System and method for quick and low noise relay switching operation

A low-noise, relay technology, used in relays, electrical switches, circuits, etc., to solve problems such as inaccuracy and inability to ensure performance consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In the following, preferred methods and systems according to preferred embodiments of the present invention will be described. These exemplary embodiments are given by way of illustration only, and should not be construed in a limiting manner. In describing the drawings, references already introduced and redundant to previously discussed drawings will be omitted.

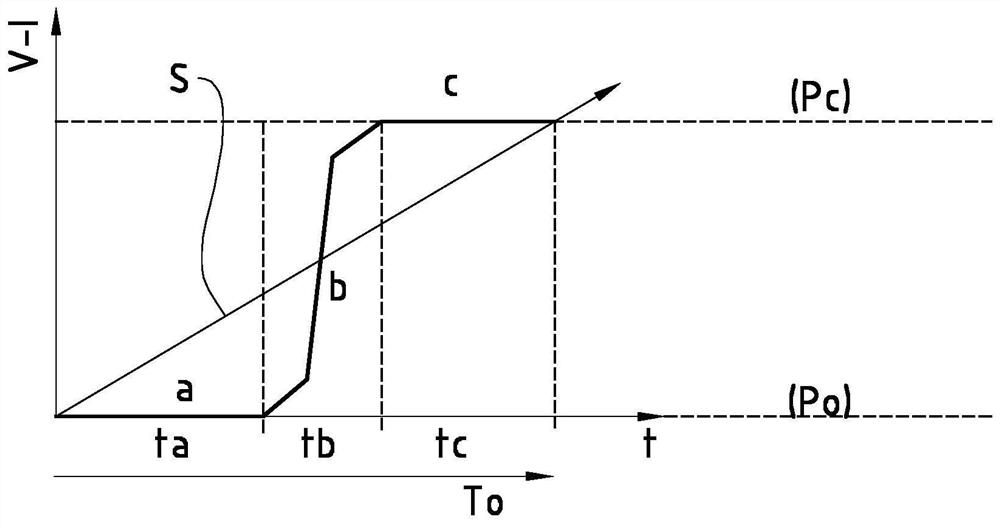

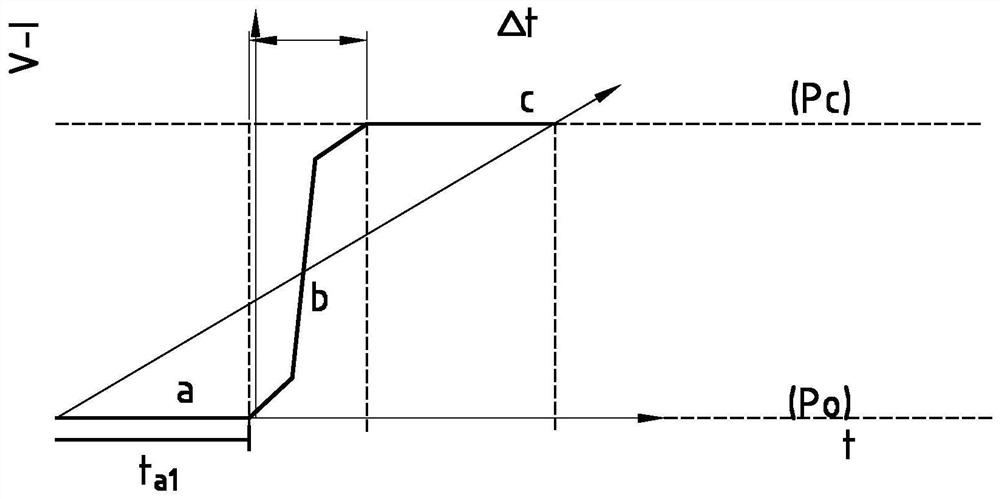

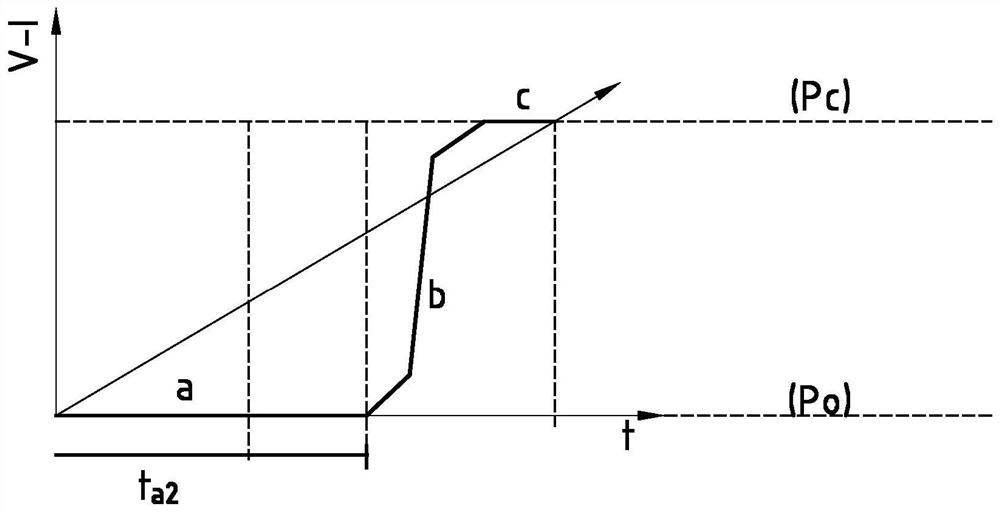

[0046] The method used in the framework of the present invention uses a combination of electromechanical and solid-state relays - also known as hybrid relays - to increase the total number of switches by shaping new types of waveforms to drive the relay coils, and to greatly reduce the Noise and switching relays are switched simultaneously while performing switching in the shortest possible time.

[0047] exist image 3 A preferred system for applying the disclosed method is depicted in , showing a hybrid relay 1 made of an electromechanical part 10 and a solid state relay (SSR) part 11 comprising a TRIAC 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com