Floor cleaning machine water level alarm control method and system

A technology of water level alarm and control method, applied in the direction of cleaning carpets, floors, machine parts, etc., can solve problems such as poor user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

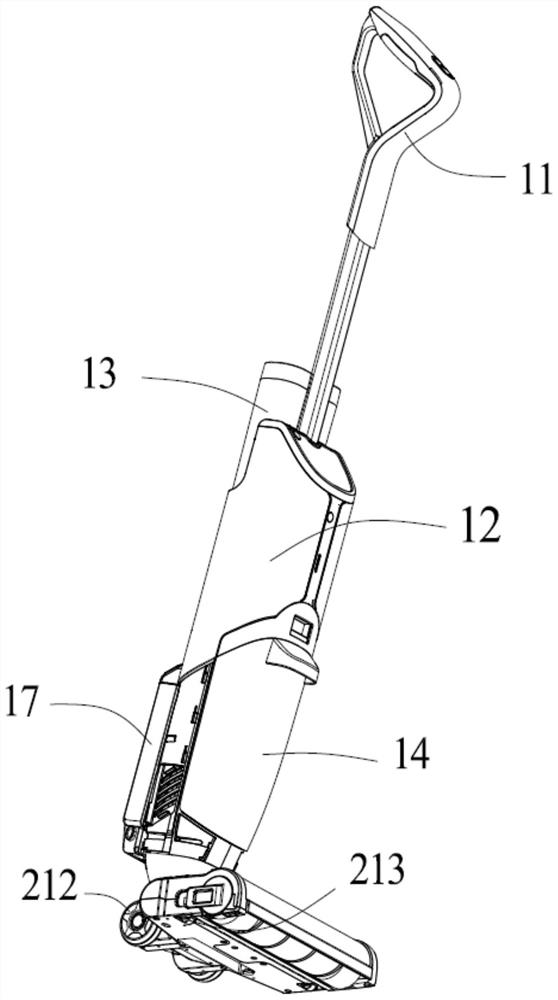

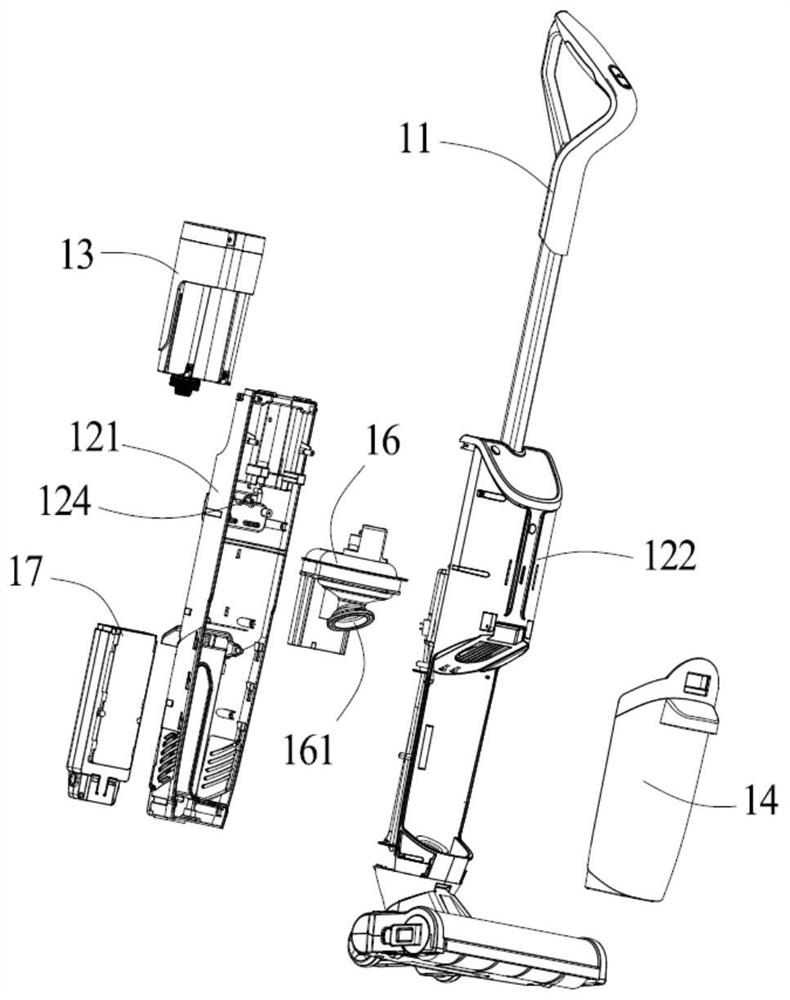

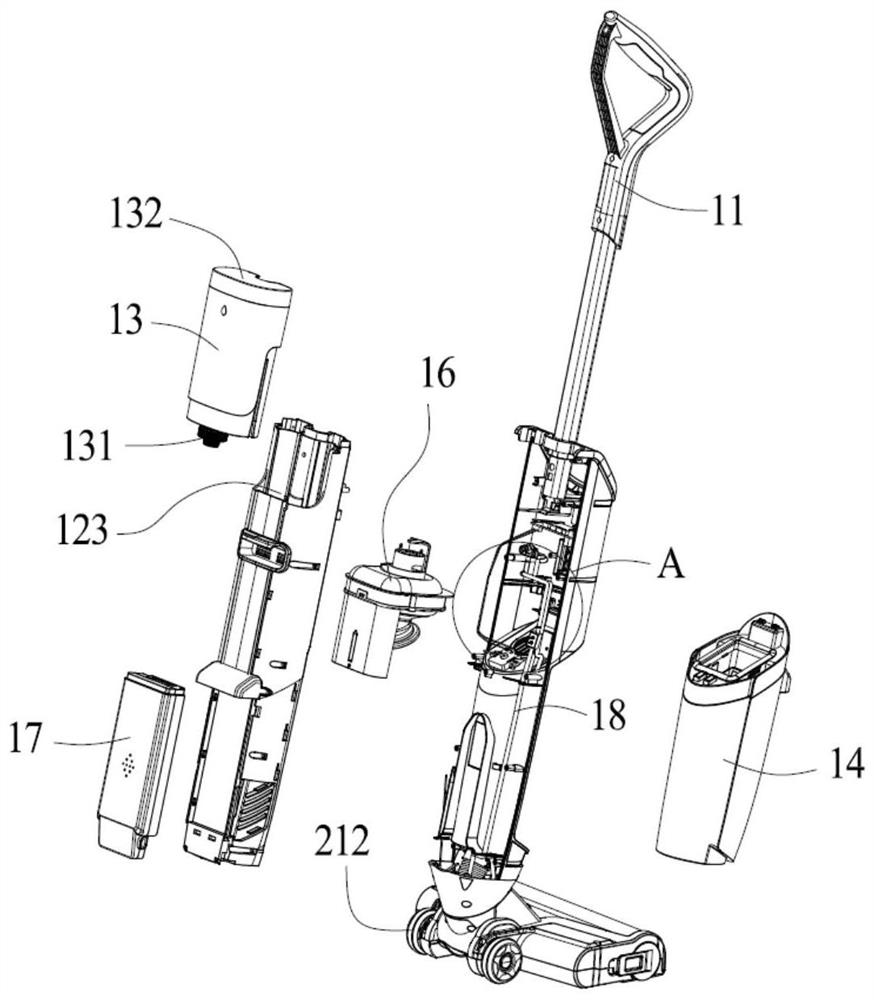

[0039] Such as Figures 1 to 8 As shown in , this embodiment is a floor washing machine. The floor washing machine includes a hand-held part and a base main unit. The supernatant water tank 13, the dirty water tank 14, the main control board 15, the fan unit 16 and the battery 17, and the housing include a front shell 121 and a rear shell 122 assembled with each other.

[0040] The base host includes a base 21 and an upper cover 22 installed on the base, an adapter 23, a water pump 24 and a roller brush mechanism, and the lower end of the rear shell of the hand-held part is connected with the adapter of the base.

[0041] The clean water tank 13 is detachably installed on the front shell 121, and the clean water tank 13 is equipped with a clean water tank cover 132 that can be opened for easy addition of clean water. The outlet 131 at the lower end of the tank is connected to a clean water joint 124 of the front shell, the clean water joint 124 is connected to the upper end o...

Embodiment 2

[0052] In the second embodiment, based on the structure of the washing machine in the first embodiment above, a water level alarm control method for the washing machine is proposed, including:

[0053] A detection component is installed on the outlet pipeline of the clean water tank to detect whether there is clean water in the water outlet pipeline; the detection component transmits the detected induction signal to the main control board; the main control board receives the detected induction signal, judges whether there is clean water, If the result of continuous judgment within the set time is that there is no clear water, an alarm signal will be given.

[0054] After the alarm signal is given, the main control board controls the washing machine to stop working and enter the standby state, and at the same time, an alarm sound is generated or a prompt message is generated on the display screen.

[0055] The preset time is 3 to 10 seconds, preferably 5 seconds. The problem of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com