Wide-base wheel, wide-base wheel assembly and electric vehicle

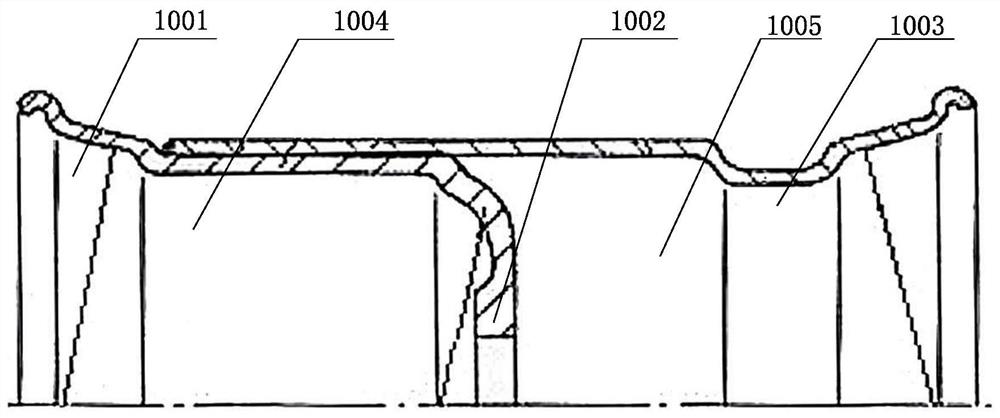

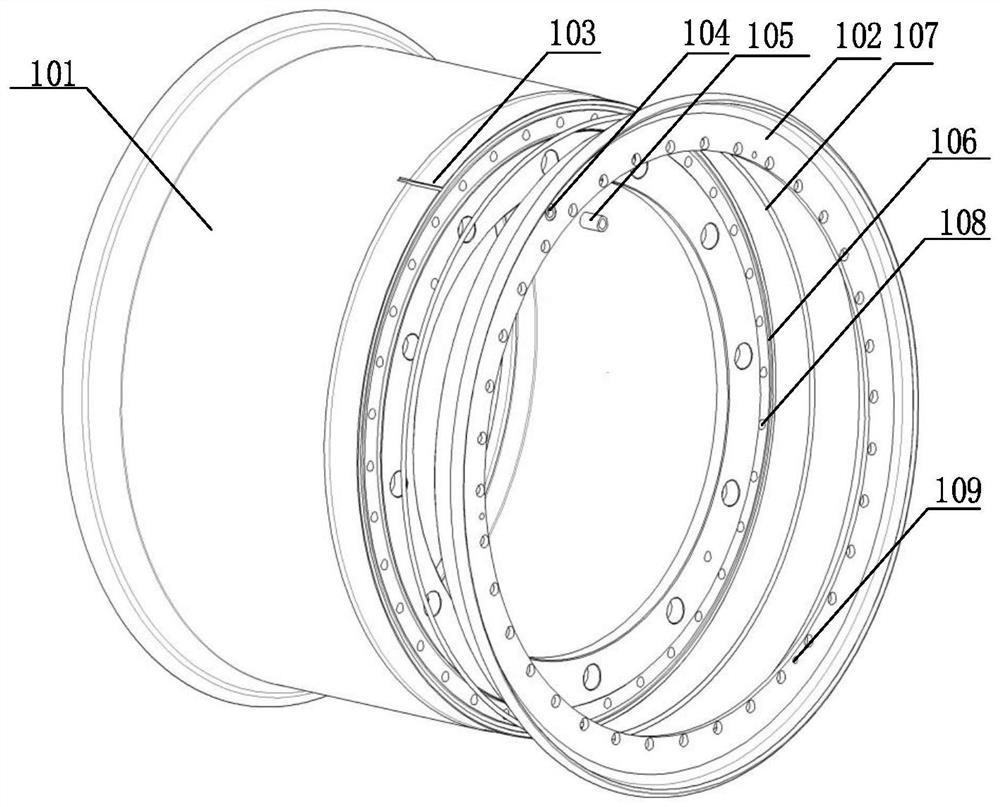

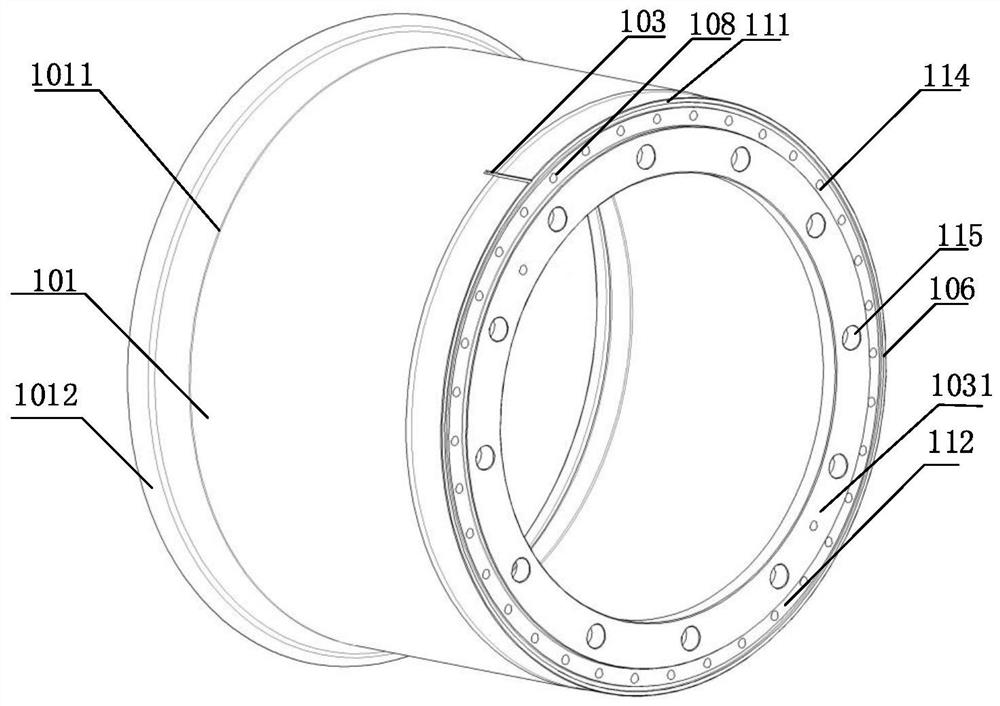

A wheel, wide-based technology, applied in the direction of rims, motion deposition, power devices, etc., can solve the problems of unusable high-power in-wheel motors and limiting vehicle dynamic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present application will be described in detail through three examples below. The specific examples are only for clearly explaining various details of the technical solution in the application, and they do not limit the protection scope of the technical solution in the application. Those skilled in the art may reasonably make changes or additions or subtractions to the technical features in each embodiment according to actual conditions within the scope of understanding of those skilled in the art.

[0033] With the development of electric vehicles, the driving mode of electric vehicles is also changing. Compared with the fuel engine, the structure of the motor is simple, and the installation and maintenance are more convenient. The compactness of the motor makes it an option to combine the wheels with the motor to provide power for the car. This application is an invention created under such circumstances. It should be noted that the motor integrated with the whee...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap