Carbon fiber composite material train body forming process for high-speed train and train body

A composite material and high-speed train technology, applied in the field of rail vehicle body, can solve the problems of high requirements on mechanical properties of composite materials, and achieve the effects of improving mechanical properties, high heating efficiency, and reducing internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] refer to figure 1 , the specific embodiment of the present invention is to provide a carbon fiber composite car body forming process for high-speed trains, which is characterized in that the car body forming process includes the following steps:

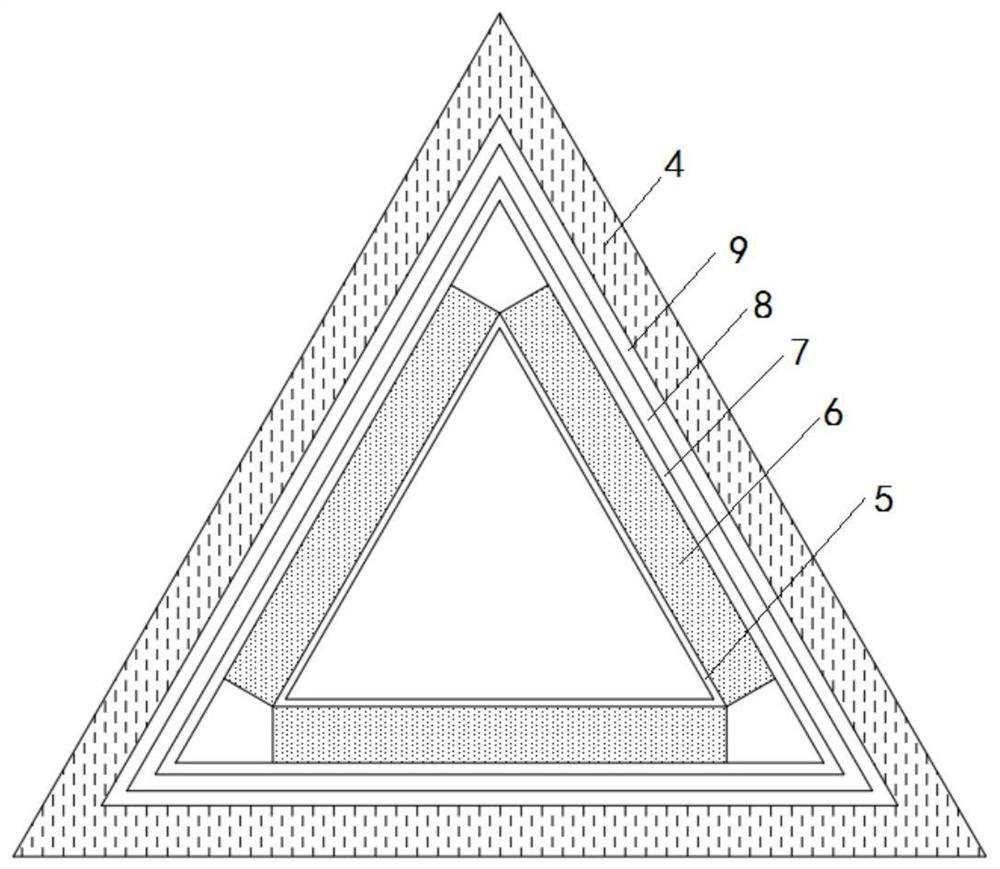

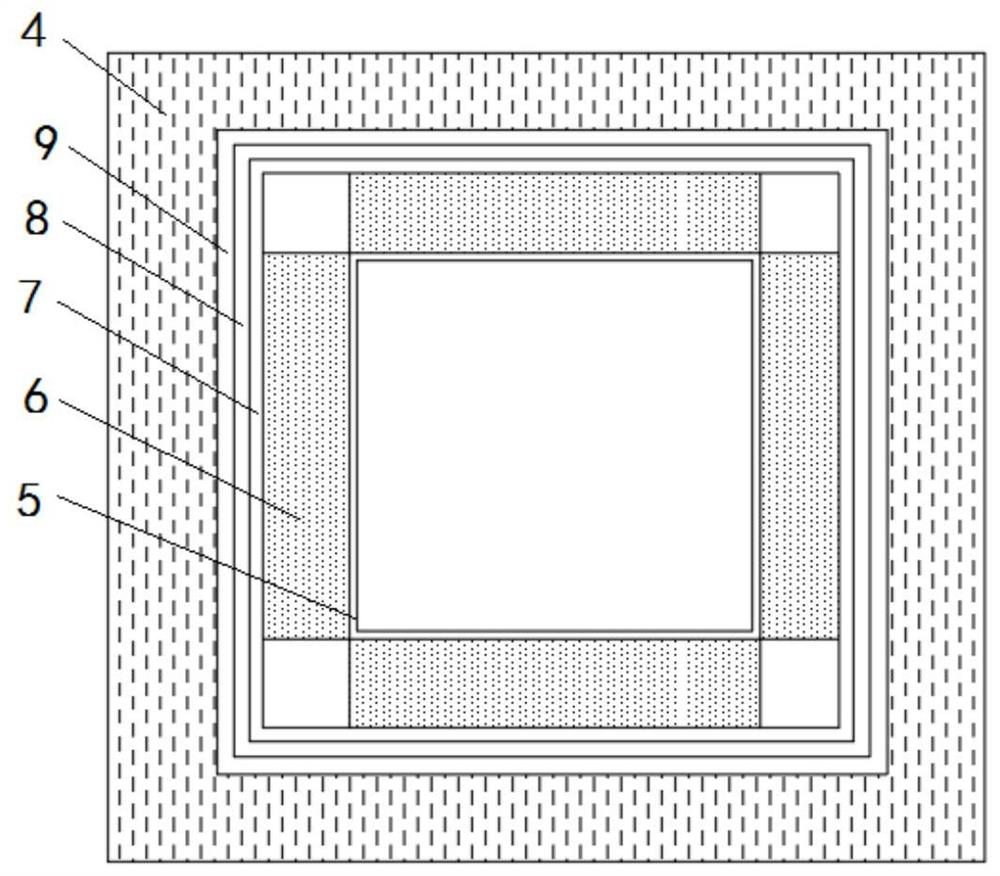

