Stringed pagoda pipe disc type automatic discharging storage bin mechanism

A technology of automatic feeding and storage bins, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., which can solve the problems of high cost of re-spinning, label falling off, and many shredded paper scraps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

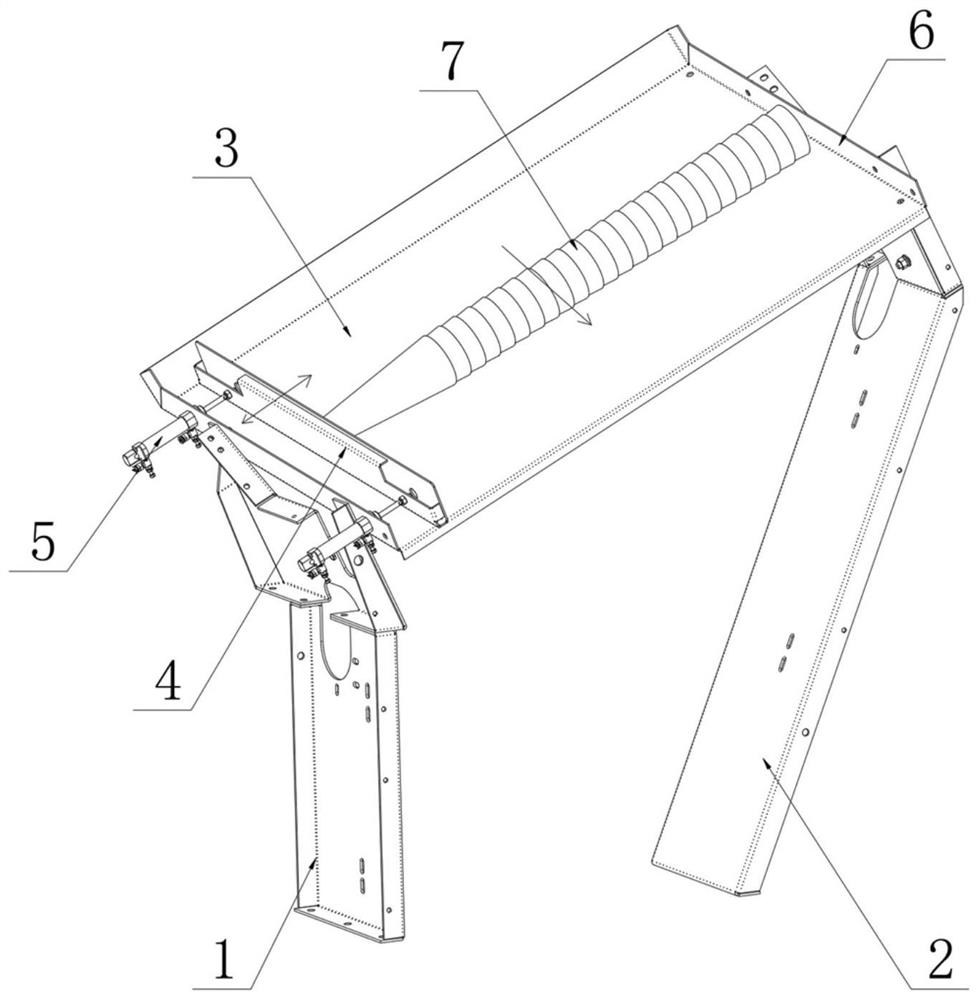

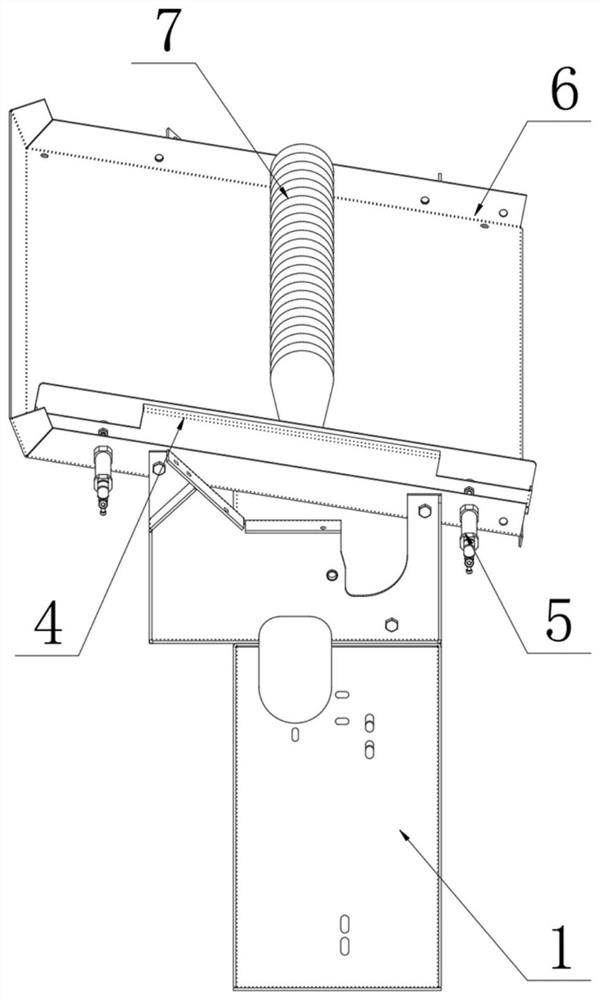

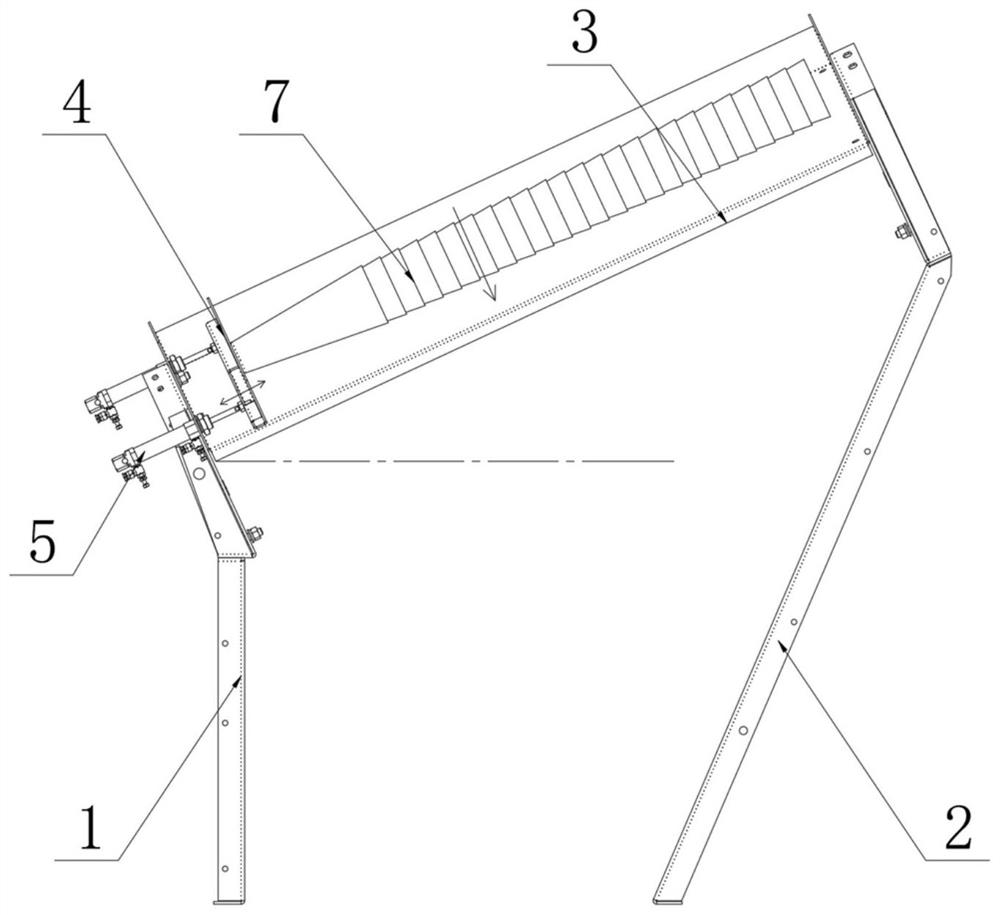

[0038] see Figure 1 to Figure 6 , the present invention relates to a series of pagoda tube slanted plate type automatic unloading and storage bin mechanism, which includes a front bracket 1 and a rear bracket 2, and one or more layers of inclined Type tray 3, the inclined tray 3 is arranged with a low front and a high rear at the same time, and the front side of the inclined tray 3 is provided with a push plate 4 that can be pushed upward intermittently;

[0039] The inclination angle of the front and rear directions of the inclined tray 3 is 20° to 30°, preferably 25°;

[0040] The inclination angle of the left and right directions of the inclined tray 3 is 8-20°, preferably 10°;

[0041] The multi-layer inclined tray 3 is arranged up and down, and the feed side of the inclined tray 3 of the next layer (the higher side in the left-right di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com