High-precision and heavy-load three-roller cold rolling mill

A high-precision, cold-rolling mill technology, applied in the direction of metal rolling stands, metal rolling mill stands, and driving devices for metal rolling mills, can solve the problems of reduced rolling precision, roll deflection, and insufficient rigidity. Achieve the effects of reducing longitudinal tensile stress, reducing longitudinal speed difference and improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to further illustrate the technical solution of the present invention, the present invention will be further described below through examples.

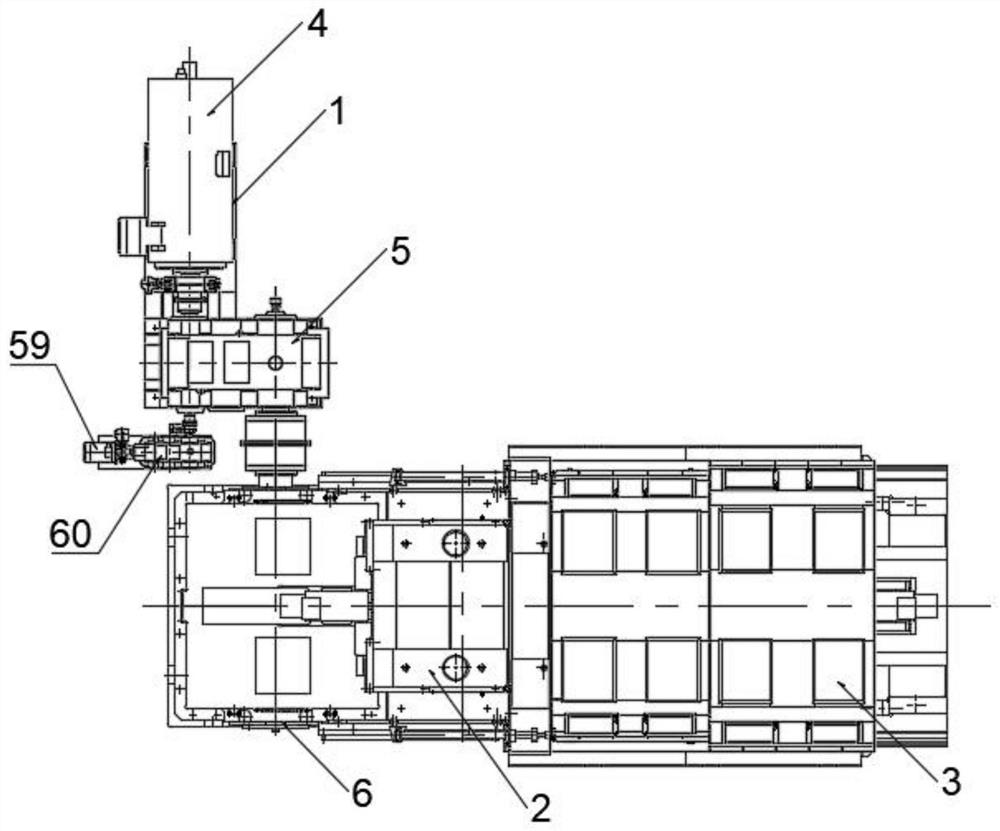

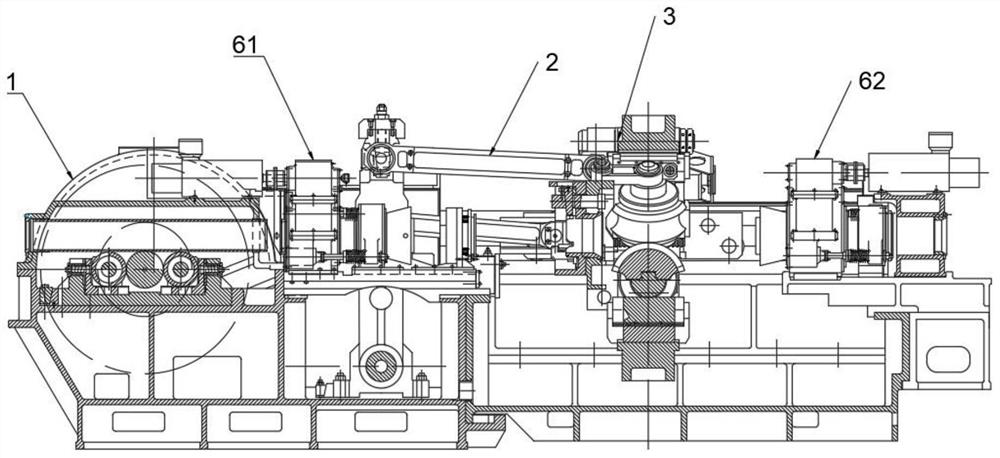

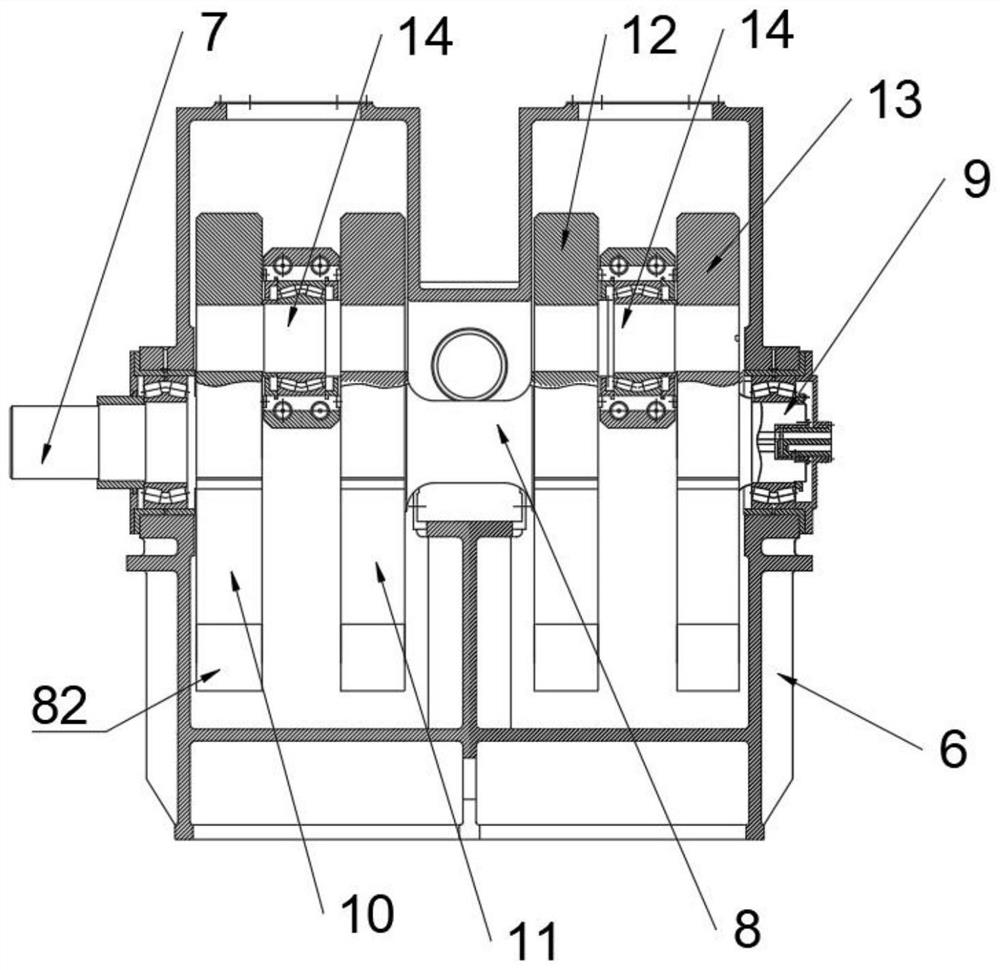

[0053] Such as Figure 1 to Figure 28 As shown, a high-precision, heavy-duty three-roll cold rolling mill includes a transmission mechanism 1, a connecting rod mechanism 2 and a rolling host 3;

[0054] The transmission mechanism 1 includes a main motor 4, a final reducer 5, a transmission mounting frame 6, a No. 1 transmission main shaft 7, a No. 2 transmission main shaft 8, a No. 3 transmission main shaft 9, an energy supplement motor 59 and an energy supplement speed reducer 60. The output shaft of the main motor 4 is connected with the input shaft of the final reducer 5, the output shaft of the final reducer 5 is connected with the No. 1 transmission main shaft 7, and the output shaft of the energy supplementary motor 59 is connected with the energy supplementary motor 59. The input shaft of the speed reducer 60 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com