[0034] Step 1, core preforming: a layer of vacuum bag I7, a layer of air felt I8 and a layer of peelable cloth I9 are sequentially attached to the outer surface of the "mouth" or "⊿" shaped flexible core mold 6, the peelable cloth Ⅰ9 Lay carbon fiber prepreg on the outer layer to the required thickness to make a "mouth" or "⊿" shaped core preform 4; wherein the "mouth" or "⊿" shaped flexible core mold 6 is barrel-shaped , consisting of four or three mold plates fixedly combined at both ends, the mold plates can be replaced as required, and the relative position of the mold plates of each core mold can be adjusted;

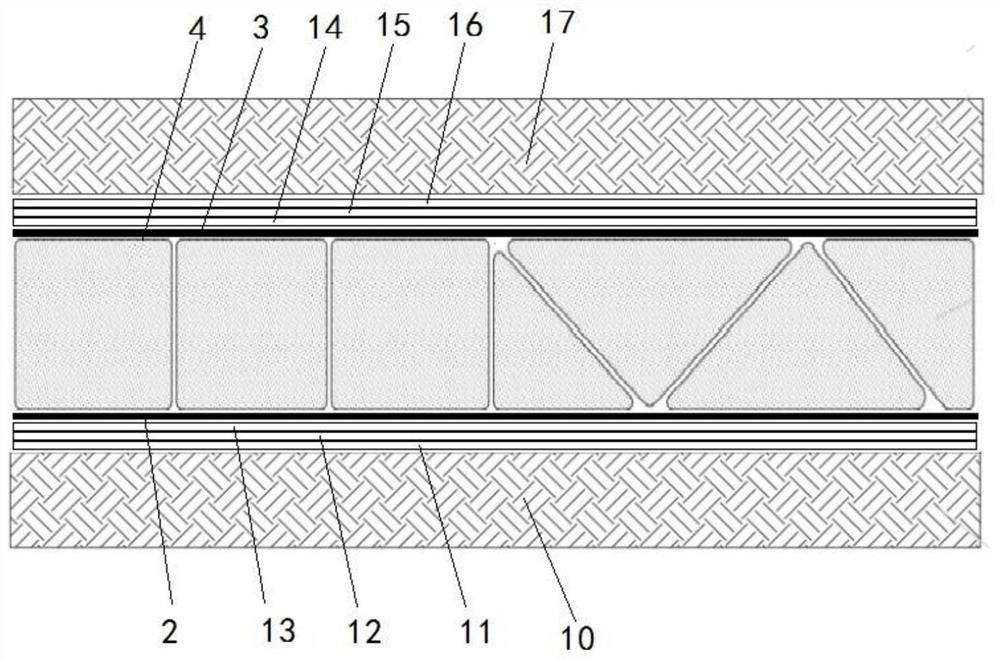

[0035] Step 2, preforming the inner shell of the car body: the inner shell forming mold 10 is constrained by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com