Fabric-contact device, system, in particular heating system for a motor vehicle, and method for producing such a system

A technology of contact devices and fabrics, applied in heating elements, electric heating devices, vehicle connectors, etc., can solve problems such as complicated welding operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

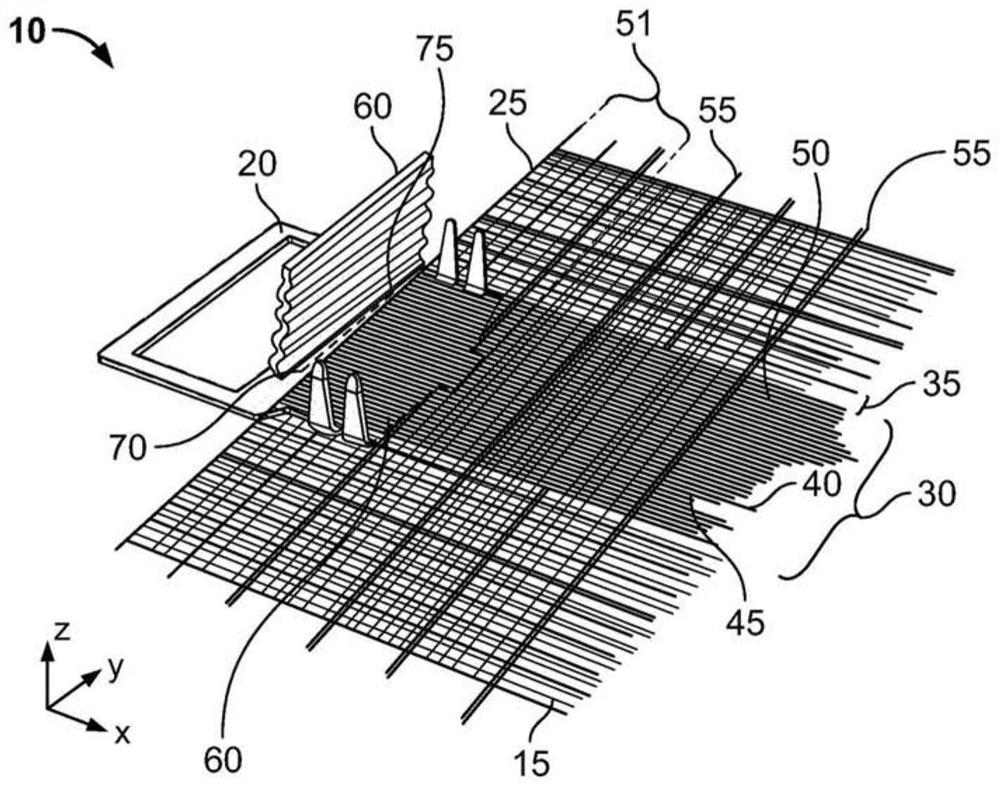

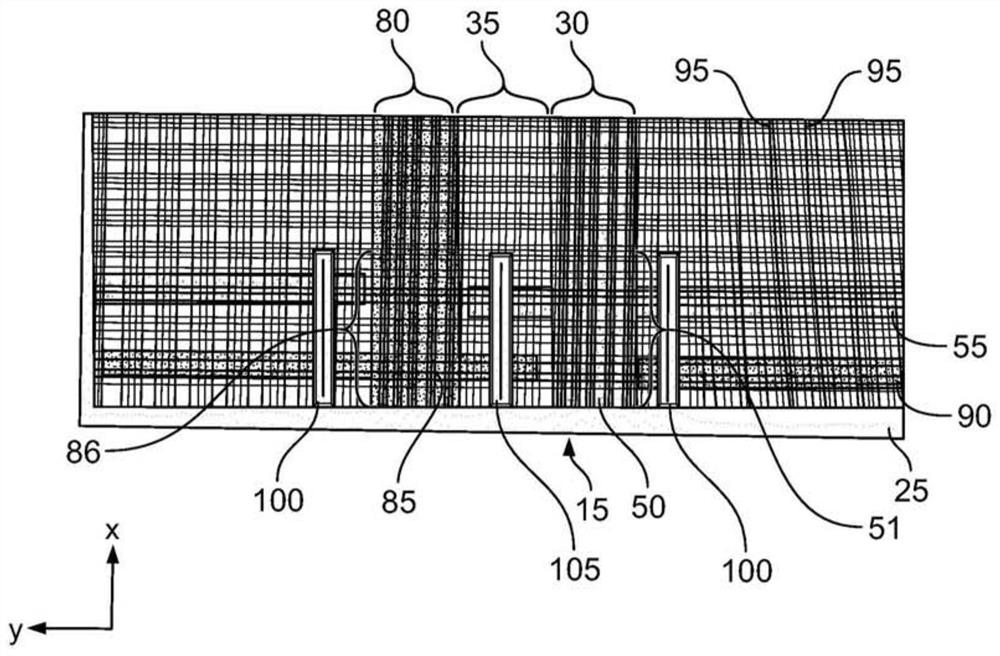

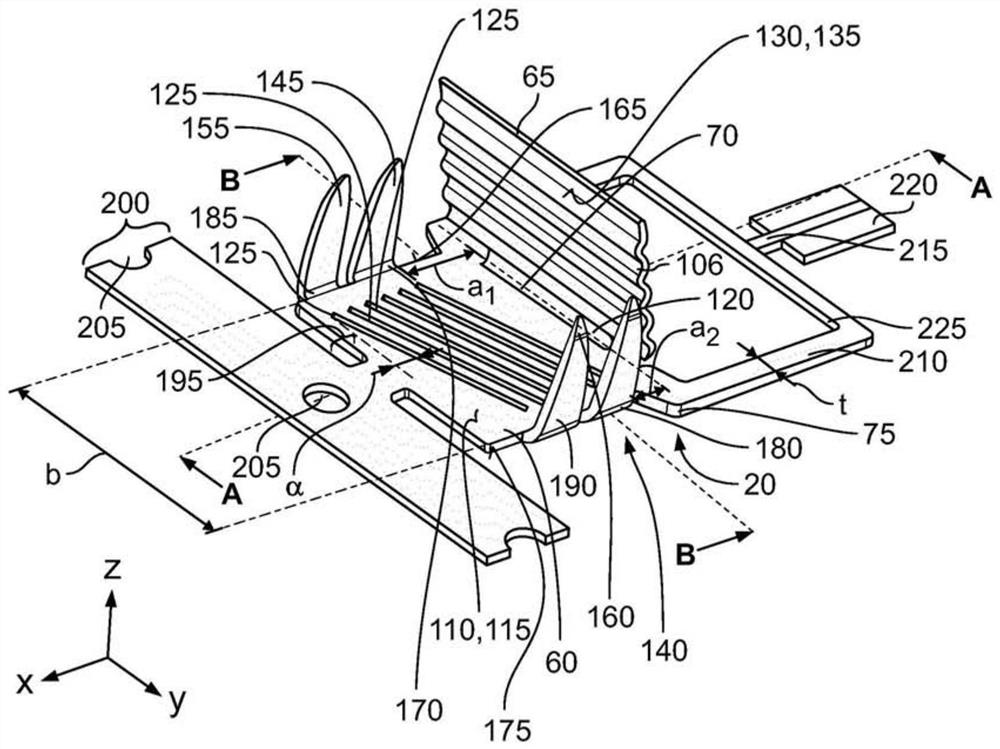

[0043] In the following figures, reference is made to a coordinate system to facilitate understanding. In this case, the coordinate system includes an x-axis (longitudinal direction), a y-axis (lateral direction), and a z-axis (vertical direction). The coordinate system is formed as a right-handed system, for example.

[0044] figure 1 A cross-sectional view of a perspective view of system 10 is shown.

[0045] System 10 may be formed as a heating system for a motor vehicle, in particular seat heating. The system 10 has a fabric 15 and a fabric contacting device 20 . The fabric 15 has an edge 25 which bounds the fabric 15 . In this embodiment, the edge 25 extends in the y-direction as an example. The fabric 15 also includes a first fabric portion 30 and at least one second fabric portion 35 .

[0046] The first textile part 30 and the second textile part 35 in this case extend parallel to each other and, in this embodiment, for example in the longitudinal direction. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com