A support structure for the sintering process of large-scale reaction-sintered silicon carbide

A technology of sintered silicon carbide and sintering process, which is used in charging support, furnace, lighting and heating equipment, etc., can solve the problems of waste reaction sintered silicon carbide products, large body weight, and green body cracking, etc., to avoid rolling, realize Free expansion and contraction, the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

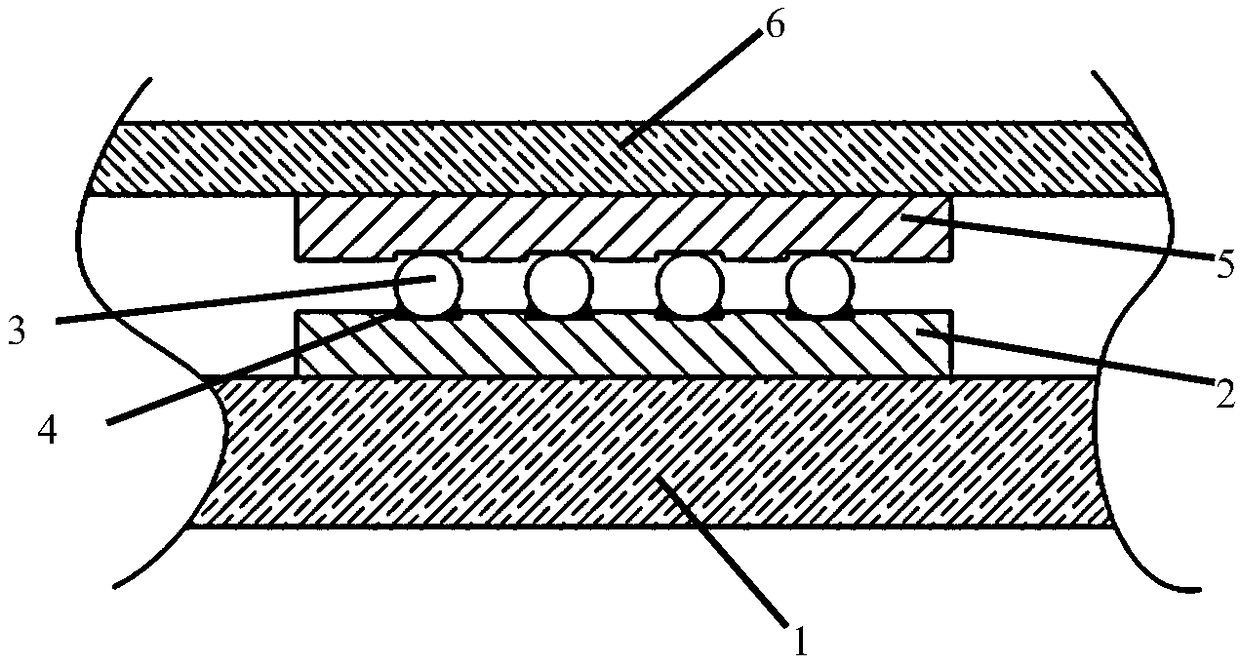

[0018] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments, wherein the methods are conventional methods unless otherwise specified, and the raw materials can be obtained from open commercial channels unless otherwise specified.

[0019] When sintering a non-solid cylindrical preform with a diameter of 2m and a weight of 200kg:

[0020] (1) Take 20 high-strength graphite plates of 300mm×300mm×30mm, and the parallelism of the two planes of each graphite plate is not greater than 0.05mm;

[0021] Mill out three rows and three rows of 9 Φ40mm counters in 12 of the graphite plates, the depth of the counters is 4mm, and the relative positions of the counters on each graphite plate are the same on the graphite plate;

[0022] Three rows and three rows of 9 Φ30mm counters in total are milled on 6 of the graphite plates, the depth of the counters is 4mm, and the relative positions of the counters on each graphit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com