Capacitance detection circuit, touch chip and electronic equipment

A capacitance detection and capacitance detection technology, applied in electronic switches, electrical components, electrical digital data processing, etc., can solve the problems of low sensitivity, small capacitance change, and circuit noise flooding, etc. The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Implementing any technical solution of the embodiments of the present application does not necessarily need to achieve all the above advantages at the same time.

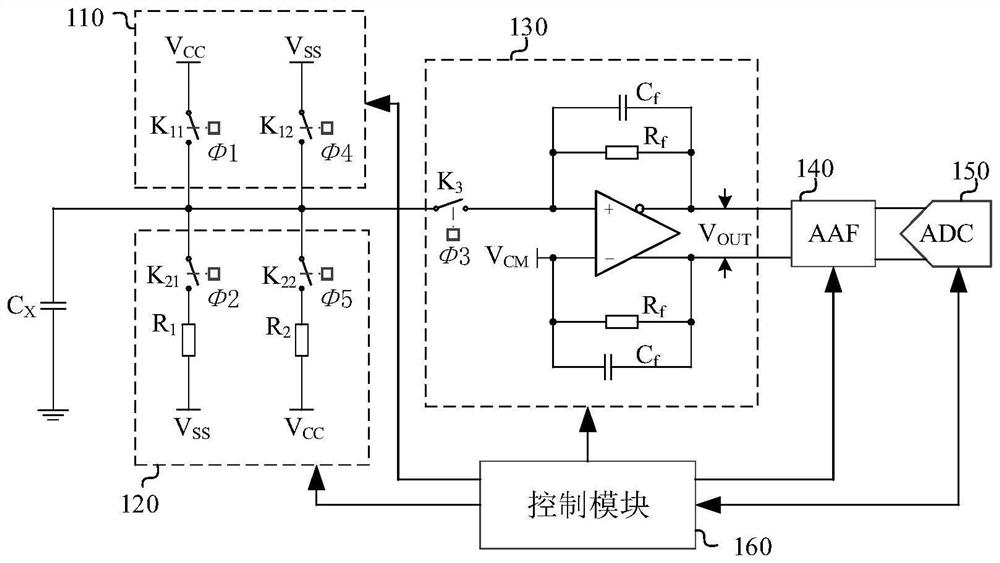

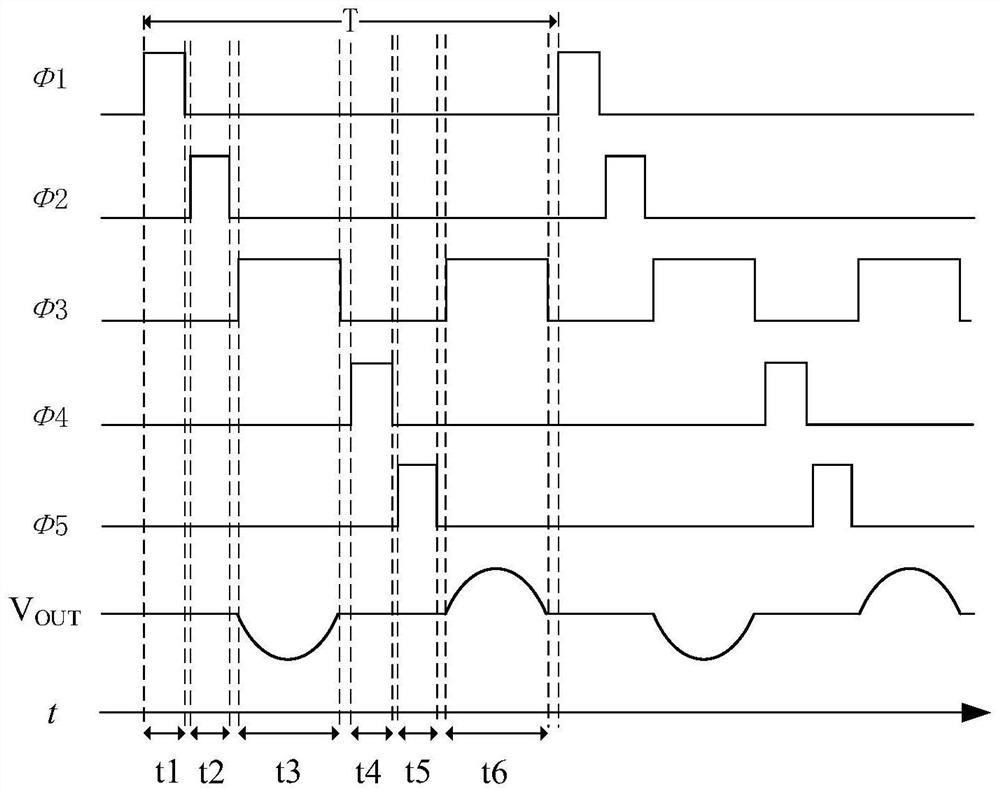

[0051] In the following technical solutions provided by the embodiments of the present application, since the capacitance detection circuit includes: a control module, a driving module, an offsetting module, and a charge transfer module, the driving module is configured to pass the first charging branch under the control of the control module. The detection capacitor is forwardly charged through the second charging branch, or the detection capacitor is reversely charged through the second charging branch; the offsetting module is used to charge the detection capacitor through the first offsetting branch under the control of the control module. The detection capacitor performs basic capacitance cancellation processing, or, under the control of the control module, performs the basic capacitance cancellation proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com