Cooling device in liquid sorbitol production process

A production process and cooling device technology, applied in mixers with rotary stirring devices, transportation and packaging, separation/purification of hydroxyl compounds, etc., can solve the problem of slow cooling speed of sorbitol, unusable sorbitol, slow cooling speed, etc. problem, to achieve the effect of speeding up heat dissipation, speeding up cooling, and facilitating stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

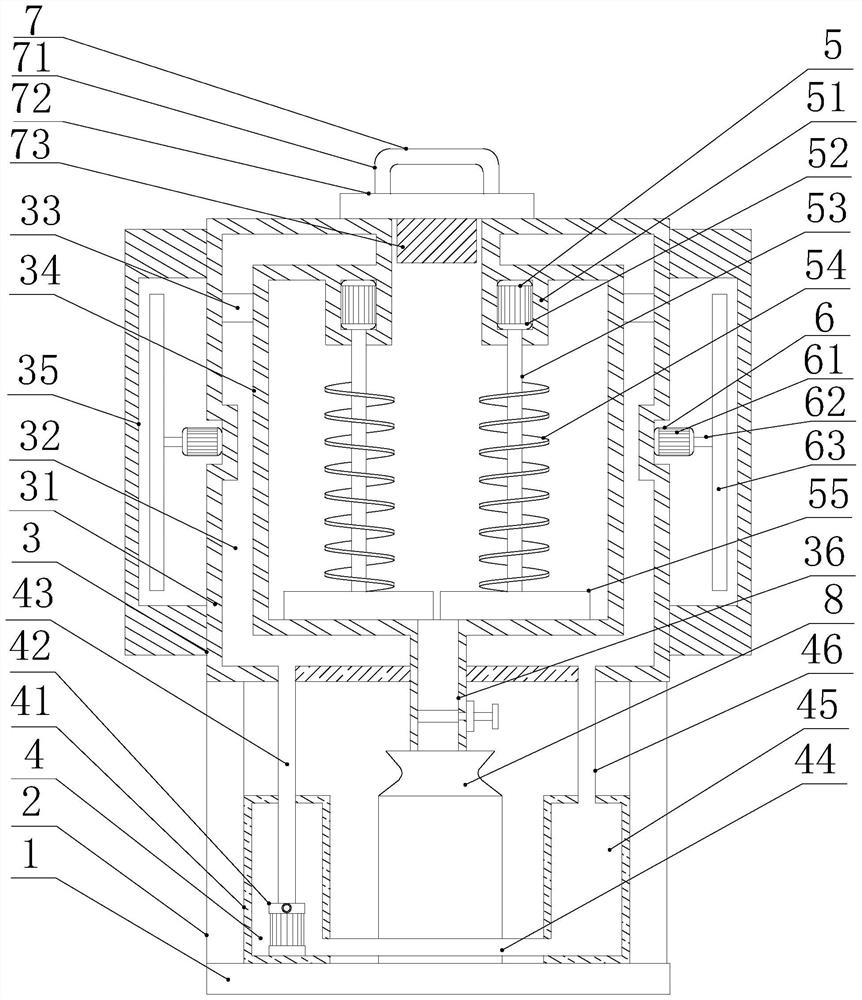

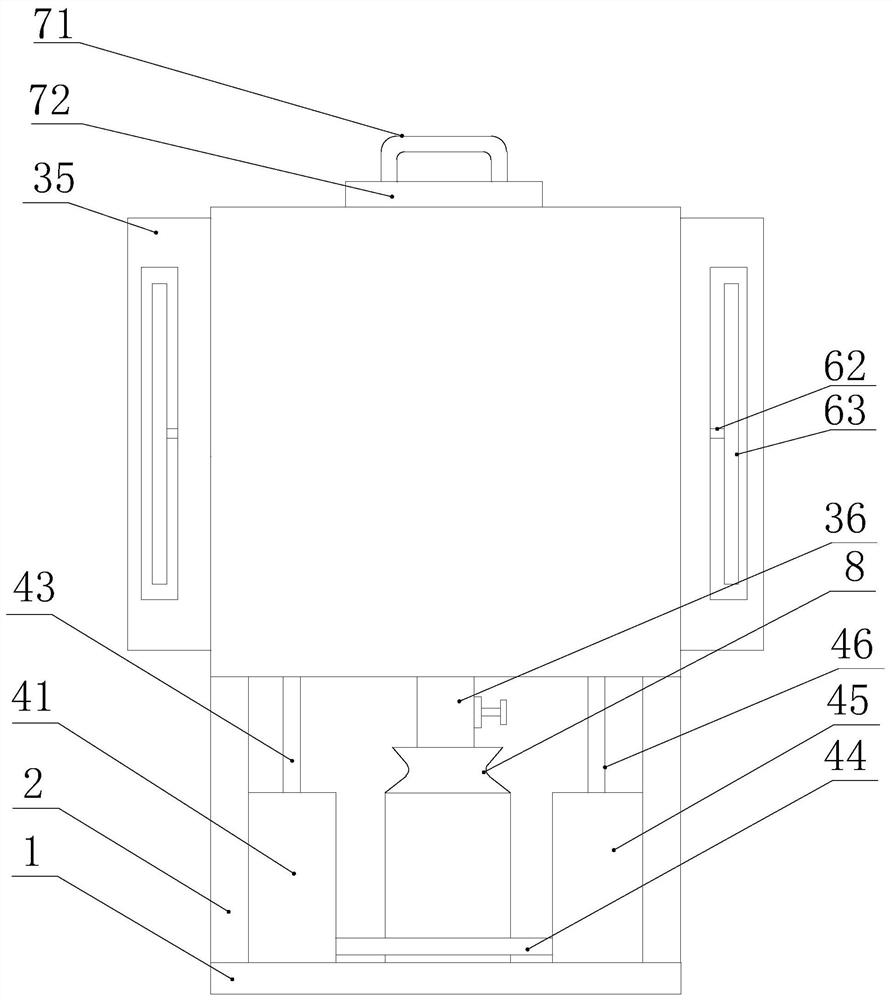

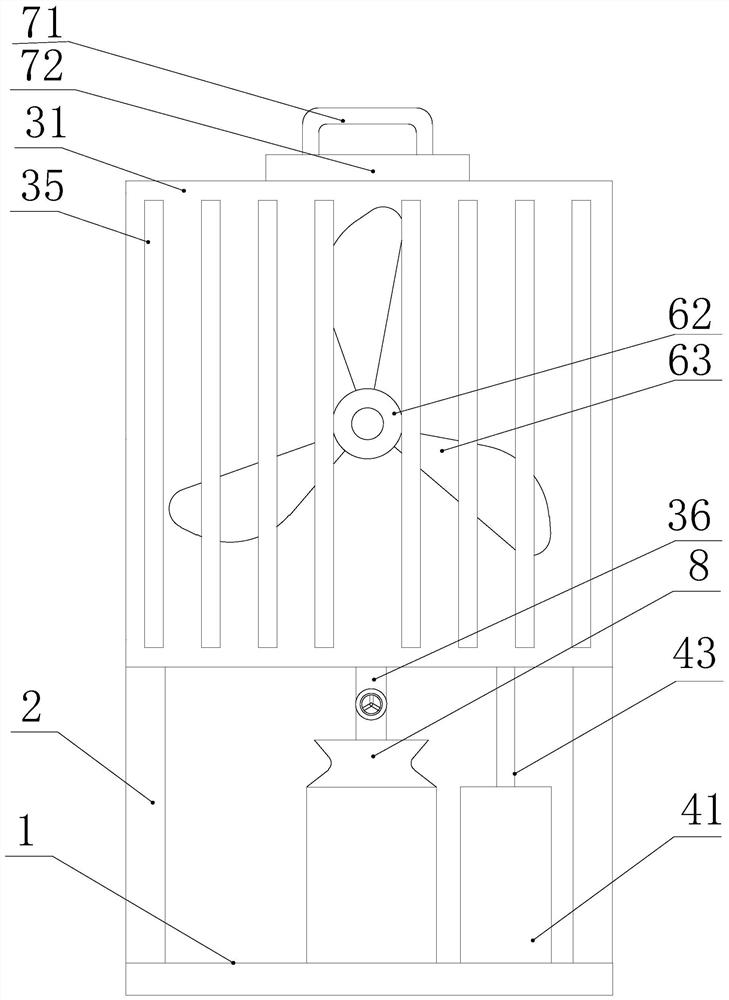

[0024] Example: such as Figure 1-5 As shown, a cooling device in a liquid sorbitol production process of the present invention includes a base 1, the top of the base 1 is fixedly connected with a support column 2, the top of the support column 2 is provided with a protection mechanism 3, and the top of the base 1 is provided with an infusion mechanism 4, The inside of the protection mechanism 3 is provided with a stirring mechanism 5, the outside of the protection mechanism 3 is provided with a heat dissipation mechanism 6, the top of the protection mechanism 3 is provided with a closing mechanism 7, and the bottom of the protection mechanism 3 is provided with a storage tank 8. The protection mechanism 3 includes a casing 31, and the inside of the casing 31 A cooling cavity 32 is provided to facilitate the cooling cavity 32 to be filled with cooling liquid and to cool the liquid sorbitol in the inner shell 34. The outer shell 31 is fixedly connected with a support block 33, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com