Long-service-life steam engine delaying incrustation stacking and application method of long-service-life steam engine

A technology of steam engine and scale, applied in the field of steam engine, can solve the problems of electric heating tube surface temperature rising, affecting accuracy, difficult to remove sediment, etc., to achieve the effect of ensuring long-term stable work, prolonging service life, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

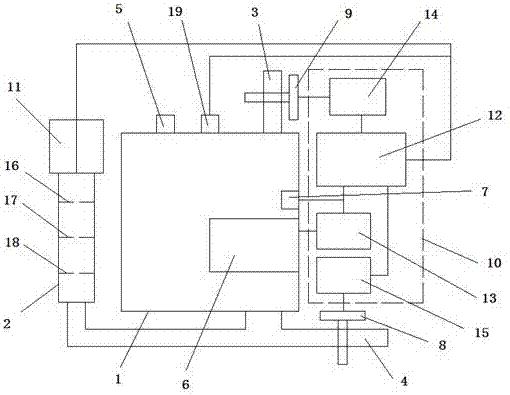

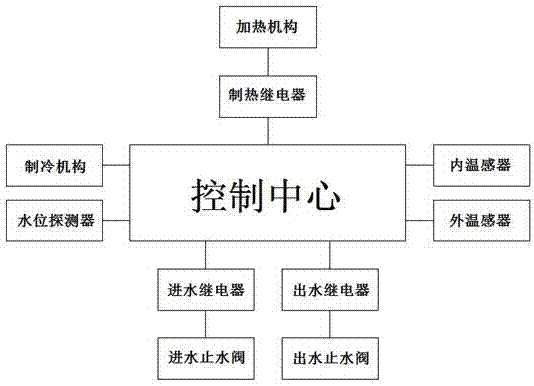

[0038] Such as Figure 1-Figure 2As shown, a steam engine with high service life that delays the accumulation of scale includes a casing 1 and a water level detector 2. The casing 1 is provided with a water inlet 3, a water outlet 4 and a steam outlet 5. Inside the casing 1 A heating mechanism 6 and an internal temperature sensor 7 are also provided. The lower end of the water level detector 2 is connected to the water outlet 4 through a pipeline and forms a waterway connection with the inside of the box body 1. The upper end of the water level detector 2 is provided with an upper connecting pipe 20 and The upper part of the box body 1 is connected to form a gas passage, the end of the water outlet 4 is provided with a water outlet stop valve 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com