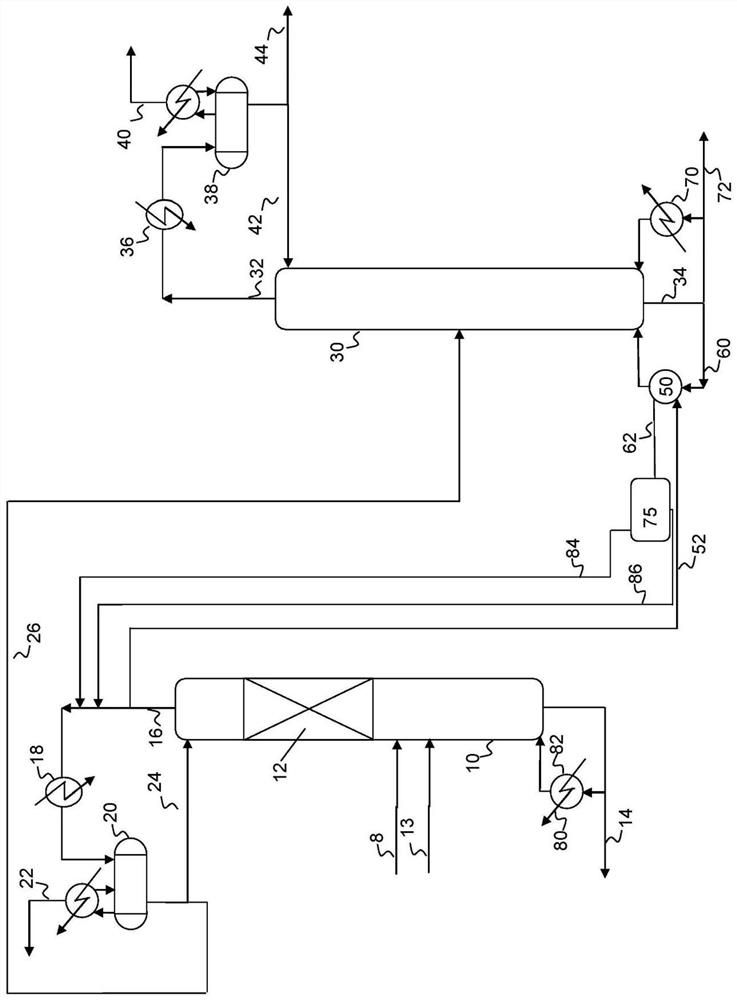

[0013] Embodiments herein relate to a method of producing high purity isobutene (HPIB) through a heat integrated catalytic distillation process.

[0014] The first step in the process involves a catalytic distillation process to separate a stream containing isobutene and isobutane from a stream containing mixed C4, which may contain 1-butene, 2-butene, isobutene, Butane, isobutene, butadiene and n-butane. Catalytic distillation combines distillation of 1-butene to 2-butene and linear hydroisomerization and allows complete separation of all heavier (higher boiling) C4 components from the overhead isobutane plus isobutene stream. This stream is then fed to the second step of the process, which includes a fractionation column to separate high purity (98.0-99.99% by weight) isobutene from isobutane.

[0015] The catalytic distillation process is carried out at elevated pressures much higher than atmospheric pressure as disclosed for example in US6242661 where "atmospheric" pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com